Steel wire mesh skeleton plastic composite tube constant-temperature heating device and application method thereof

A compound pipe and constant temperature heating technology, which is applied in the field of plastic pipe processing, can solve the problems of the difference in peeling strength of the pipe and the large difference in the ambient temperature between day and night, and achieve the effect of adjustable heating temperature, real-time adjustment of the heating temperature, and constant pipe temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

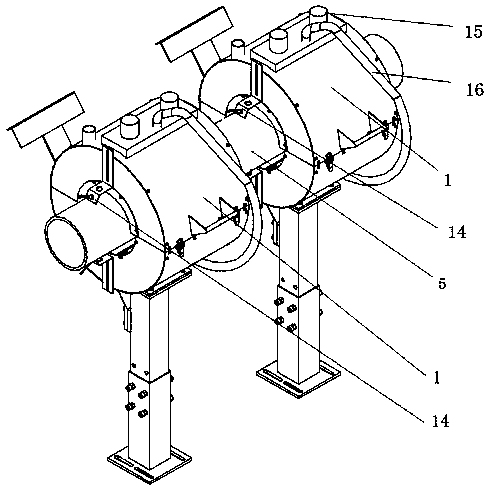

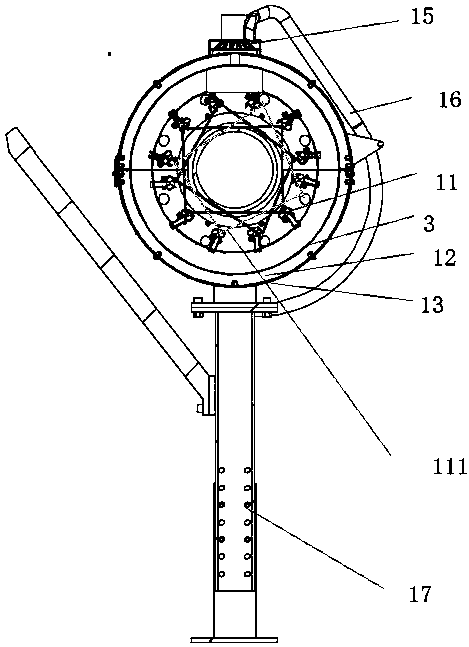

[0024] like Figures 1 to 2 Shown is an embodiment of a constant temperature heating equipment for steel mesh skeleton plastic composite pipes of the present invention. The heating equipment includes two sets of heating mechanisms 1 arranged in the middle of the heating equipment and at the outlet end. The heating mechanism 1 includes heating pipes 11 arranged sequentially from the inside to the outside. , thermal insulation layer 12, stainless steel shell 13, heating mechanism 1 is provided with the temperature detector 14 that is used to detect pipe temperature, and heating mechanism 1 is provided with controller, and controller is all electrically connected with heat pipe 11, temperature detector 14. The launch tube 11 is arranged on the inner layer 3 .

[0025] Wherein, the heating mechanism 1 is provided with a blower fan 15 and a blower duct 16 for preventing temperature unevenness, and the blower fan 15 and the blower duct 16 are connected.

[0026] In addition, the ai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com