Vibrating type viscometer and liquid viscosity detection method thereof

A detection method and vibration technology, applied in the direction of instruments, flow characteristics, measuring devices, etc., can solve problems such as unstable measurement results and achieve stable test results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

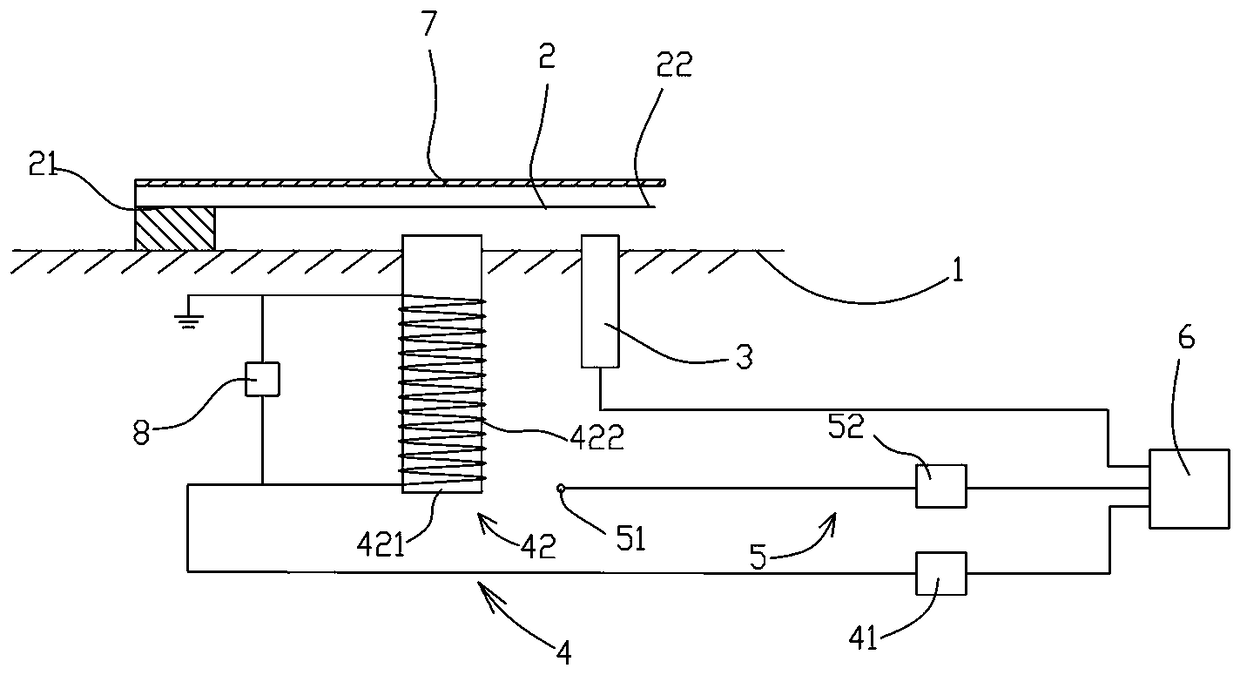

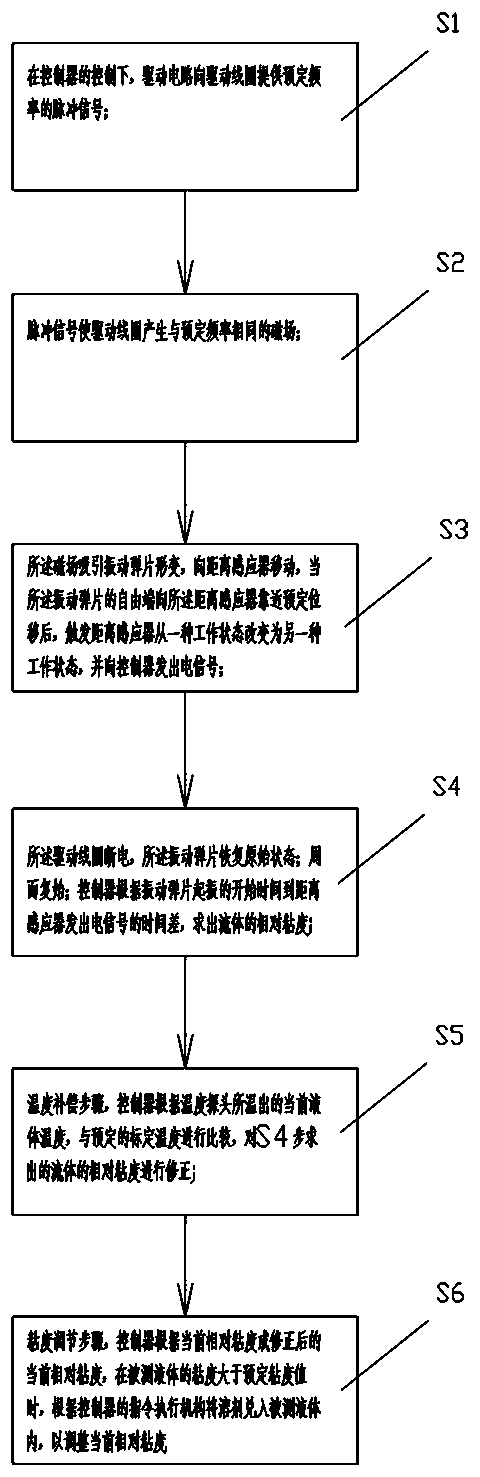

[0031] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0032] The working principle of the present invention is:

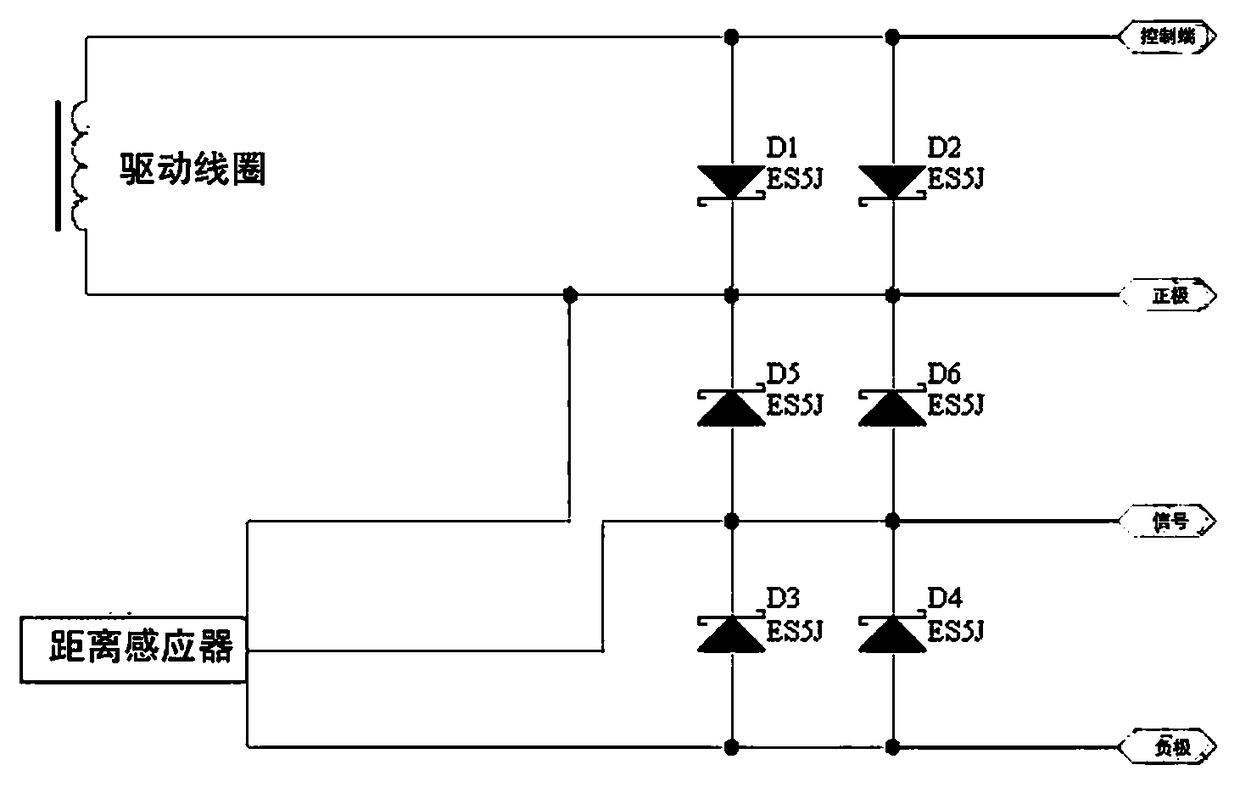

[0033] When a rectangular pulse signal with a predetermined frequency is input to the drive coil, the drive coil will generate a magnetic field due to electrification, and the magnetic field will attract the vibration shrapnel to deform, and the vibration shrapnel will move to the distance sensor. When the free end of the vibration shrapnel moves to the distance After the sensor is close to the predetermined displacement, the trigger distance sensor changes from one working state to another, and sends an electric signal to the controller, and the controller controls the driving coil to cut off the power immediately. The vibrating shrapnel returns to its original state. Repeatedly, the vibrating shrapnel vibrates all the time. The controller calculates the visc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com