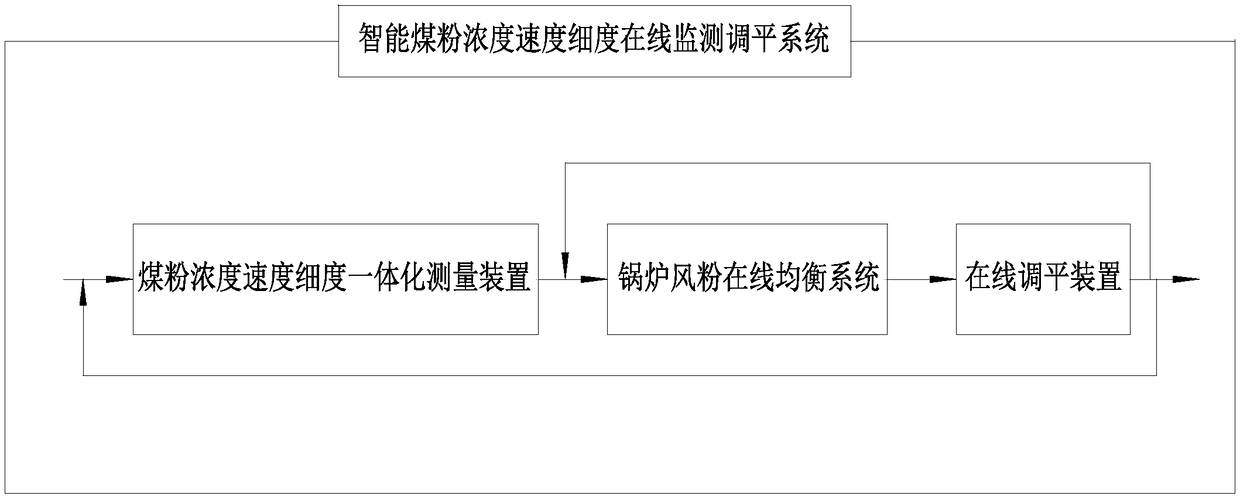

Intelligent pulverized coal concentration, speed and fineness on-line monitoring leveling system and method thereof

A technology of pulverized coal and velocity, applied in the field of intelligent online monitoring and leveling system of pulverized coal concentration, velocity and fineness, which can solve problems such as pipe burst, high temperature corrosion of heating surface, and pulverized coal deposition in horizontal pipelines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

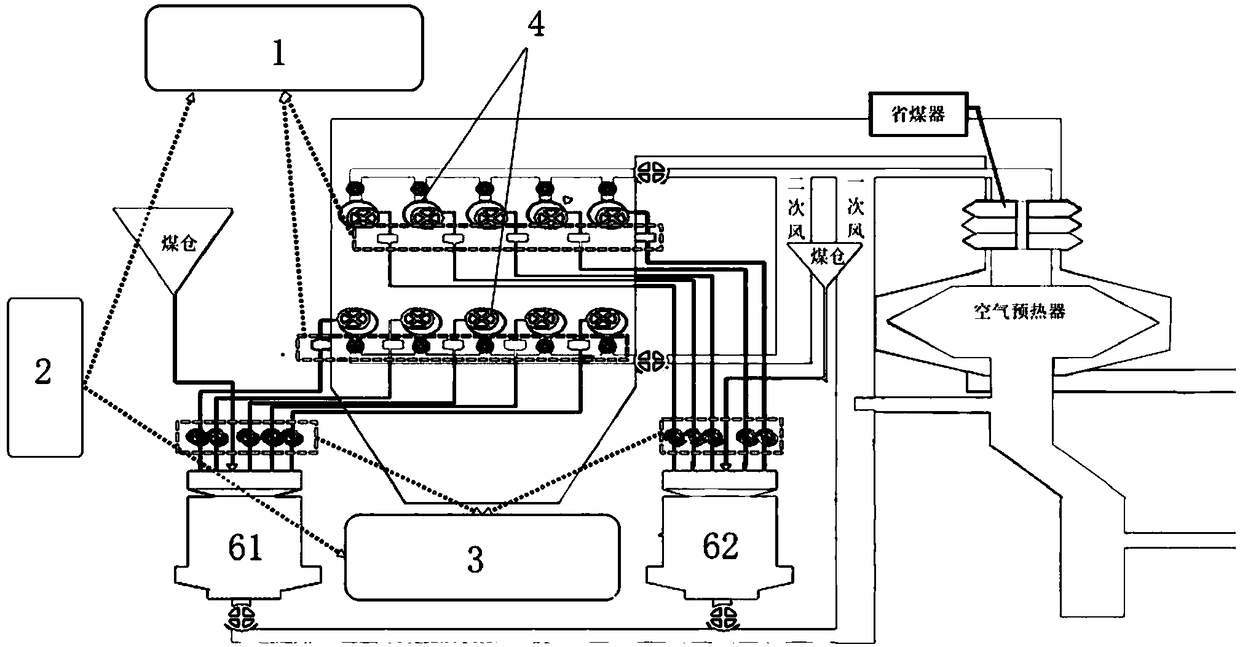

[0022] Example 1: Such as figure 2 The intelligent pulverized coal concentration, speed and fineness on-line monitoring and leveling system shown includes the integrated measurement device for pulverized coal concentration, speed and fineness 1, the on-line leveling device 3, and the boiler air and powder online equalization system 2; the integrated pulverized coal concentration, speed and fineness The measuring device 1 and the online leveling device 3 are respectively installed on the primary powder pipes at the outlets of the coal mills 61 and 62. The integrated measuring device for the concentration, speed and fineness of coal powder is located near the inlet of the boiler 4, and the online leveling device is near the coal mill 61 / 62 outlet setting; all measured data are fed back to the boiler air and powder online equalization system 2 in the local control cabinet, and the boiler air and powder online equalization system 2 analyzes and transmits the data, and all measured ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com