Wood dust recovery device for achieving multistage separation and sand removal

A multi-stage separation and dust recovery technology, applied in the direction of solid separation, separation of solids from solids with airflow, chemical instruments and methods, etc., can solve the problem of inability to automatically transfer sand and impurities, uncontrollable sand separation effect, and air velocity Can not be adjusted and other problems, to achieve the effect of simple structure, good sand removal effect, easy to process and manufacture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

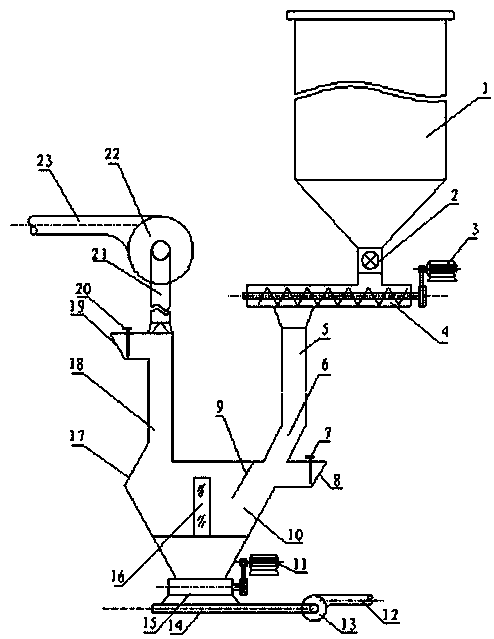

[0037] Such as figure 1 As shown, a wood dust recovery device with multi-stage separation and desanding is mainly composed of wood dust bin 1, discharge rotary valve I2, motor I3, feeding screw 4, vertical feeding pipe 5, inclined feeding pipe 6, sand separation Chamber 10, motor II11, fan I13, sand and impurity conveying pipe 14, discharge rotary valve II15, vertical sand separation pipe 18, wood dust conveying pipe I21 and fan II22; the discharge rotary valve I2 is installed in the wood dust bin 1 and the feeding screw 4; one end of the feeding screw 4 is connected with the power output shaft of the motor I3, and the other end of the feeding screw 4 is connected with one end of the vertical feeding pipe 5; the vertical feeding pipe 5 The other end communicates with the sand separation chamber 10 through the inclined feeding pipe 6; the discharge rotary valve II15 is installed between the sand separation chamber 10 and the sand and impurity delivery pipe 14, and the control e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com