Method for predicting fatigue life of straw throwing impeller

A technology of fatigue life prediction and fatigue life, which is applied in the field of impeller fatigue life prediction and straw throwing impeller fatigue life prediction, can solve the problems of complex interaction and difficulty in obtaining load information of throwing impeller, and achieve reasonable design, The effect of improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

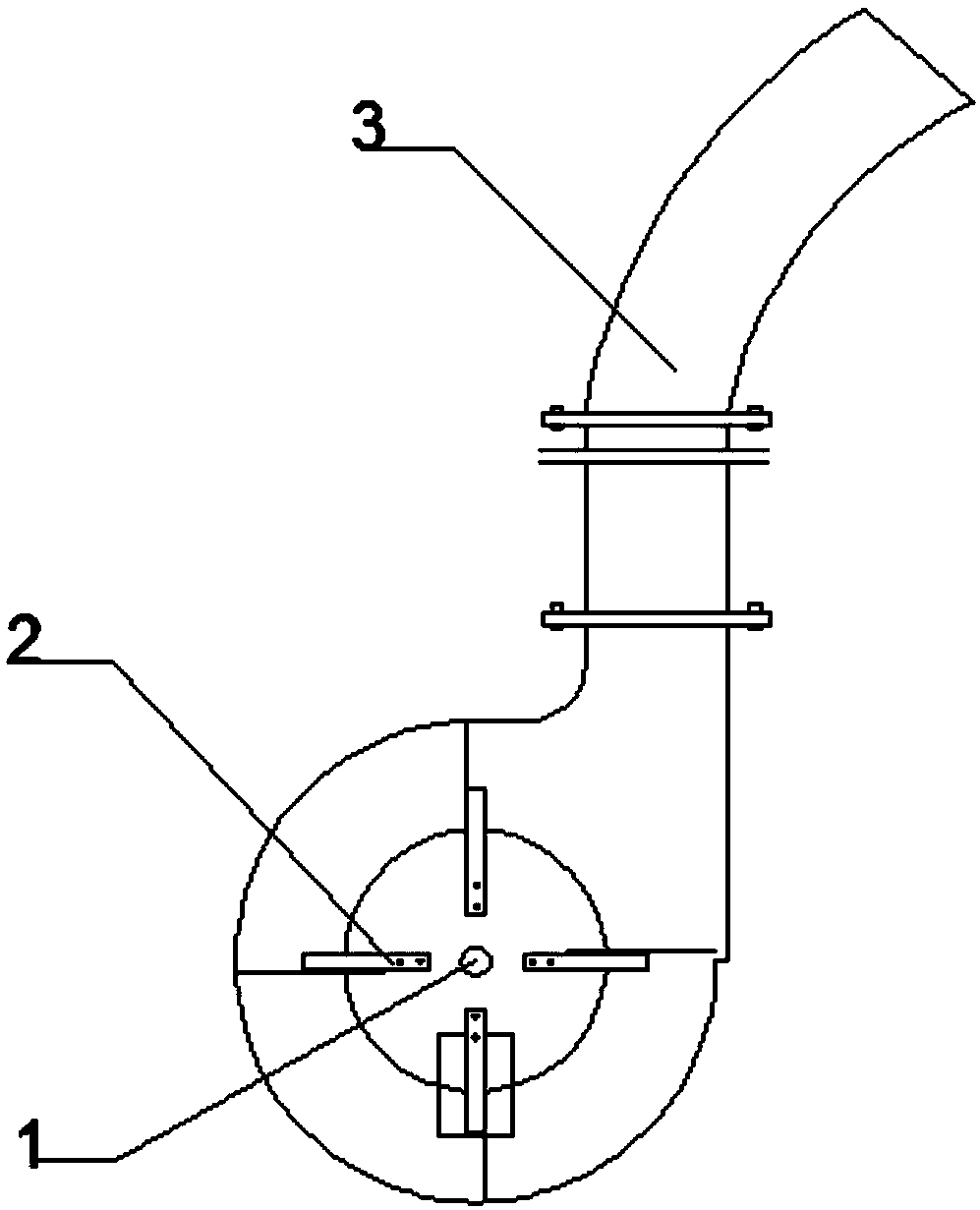

[0110] Such as figure 1 As shown, the blade-type throwing impeller device is mainly composed of a throwing impeller 1 , a throwing shell 2 and a discharge pipe 3 .

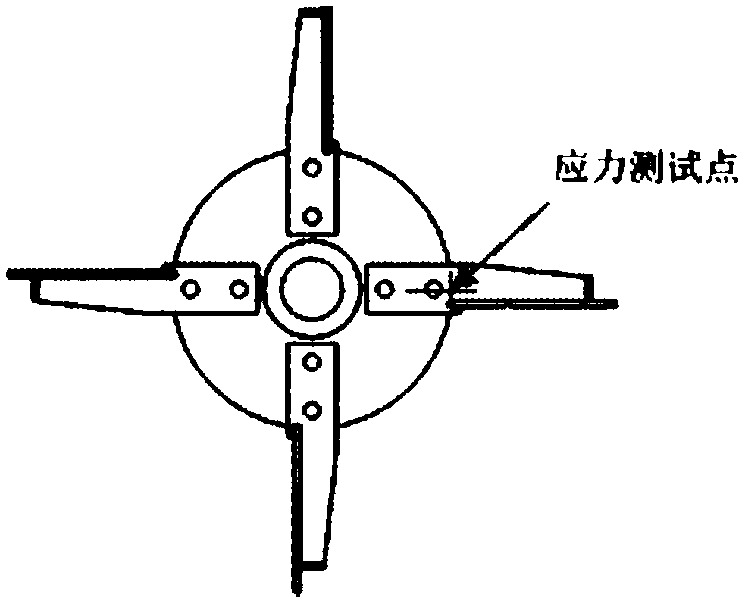

[0111] The known design conditions are: the outer diameter of the impeller of the blade throwing device is Φ500mm, the width of the blade is 140mm, the thickness of the blade is 5mm, the number of blades is 4, the inclination of the blades is radial blades, and the speed of the impeller is 1500r / min; Crushed yellow corn stalks, crushed length 4-12mm, average diameter Φ2-6mm, average density 9.21×10 -8 kg / mm 3 . The feeding amount is 0.8kg / s.

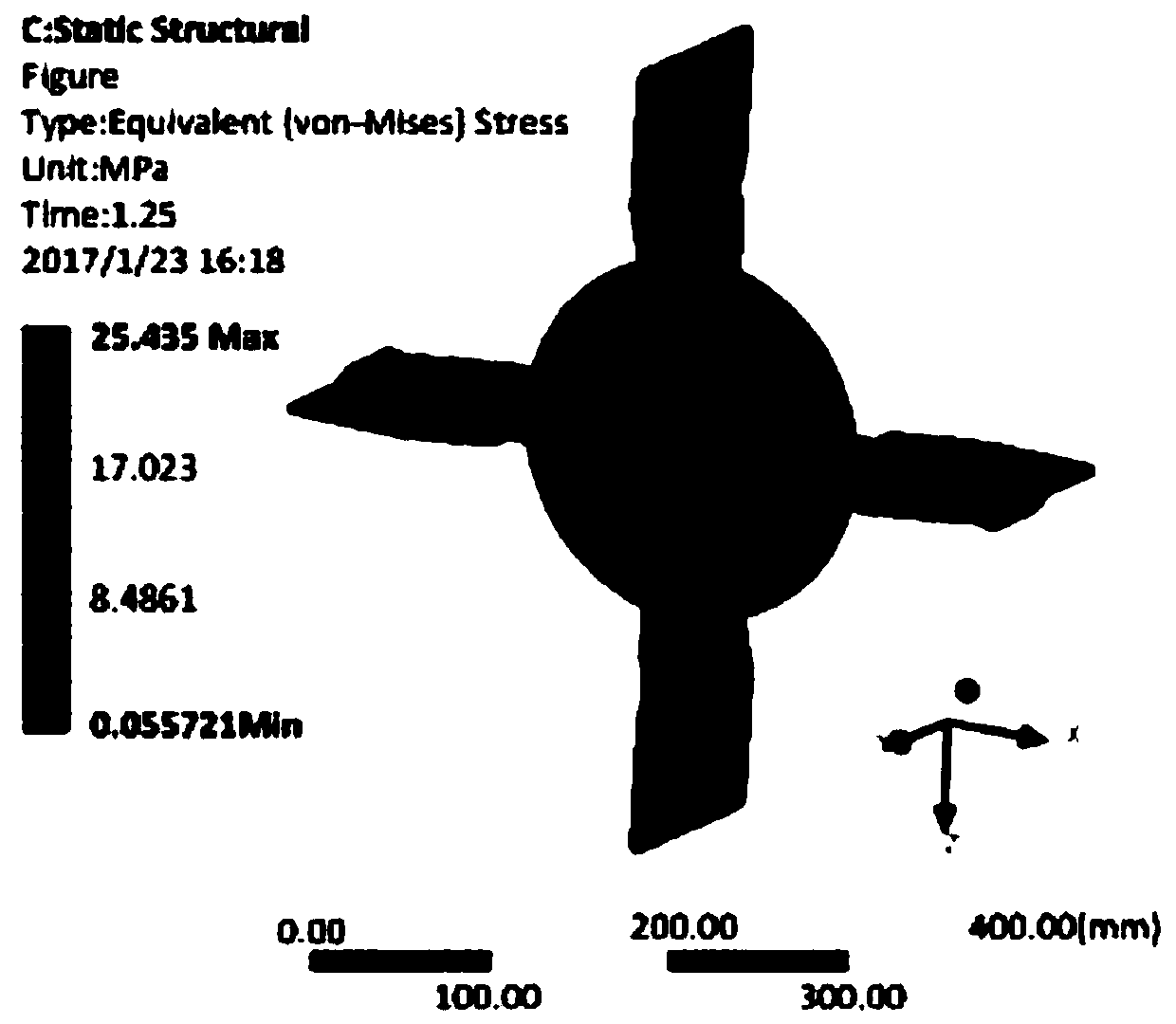

[0112] 1) The finite element model of the throwing impeller is established and meshed, in which the number of mesh elements is 26800 and the number of nodes is 40532.

[0113] The flow channel model of the vane throwing device is established in Fluent, and the calculation area is meshed, and the number of meshes is 687 533. The large eddy simulation turbulence model is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com