Dredge pump operation maintenance early-warning system

An operation and maintenance, mud pump technology, applied in the field of ships, can solve the problems of enlarged accident losses, accident enlargement, waste of funds, etc., to achieve the effect of reducing operating costs, strong pertinence, and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

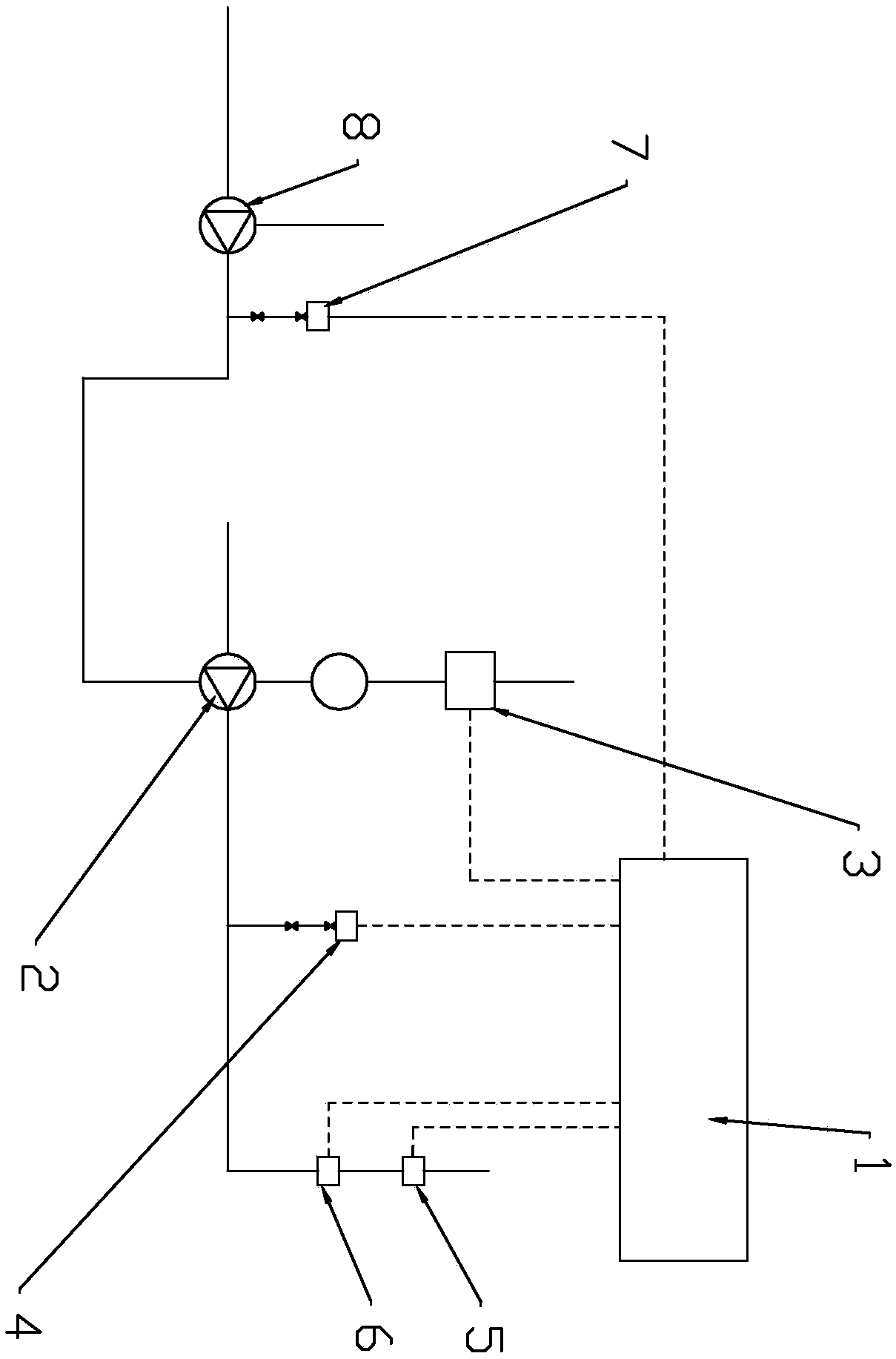

[0022] refer to figure 1 , the present invention is a kind of mud pump operation and maintenance early warning method, comprises the following steps:

[0023] 1) A number of efficiency reference values are set in the central processing unit 1, and the central processing unit 1 communicates with the frequency converter 3 controlling the working state of the mud pump 2 in real time;

[0024] 2) Install a discharge pressure sensor 4, a flow meter 5 and a density meter 6 at the mud output end of the mud pump 2 to form a data detection module, and use the data detection module to detect the discharge pressure value, flow value and mud density value of the mud pump 2 , the discharge pressure sensor 4, the flow meter 5 and the density meter 6 all communicate with the central processing unit 1 in real time;

[0025] 3) The central processing unit 1 calculates the actual output power of the mud pump 2 through the discharge pressure value, flow value and mud density value, and compar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com