A Method for Optimal Tuning of Load Controller Parameters for Unit Units

A unit unit, load control technology, applied in electric controllers, controllers with specific characteristics, etc., can solve the problems of limited adjustment ability, unsatisfactory effect, and large optimization range setting, and achieve the effect of improving efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

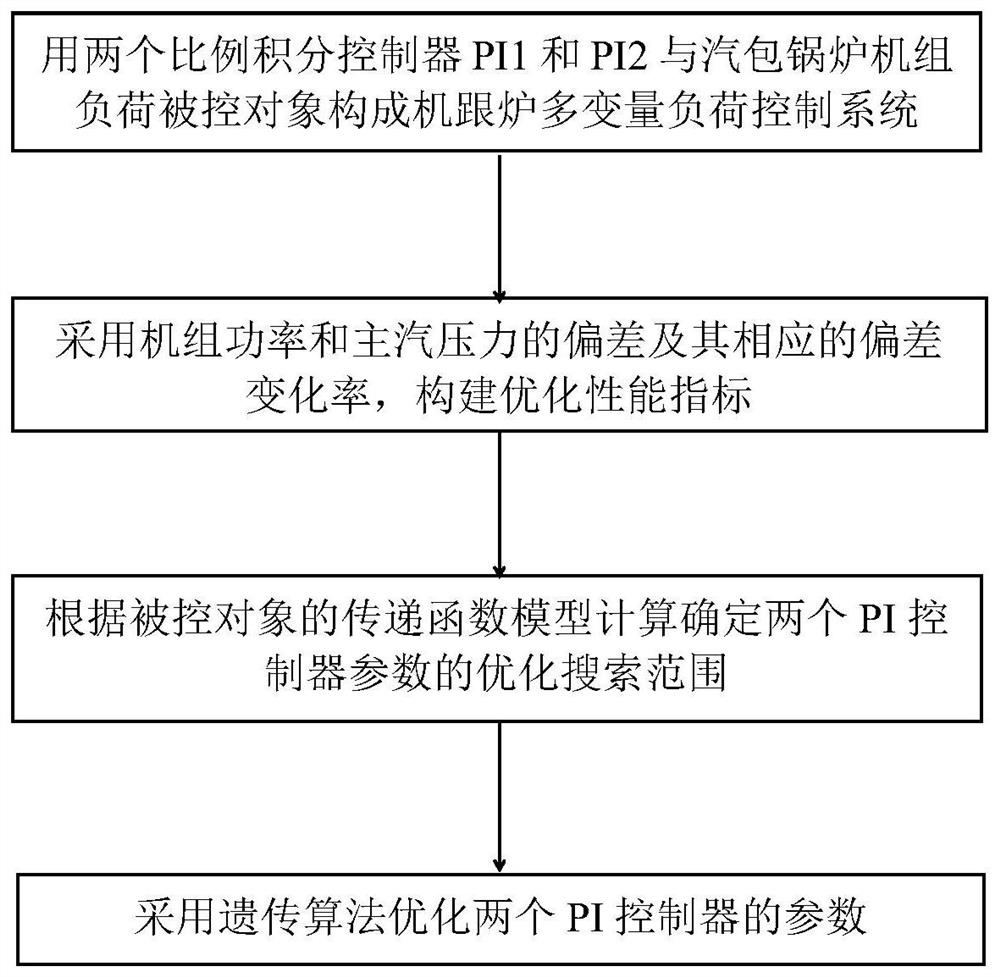

[0040] The technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings, figure 1 It is a flowchart of the present invention, and the concrete steps are as follows:

[0041] Taking the load object under 50% rated load of a drum boiler unit as the controlled object, its transfer function is:

[0042]

[0043] in:

[0044]

[0045]

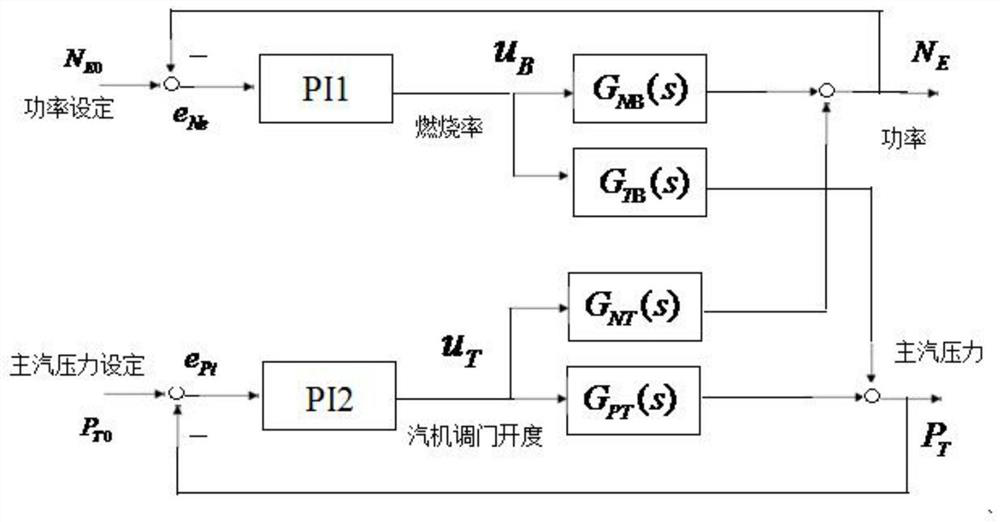

[0046] 1. Use two proportional-integral controllers PI1 and PI2 and the load controlled object of the steam drum boiler unit to form a multi-variable load control system for the boiler and boiler, such as figure 2 As shown, the input of the load controlled object of the drum boiler unit is the combustion rate u B (t) and turbine valve opening u T (t), the output is power N E (t) and main steam pressure P T (t), t is time, with u B (t) is input, N E (t) and P T (t) is the output process transfer function respectively G NB (s) and G PB (s), with u T (t) is input, N E ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com