Star-shaped impeller charged lithium battery crusher

A crusher, lithium battery technology, applied in the direction of grain processing, etc., can solve the problem of easy explosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

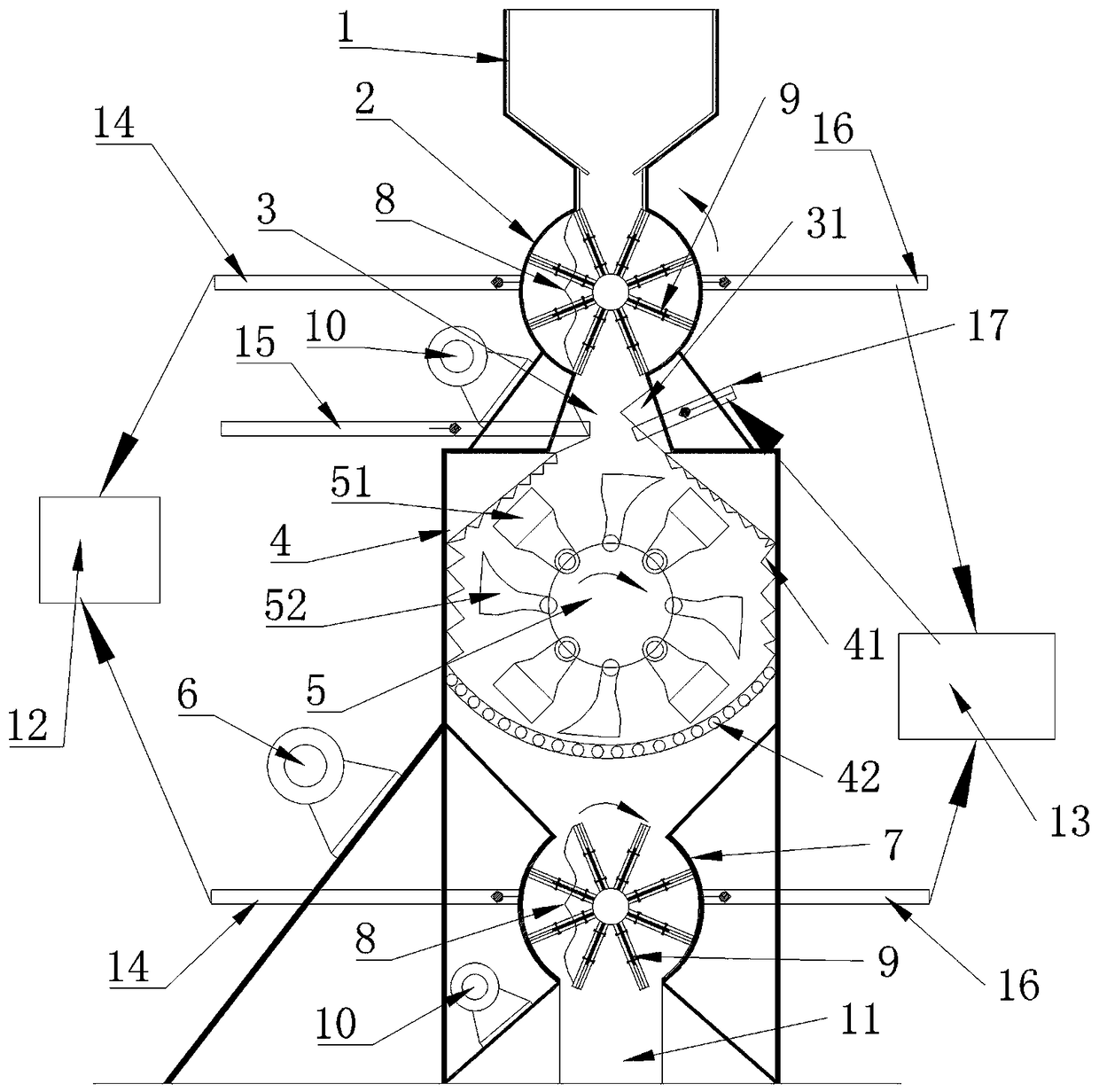

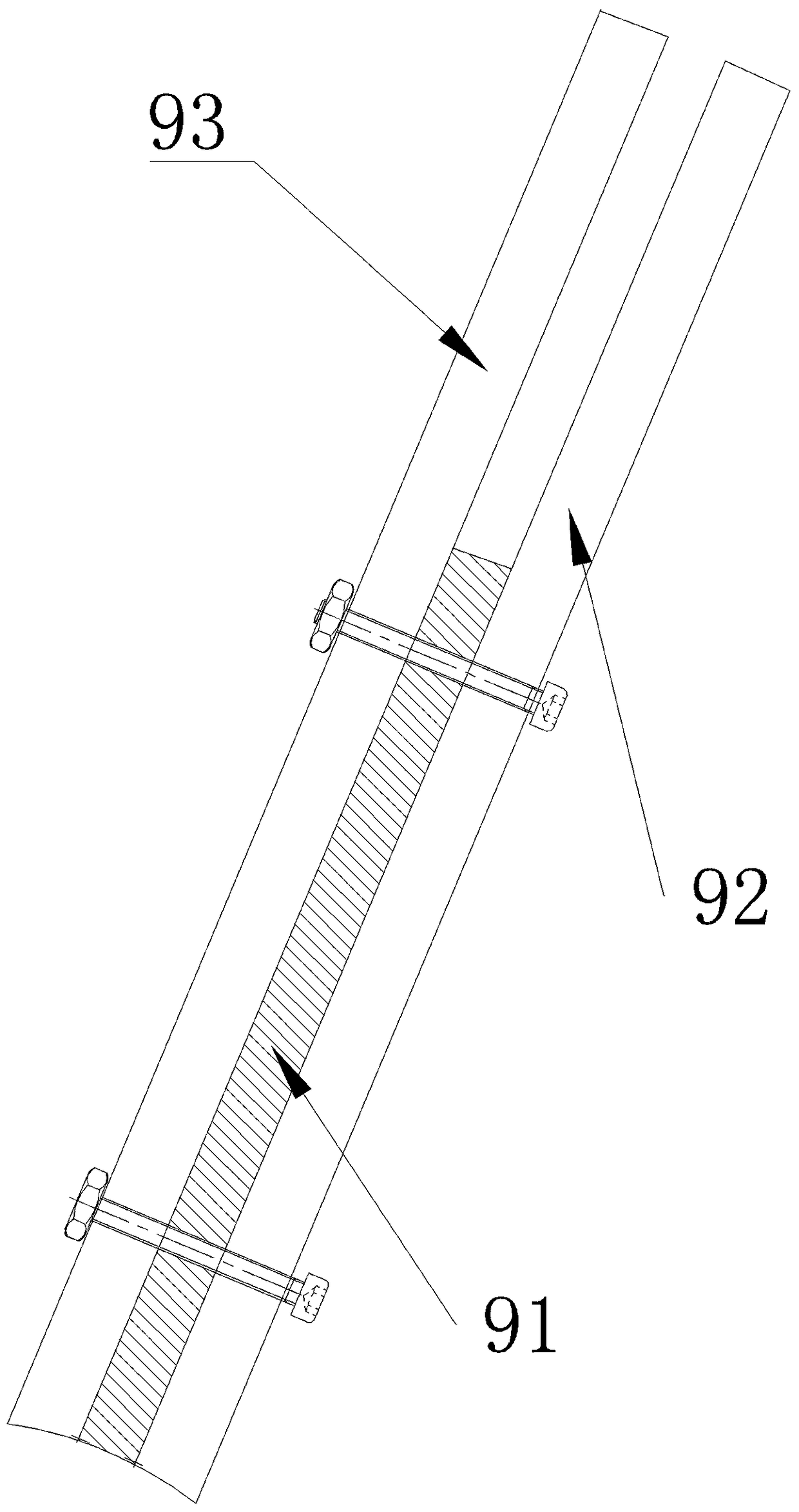

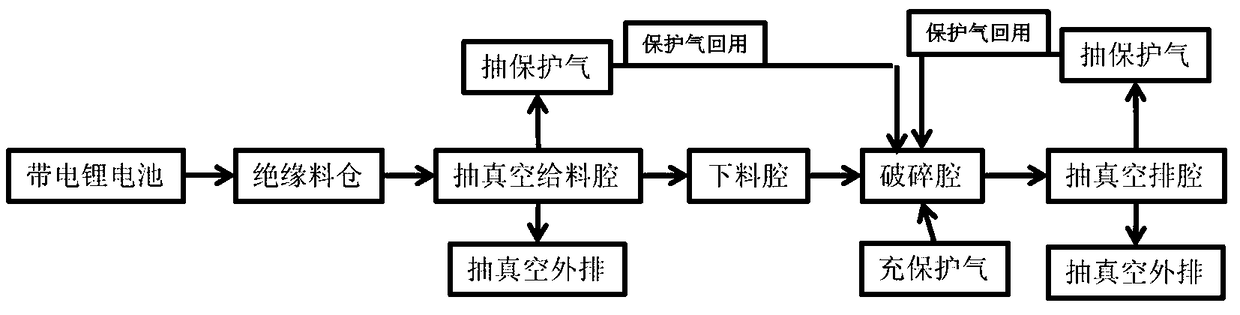

[0023] Embodiment one, such as figure 1 and 2 , a star-shaped impeller 8 charged lithium battery crusher, including an insulating silo 1 above, a vacuum feeding chamber 2 connected below the insulating silo 1, and a crushing chamber 4 below the vacuum feeding chamber 2 , the bottom of the crushing chamber 4 is a vacuum discharge chamber 7, and the bottom of the vacuum discharge chamber 7 is a vertical discharge port 11, and the vacuum feeding chamber 2 and the vacuum discharge chamber 7 pass through The vacuum tube 14 is connected with a vacuum pump 12. The crushing chamber 4 is filled with protective gas. The vacuum feeding chamber 2 is a cylindrical structure with connection ports on the top and bottom. The inside of the vacuum feeding chamber 2 A star-shaped impeller 8 is provided, and the star-shaped impeller 8 includes a plurality of evenly distributed composite blades 9, the edges of the composite blades 9 are close to the inner wall of the vacuum feed chamber 2, and th...

Embodiment 2

[0025] Embodiment two, such as figure 1 , basically the same as the first embodiment, the difference is that a feeding chamber 3 is connected between the vacuum feeding chamber 2 and the crushing chamber 4, and one side of the feeding chamber 3 is connected with a protective gas The original protective gas pipe 15 of the source, the middle part of one side of the vacuum feeding chamber 2 is connected with the vacuum pumping pipe 14, and the middle part of the other side is connected with a recovery protective gas pipe 16, and one side of the vacuum discharge chamber 7 The middle part is connected to the vacuum pumping pipe 14, and the middle part on the other side is also connected to a recovery protection gas pipe 16. The recovery protection gas pipe 16 communicates with the air inlet of the protection gas circulation pump 13, and the gas outlet of the protection gas circulation pump 13 A reusable protective gas pipe 17 communicating with the other side of the feeding cavity ...

Embodiment 3

[0027] Embodiment three, such as figure 1 , which is basically the same as Embodiment 1 or Embodiment 2, except that the left side of the vacuum feeding chamber 2 is connected to the vacuum pumping pipe 14, and the right side is connected to the recovery protective gas pipe 16, and the vacuum exhaust The left side of the material chamber 7 is connected to the vacuum pumping pipe 14, and the right side is connected to the recovery protection gas pipe 16. The star-shaped impeller 8 in the vacuum feeding chamber 2 rotates counterclockwise, and the vacuum discharge chamber 7 The star impeller 8 rotates clockwise.

[0028] In specific operation, the insulating silo 1 can be made of insulating materials such as outer metal and inner insulating plastic (the silo can be entirely made of insulating materials). Before entering the silo, the charged lithium battery must be dehydrated to prevent moisture from entering the crusher. In the crushing chamber, the crusher vacuumizes the lithi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com