Electronic mechanical brake

A mechanical and brake technology, which is applied in the direction of mechanical equipment, brake actuators, gear transmission mechanisms, etc., can solve the problems of unsuccessful application of design schemes, difficult manufacturing and assembly, and large brake volume, so as to reduce assembly costs, The effect of reducing processing costs and improving transmission efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

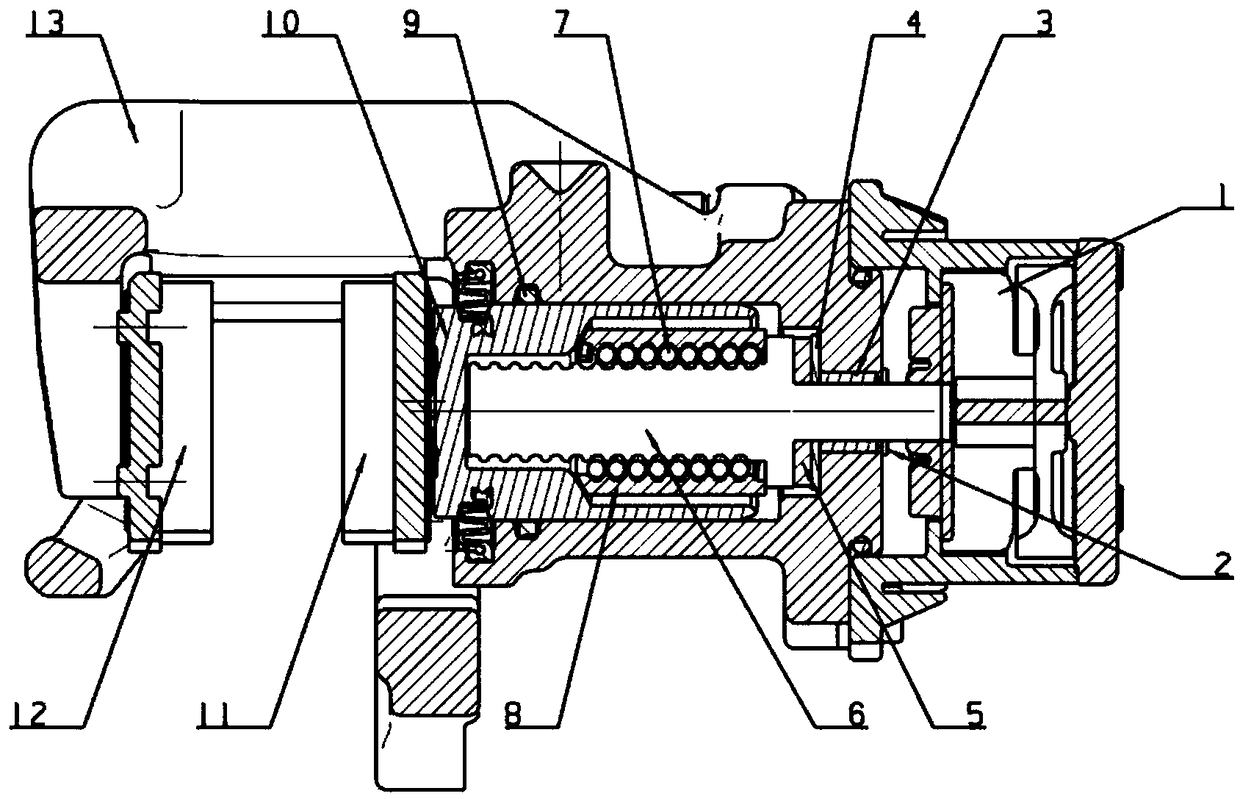

[0035] In order to make it easy to understand the technical means, creative features, goals and effects achieved by the present invention, the following examples are combined with the appended figure 1 to attach Figure 6 An electromechanical brake provided by the present invention is described in detail.

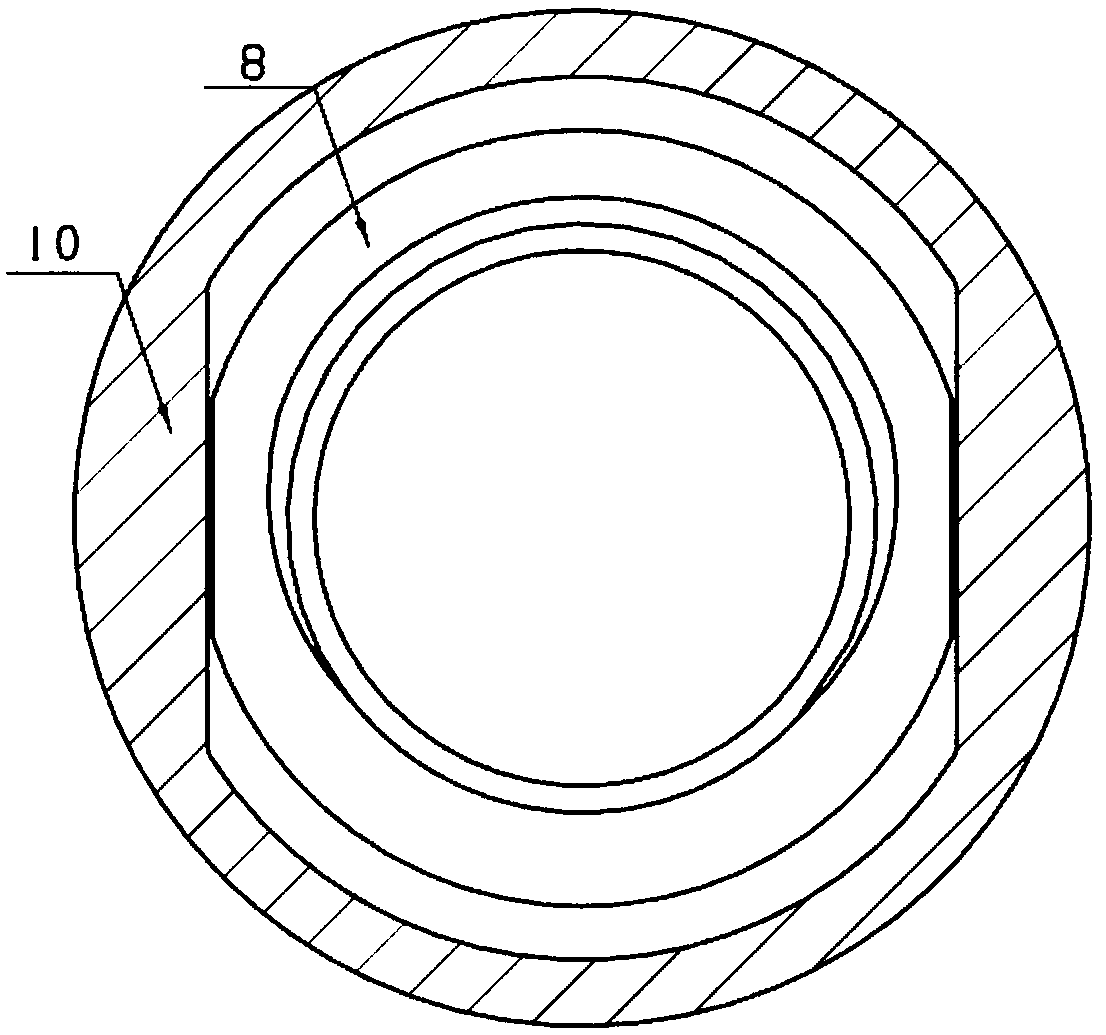

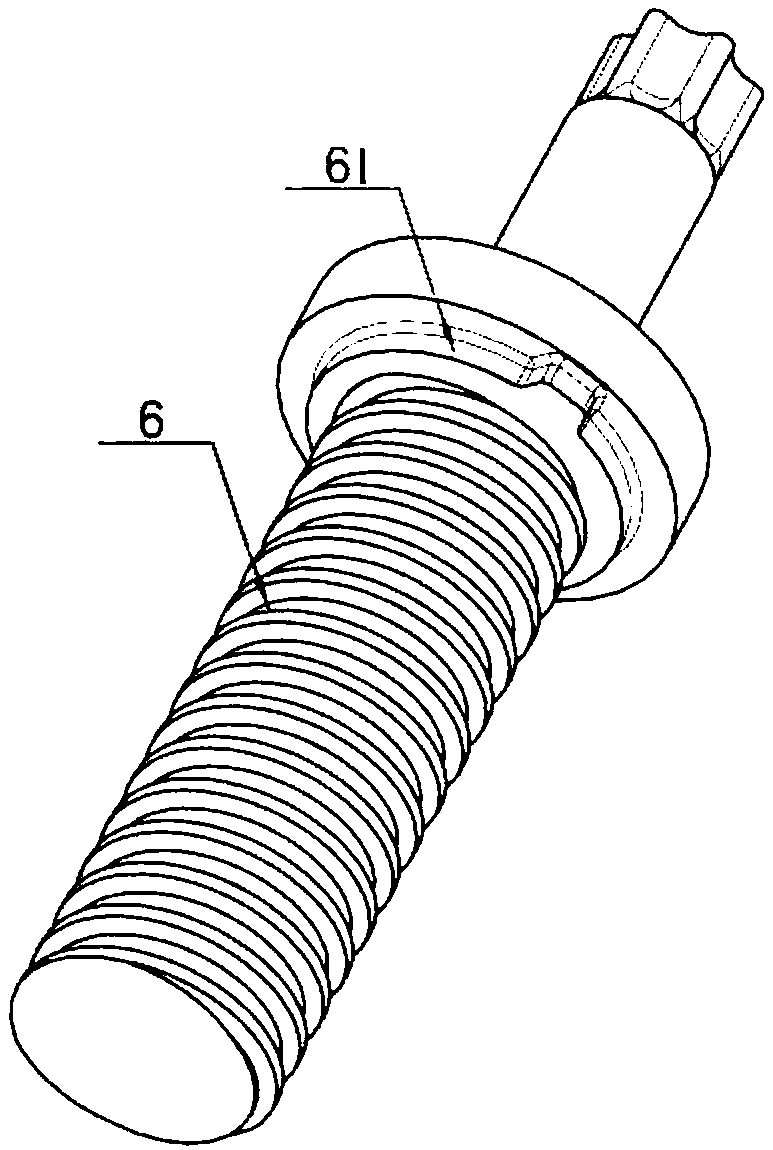

[0036] figure 1 It is a structural schematic diagram of an embodiment of an electromechanical brake of the present invention, figure 2 It is a schematic cross-sectional structure diagram of a nut and a piston in an embodiment of an electromechanical brake of the present invention, image 3 It is a structural schematic diagram of the screw rod in an embodiment of an electromechanical brake of the present invention, Figure 4 It is a structural schematic diagram of a nut in an embodiment of an electromechanical brake of the present invention, Figure 5 It is a structural schematic diagram of the screw and nut anti-rotation mechanism in an embodiment of an electromechanic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com