3D printer flexible platform

A 3D printer and flexible platform technology, applied in the field of machinery, can solve problems such as laboriousness and easy deformation of the platform, and achieve the effect of simple structure, convenient pick and place operation, and reduced operation difficulty.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

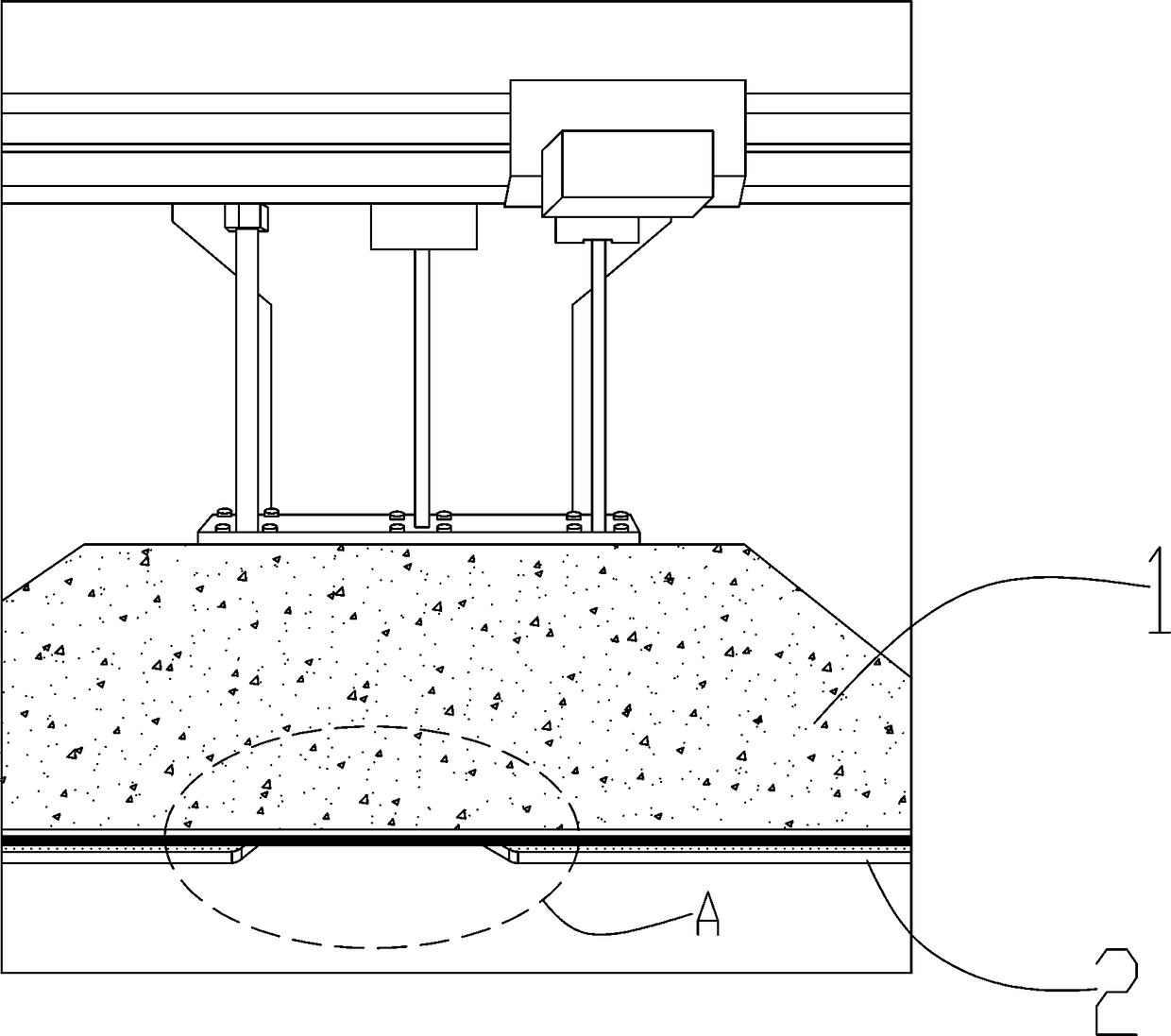

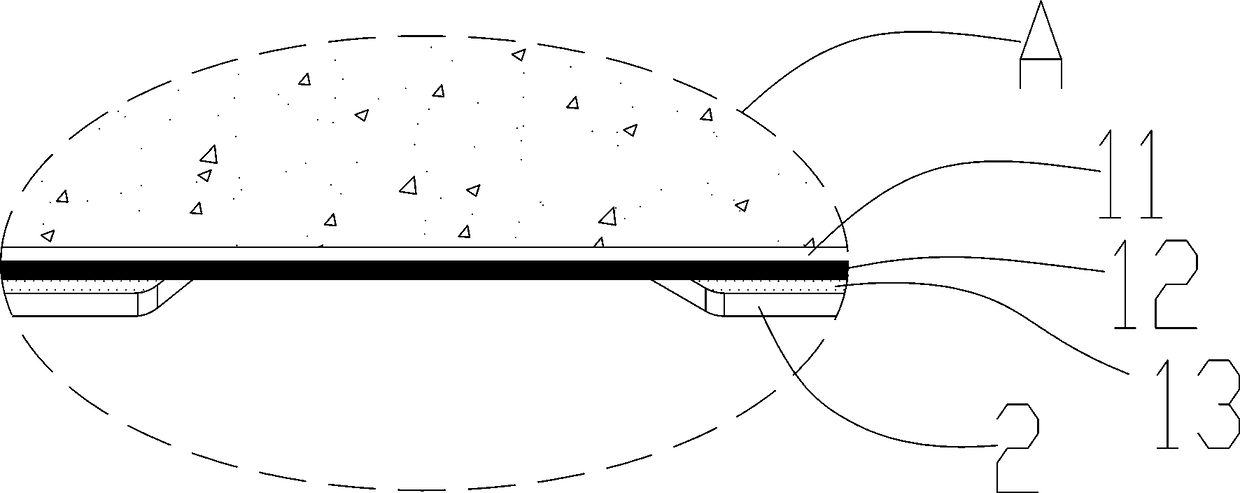

[0026] Such as Figure 1~5 As shown, a flexible platform for a 3D printer, the flexible platform 1 sequentially includes a flexible magnetic sheet 13 fixed on the lifting platform 2 from bottom to top, a metal support layer 12 adsorbed on the flexible magnetic sheet 13, and attached to the metal The printed sticker 11 on the supporting layer 12; the flexible magnetic sheet 13 has a flat surface and can be cut; the metal supporting layer 12 has a flat surface; the printed sticker 13 has a flat surface.

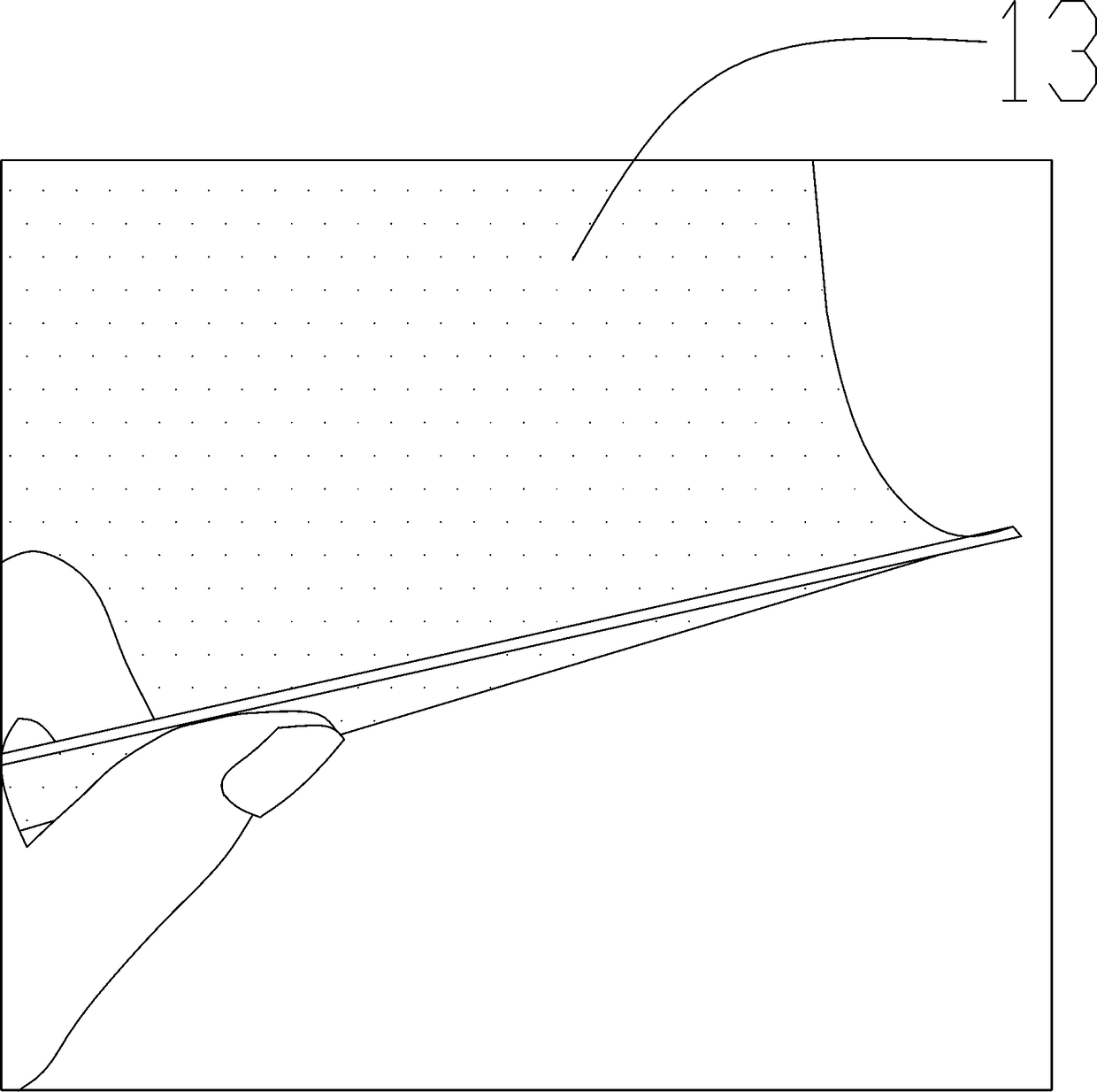

[0027] Further, the flexible magnetic sheet 13 is made of a flat flexible magnetic sheet made of a magnetic material. The flexible magnetic sheet 13 of the present invention is made of a soft magnetic material. The flexible magnetic sheet 13 can be cut and cut arbitrarily, and can also be subjected to It is bent under the action of external force and has flexibility. Further, a notch is provided on the flexible magnetic sheet 13, the metal support layer 12 is adsorbed on the f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap