Large-section flue SCR-CEMS (selective catalytic reduction-continuous emission monitoring system) flue gas multi-point equal-mixing two-stage ejecting rapid sampling device and method thereof

A technology of SCR-CEMS and equal mixing, which is applied in the direction of sampling devices, etc., can solve the problems of reducing the representativeness of single-point sampling and CEMS analysis values, not ensuring equal sampling, and affecting the representativeness of sampling, etc., to shorten the detection lag time , Improve response followability, improve the effect of ammonia injection regulation followability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

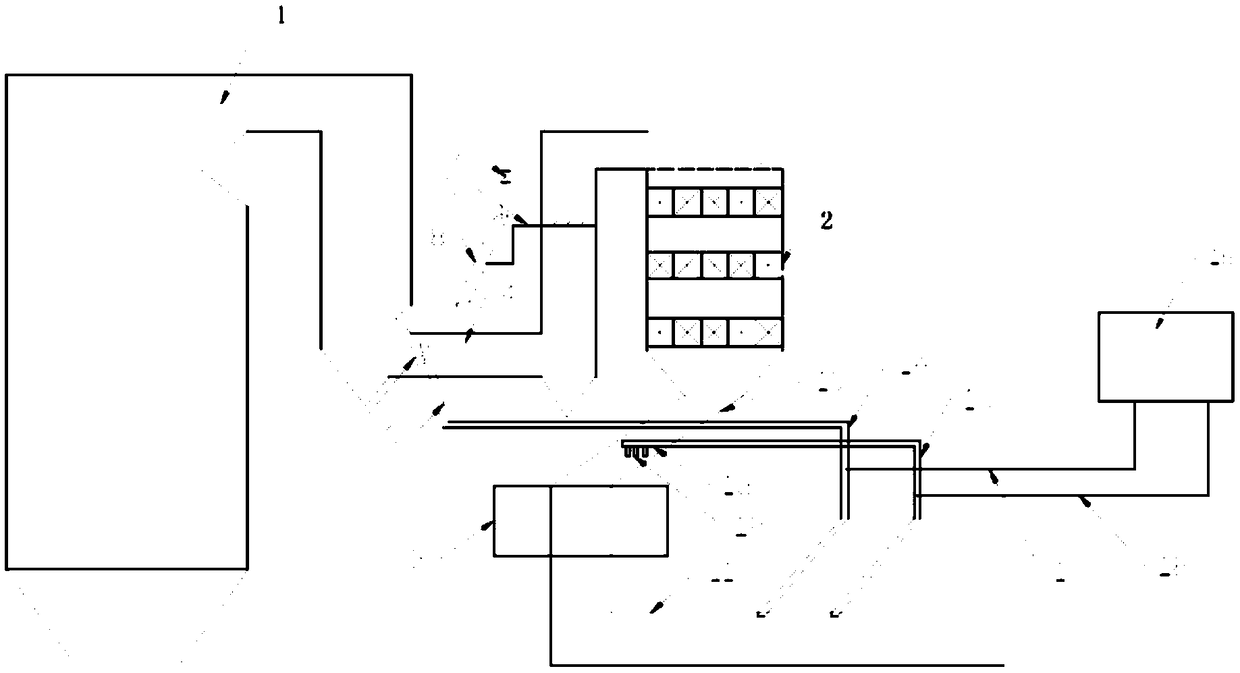

[0037] Such as figure 1 As shown, a large cross-section flue SCR-CEMS flue gas multi-point equal-volume mixing secondary injection rapid sampling device in this embodiment includes boiler 1, SCR reactor 2 and air preheater 3 connected in sequence, boiler 1 An SCR inlet flue 4 is provided between the SCR reactor 2 and an SCR outlet flue 10 is provided between the SCR reactor 2 and the air preheater 3, and an air preheater outlet flue 11 is provided at the outlet of the air preheater 3;

[0038] The SCR inlet flue 4 is equipped with an AIG ammonia injection grill 9, and the large-sized cross-sections of the SCR inlet flue 4 and the SCR outlet flue 10 upstream of the AIG ammonia injection grill 9 are respectively provided with inlet flue gas sampling along the furnace width direction. Branch pipe 5 and outlet flue gas sampling branch pipe 12;

[0039] The inlet flue gas sampling branch pipe 5 communicates with the inlet flue gas sampling manifold 6 located outside the SCR inlet ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com