Weaving equipment for planar tri-axial fabric and method

A three-way fabric and equipment technology, applied in the field of fabric weaving, can solve the problems of increased broken ends, complex mechanical structure, high production cost, etc., and achieve the effect of improving quality and performance, reducing production cost, and preventing yarn breakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

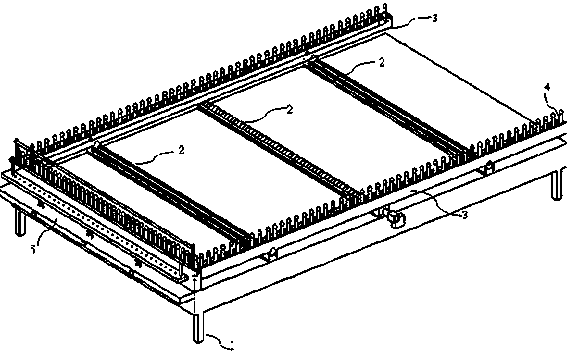

Embodiment 1

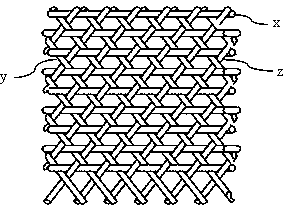

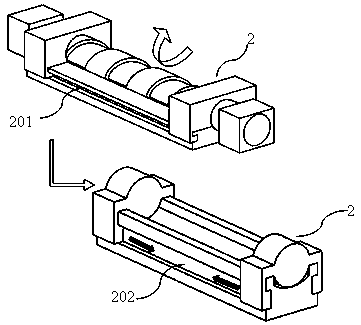

[0042] This equipment is used to weave a plane three-way fabric (plain basic weave), which is composed of two sets of warp yarn systems y, z and one set of weft yarn system x. The oblique warp yarn is T300-1K carbon fiber, the weft yarn is T300-3K carbon fiber, the angle between the warp and weft yarn is 60°, Px=Pz=25 threads / 10cm, the width and fabric length of the woven flat three-way fabric are respectively 600mm, 20000mm. Five cylindrical needles are arranged in a single needle row board, the distance between the horizontal yarn hanging guide rails is 600mm, the distance between the cylindrical needles in the needle row board is 100mm, and the required number of horizontal needle rows is 7. The length of the weaving platform is 6000mm, and the distance between longitudinal cylindrical needles is 170mm. Longitudinal yarn hanging guide cylinder needle row board completes 24 cycles. The number of oblique warp yarns required is 5,700, and the number of weft yarns required is 5...

Embodiment 2

[0044] The equipment is used to weave biaxial bias fabric, which is composed of one set of warp yarn system y and one set of weft yarn system yarn x. The oblique warp yarn is T300-1K carbon fiber, the weft yarn is T300-3K carbon fiber, the angle between the warp and weft yarns is 60°, Px=Pz=25 strands / 10cm, the width and fabric length of the woven biaxial bias fabric They are 1000mm and 20000mm respectively. Five cylindrical needles are arranged in a single needle row board, the distance between the horizontal yarn hanging guide rails is 1000 mm, the distance between the cylindrical needles in the needle row board is 100 mm, and the number of horizontal cylindrical needles required is 11. The length of the weaving platform is 6000mm, and the distance between the cylindrical needles of the vertical yarn hanging guide rail and the needle row plate is 170mm. Longitudinal yarn hanging guide cylinder needle row board completes 24 cycles. The required number of oblique warp yarns ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com