A bi for full solar spectrum response 2 o 2.75 /bio 2-x Composite photocatalyst and its preparation method and application

A technology of solar spectrum and composite light, which is applied in the field of Bi2O2.75/BiO2-x composite photocatalyst and its preparation, can solve the problems of difficulty in using far-infrared light and low utilization rate of sunlight, and achieve simple process and high utilization rate , the effect of good application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

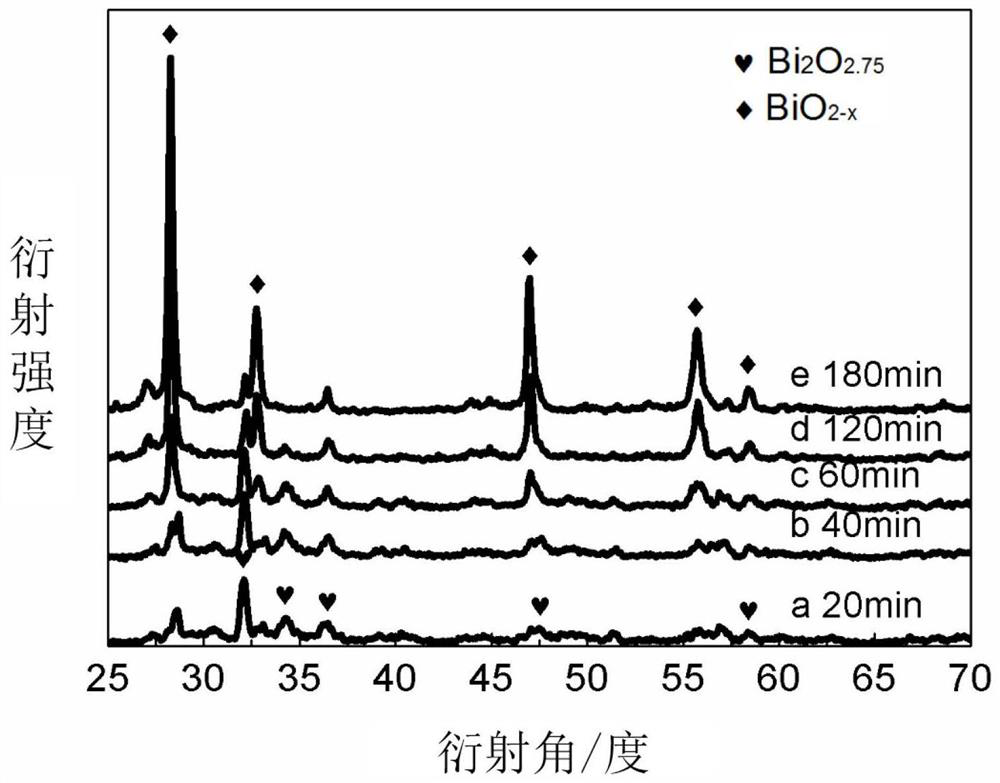

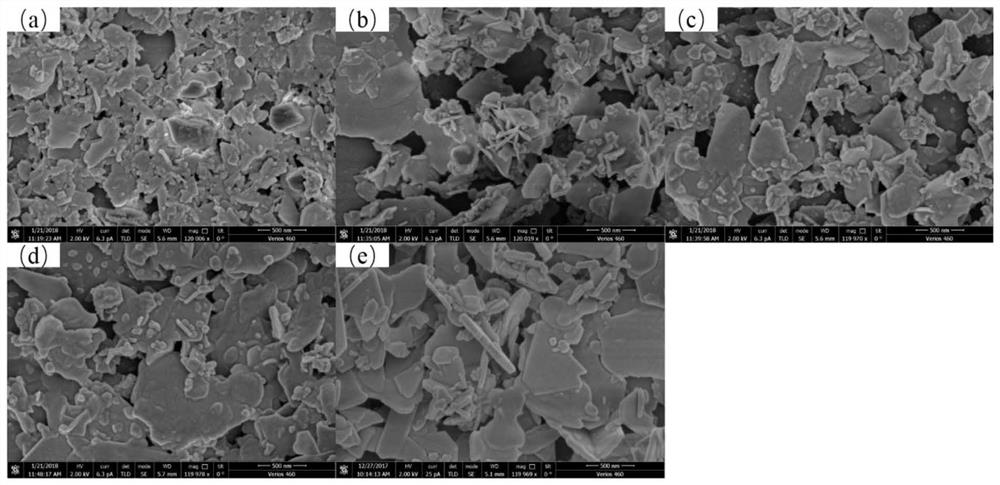

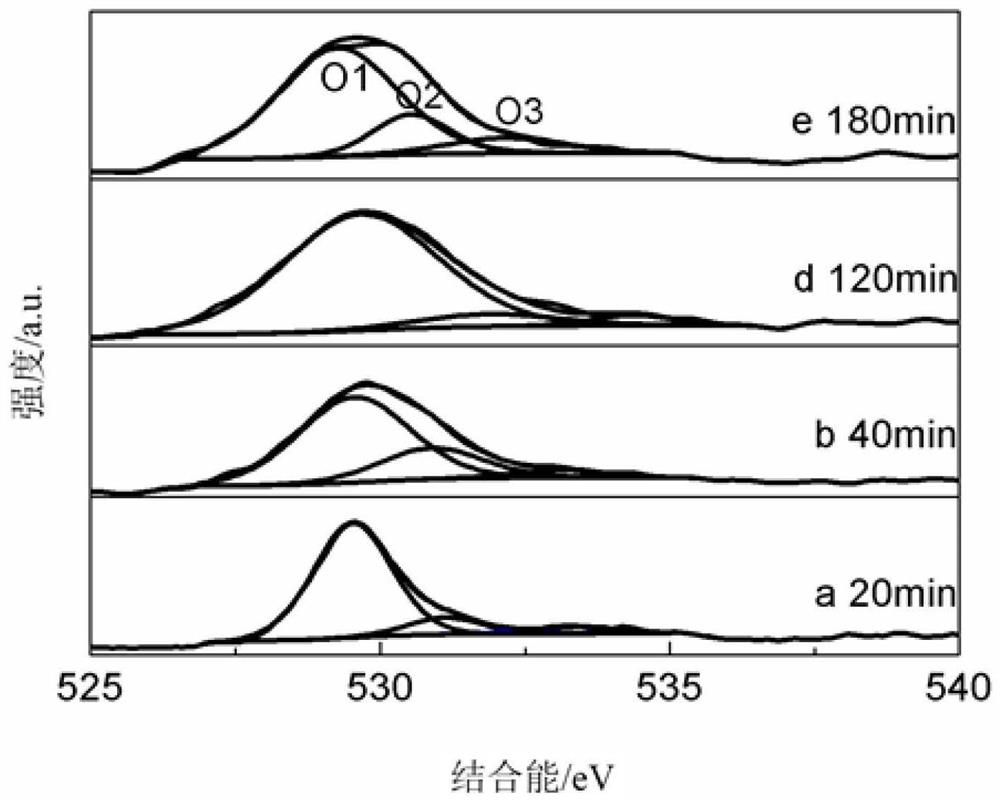

[0041] Step 1: Dissolve 0.5g NaBiO3 powder into 20mL 3.0mol / L NaOH solution, and magnetically stir to obtain A solution;

[0042] Step 2: Slowly disperse the A solution into 20mL deionized water under the condition of magnetic stirring to obtain the reaction precursor;

[0043] Step 3: Add the reaction precursor solution into the hydrothermal reaction kettle, place the hydrothermal reaction kettle in a hydrothermal synthesizer, and react at 170° C. for 20 minutes; wherein, the filling ratio of the reaction precursor solution is 60%.

[0044] Step 4: After the reaction is completed, cool naturally to 70°C, take out the precipitate in the hydrothermal reaction kettle, wash with deionized water and absolute ethanol, and finally dry at a constant temperature at 70°C to obtain Bi2O2.75 / BiO2-x composite catalyst of light.

Embodiment 2

[0046] Step 1: Dissolve 0.5g NaBiO3 powder into 20mL 3.0mol / L NaOH solution, and magnetically stir to obtain A solution;

[0047] Step 2: Slowly disperse the solvent A into 20mL deionized water under the condition of magnetic stirring to obtain the reaction precursor;

[0048] Step 3: Add the reaction precursor liquid into the hydrothermal reaction kettle, place the hydrothermal reaction kettle in the hydrothermal synthesizer, and react at 170°C for 40 minutes; wherein, the filling ratio of the reaction precursor solution is 60%;

[0049] Step 4: After the reaction is completed, cool naturally to 70°C, take out the precipitate in the hydrothermal reaction kettle, wash with deionized water and absolute ethanol, and finally dry at a constant temperature at 70°C to obtain Bi2O2.75 / BiO2-x composite catalyst of light.

Embodiment 3

[0051] Step 1: Dissolve 0.5g NaBiO3 powder into 20mL 3.0mol / L NaOH solution, and magnetically stir to obtain A solution;

[0052] Step 2: Slowly disperse the solvent A into 20mL deionized water under the condition of magnetic stirring to obtain the reaction precursor;

[0053] Step 3: Add the reaction precursor solution into the hydrothermal reactor, place the hydrothermal reactor in a hydrothermal synthesizer, and react at 170°C for 60 minutes; wherein, the filling ratio of the reaction precursor solution is 60%;

[0054] Step 4: After the reaction is completed, cool naturally to 70°C, take out the precipitate in the hydrothermal reaction kettle, wash with deionized water and absolute ethanol, and finally dry at a constant temperature at 70°C to obtain Bi2O2.75 / BiO2-x composite catalyst of light.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com