Tunnel second lining construction joint waterproof structure

A waterproof structure and construction joint technology, applied in the direction of tunnel lining, tunnel, drainage, etc., to achieve the effect of strong operability, significant economic and social benefits, and simple construction steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Specific embodiments of the present invention are provided below, and it should be noted that the present invention is not limited to the following specific embodiments, and all equivalent transformations done on the basis of the technical solutions of the present application all fall within the scope of protection of the present invention.

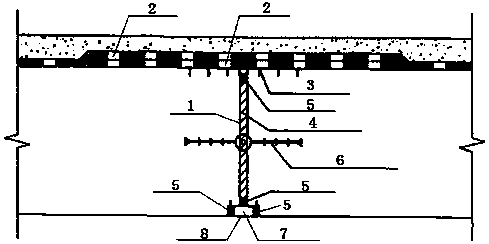

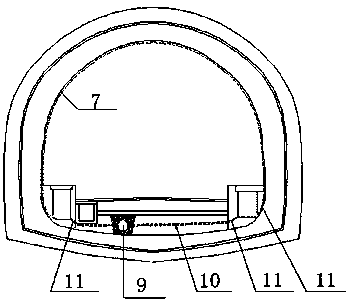

[0016] The present invention provides a waterproof structure for the construction joint of the second lining of the tunnel. Five parts of the waterproof structure are set at the construction joint 1. Compared with the existing post-processing measures, the present invention takes precautions, and the advance processing structure of the present invention is safer and more convenient. , effective, the following will introduce the five-part waterproof structure made at the construction joint 1 one by one:

[0017] The first part: During the construction of the structure, a water receiving box space is reserved inside the construction j...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com