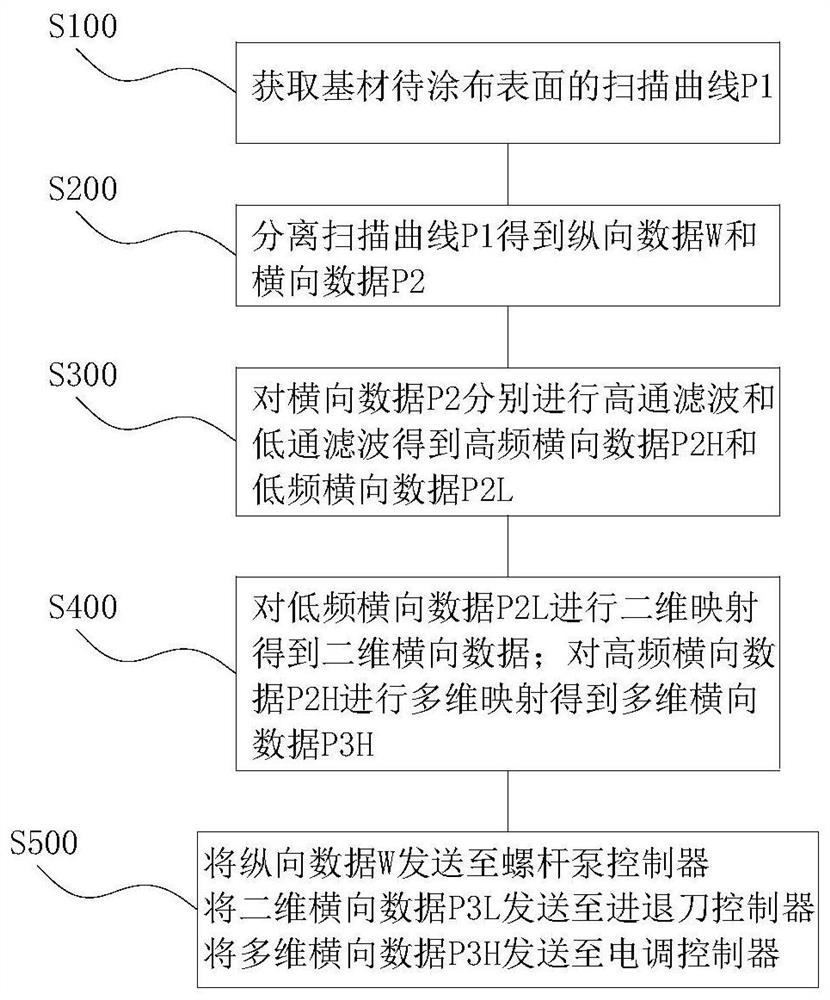

A method of controlling coating amount

A coating amount and coating technology, which is applied to the device and coating of the surface coating liquid, can solve the problems of waste, increase the difficulty of manual operation, and difficult adjustment, so as to improve product quality and be suitable for popularization and use , to avoid the effect of mechanical deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

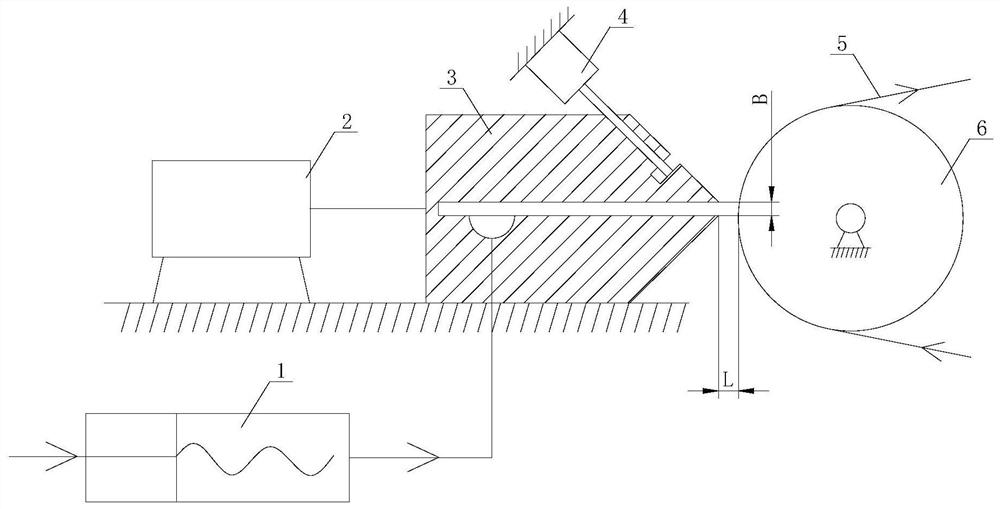

[0043] For the convenience of illustrating the specific process of the method for controlling the amount of coating in this embodiment, a coating machine is provided in this embodiment, specifically, please refer to figure 2 , the mixed slurry enters the screw pump 1 through the feed port of the screw pump 1, the screw pump 1 is connected with a screw pump controller controlling the output flow of the screw pump 1, and the screw pump controller controls the screw pump 1 to pump out the slurry, The pumped slurry enters the coating die 3 through the feed port of the coating die 3, and then is coated on the substrate 5 through the discharge port of the coating die 3; the back roller 6 realizes the transportation of the substrate 5. In this embodiment, the screw pump 1 is driven by a third servo motor, and the screw pump controller is a third servo driver that controls the third servo motor. The coating die head 3 is connected with an advancing and retreating knife adjusting mech...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com