Multi-scale simulation method for multiphase electrohydrodynamics of core-shell structure

A technology of fluid dynamics and core-shell structure, which is applied in the field of computer simulation, can solve problems such as the calculation of the surface tension of the internal and external fluid interfaces without in-depth consideration, and achieve the effects of detailed modeling considerations, improved credibility, and accurate calculation results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] Embodiments of the present invention will be further described below in conjunction with accompanying drawings:

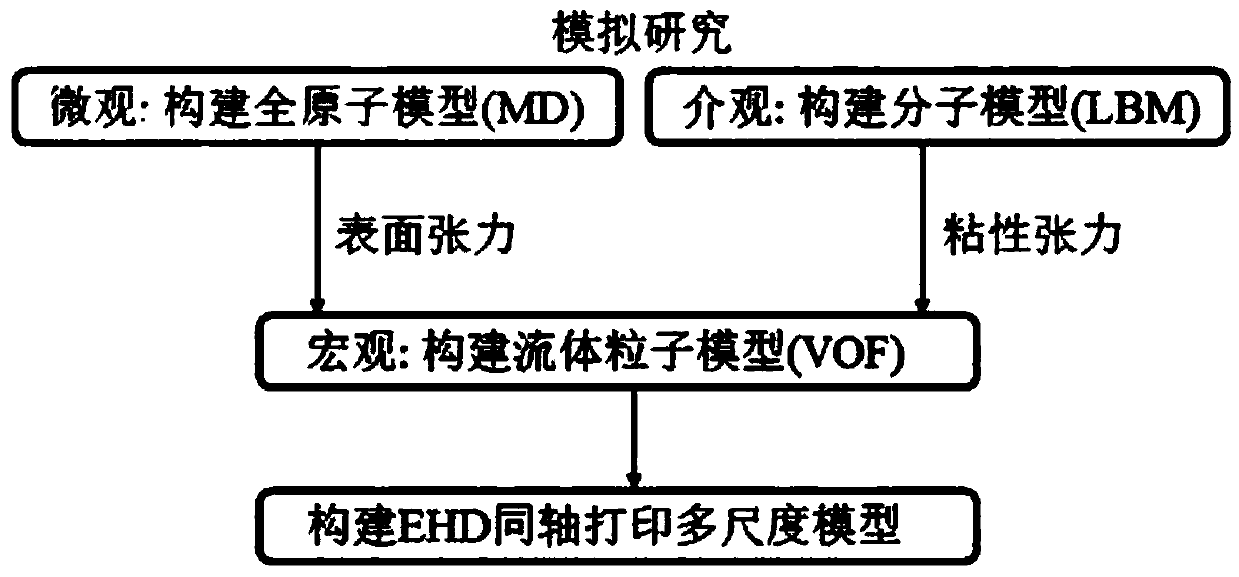

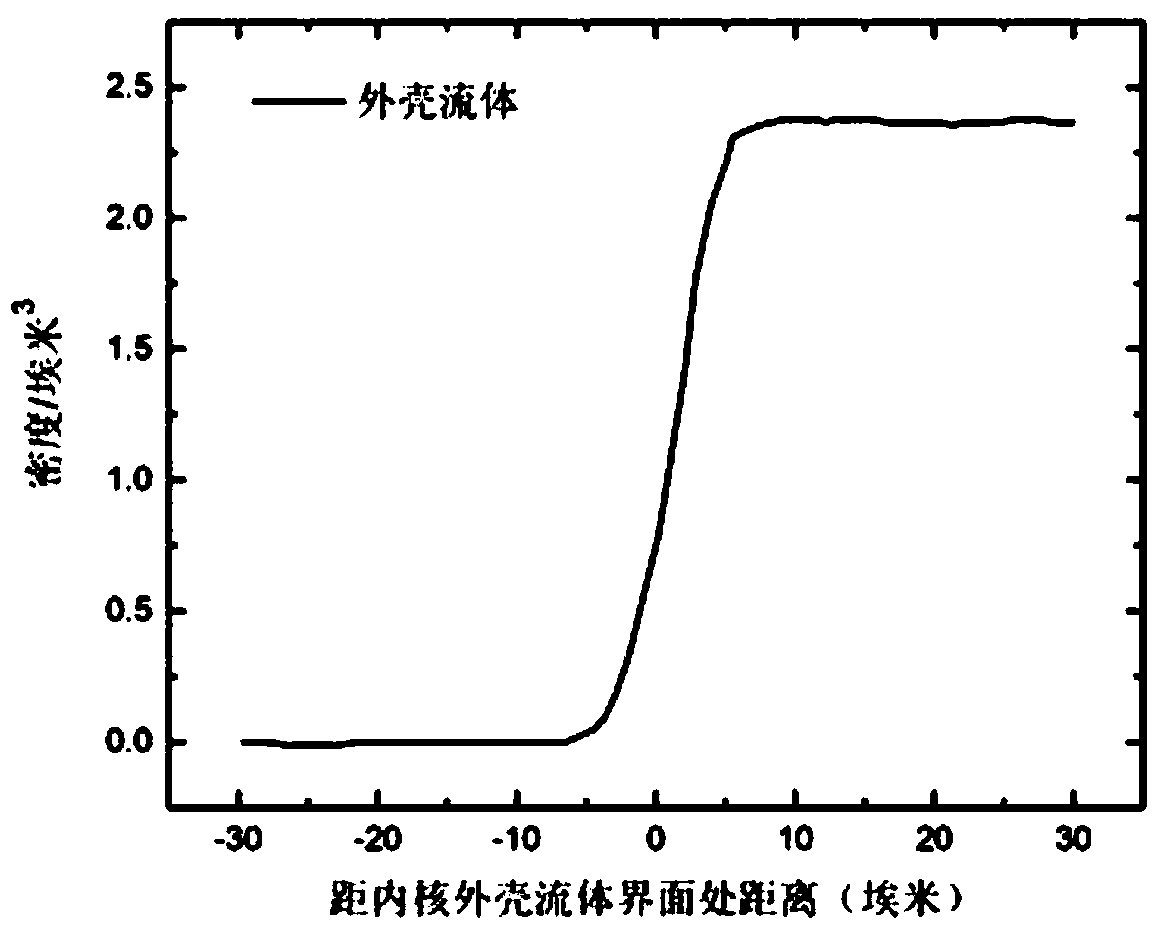

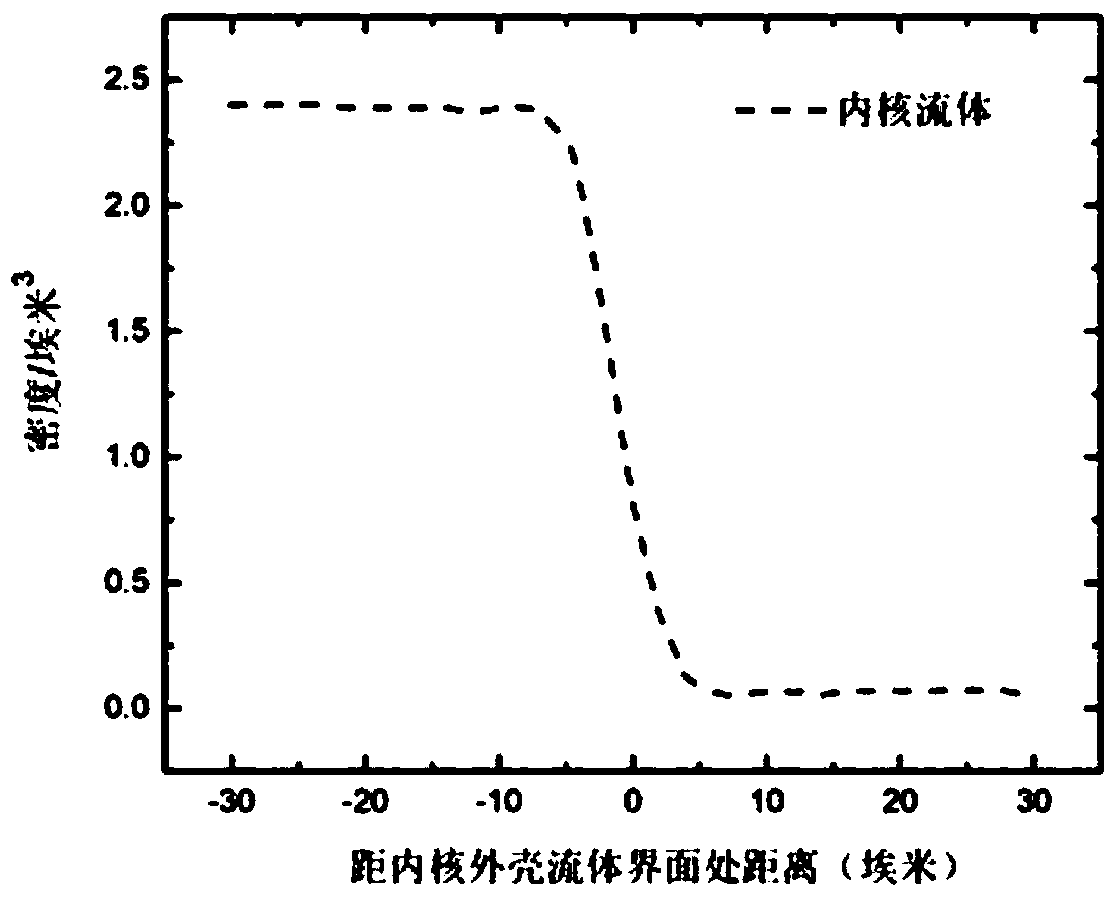

[0045] In an embodiment of the present invention, a multi-scale method for simulating multi-phase electrohydrodynamics of a core-shell structure, the multi-scale method considers the three-phase fluid, including the core and shell printing fluid and the surrounding air, and the calculations are different at the microscopic simulation scale. The tension at the fluid interface, calculate the viscous pressure tensor at the mesoscopic simulation scale, bring the interfacial tension obtained at the microscopic simulation scale and the viscous pressure tensor obtained at the mesoscopic scale to the macro scale, and calculate the current Jetting properties of body dynamics coaxial printing.

[0046] The mesoscale calculation method is based on the lattice Boltzmann method, and the process is as follows:

[0047] Calculate the viscous pressure tensor σ based on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com