Simple testing method of bonding firmness of coating layer and substrate of heat-sensitive paper

A technology combining firmness and testing methods, applied in measuring devices, analytical materials, instruments, etc., can solve the problems of judging the firmness of the bond between the coating layer of thermal paper and the substrate, no corresponding comparison data, and long testing time period, etc. Achieve the effects of convenient retrieval and inspection, intuitive effect and low instrument cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

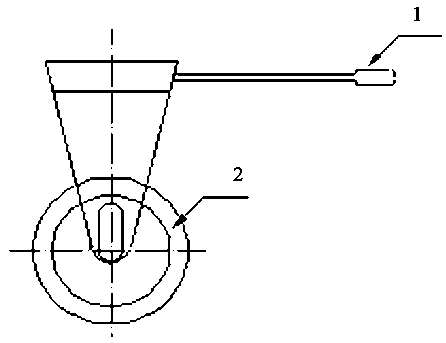

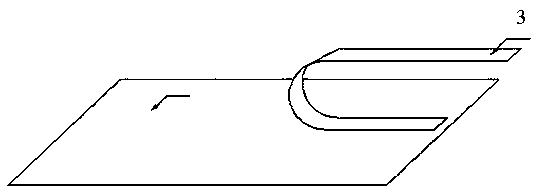

[0020] The present invention is described in further detail now in conjunction with accompanying drawing. These drawings are all simplified schematic diagrams, which only illustrate the basic structure of the present invention in a schematic manner, so they only show the configurations related to the present invention.

[0021] Such as figure 2 As shown, a simple test method for the bonding firmness of the coating layer of thermal paper and the substrate, including the following steps:

[0022] (1) Keep the surface of the thermal paper clean, cut out a thermal paper with a size of 297mm×297mm and marked with vertical and horizontal characters, lay it flat on the soft cloth layer of the backing board and keep the coating layer of the thermal paper upward;

[0023] (2) Put the adhesive surface of the tape 3 close to the upper surface of the thermal paper and naturally flatten it on the upper surface of the thermal paper along the transverse direction of the thermal paper, use ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com