Self-walking type peanut picking harvesting device

A self-propelled, harvester technology, used in excavator harvesters, harvesters, agricultural machinery and implements, etc., can solve the problems of insufficient kneading and cutting, reduced picking efficiency, and blockage of the lifting system, and achieve the separation effect. The best way to improve the cleaning efficiency and avoid the effect of blocking the harvester

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0072] In order to more clearly illustrate the embodiments of the present invention or the technical solutions in the prior art, the specific implementation manners of the present invention will be described below with reference to the accompanying drawings. Apparently, the drawings in the following description are only some embodiments of the present invention, and those skilled in the art can obtain other implementations according to these drawings without creative efforts.

[0073] It should also be noted that the left, right, up and down involved in the present invention all refer to the directions in the drawings, and the positions can be adjusted according to requirements during actual use.

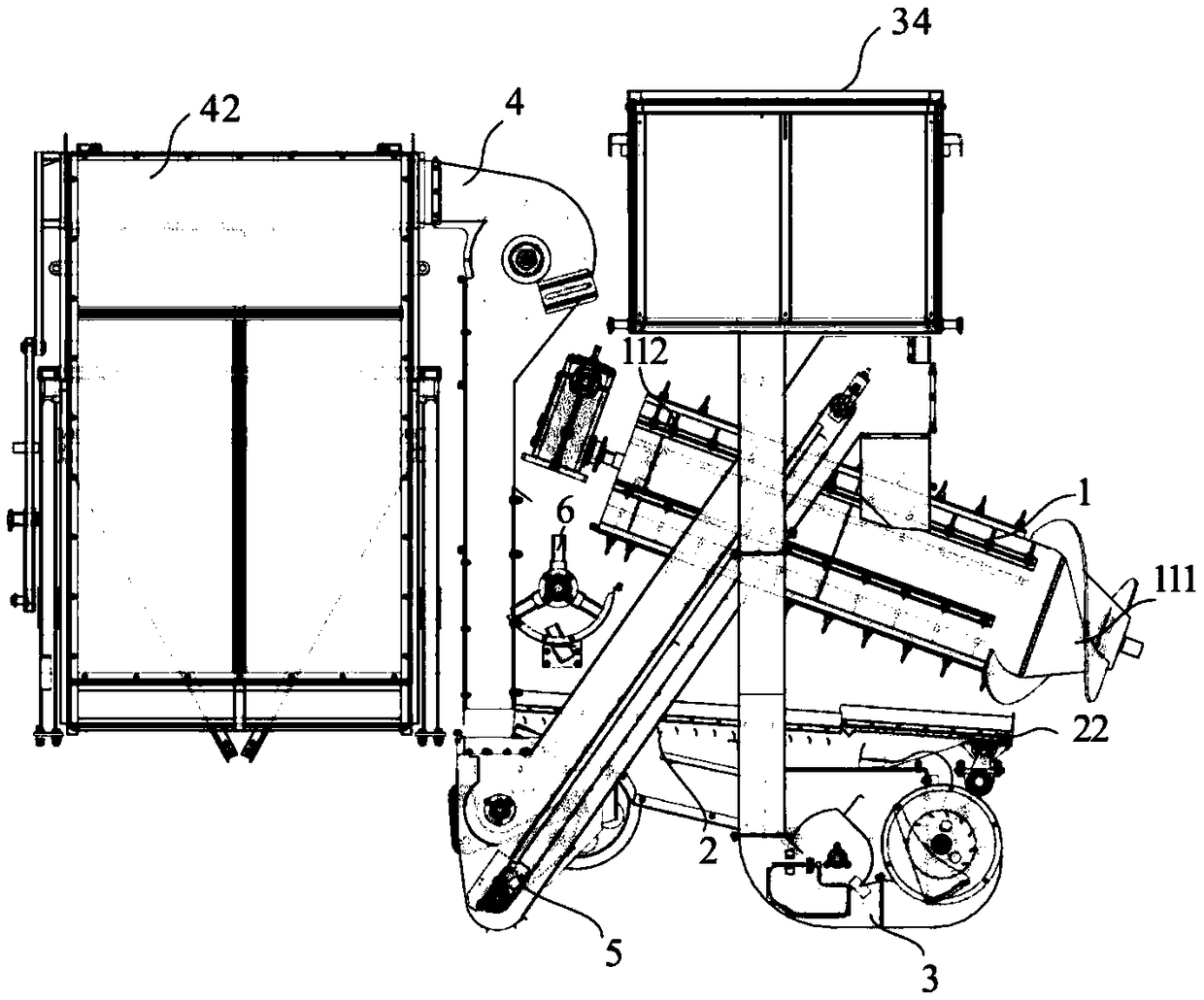

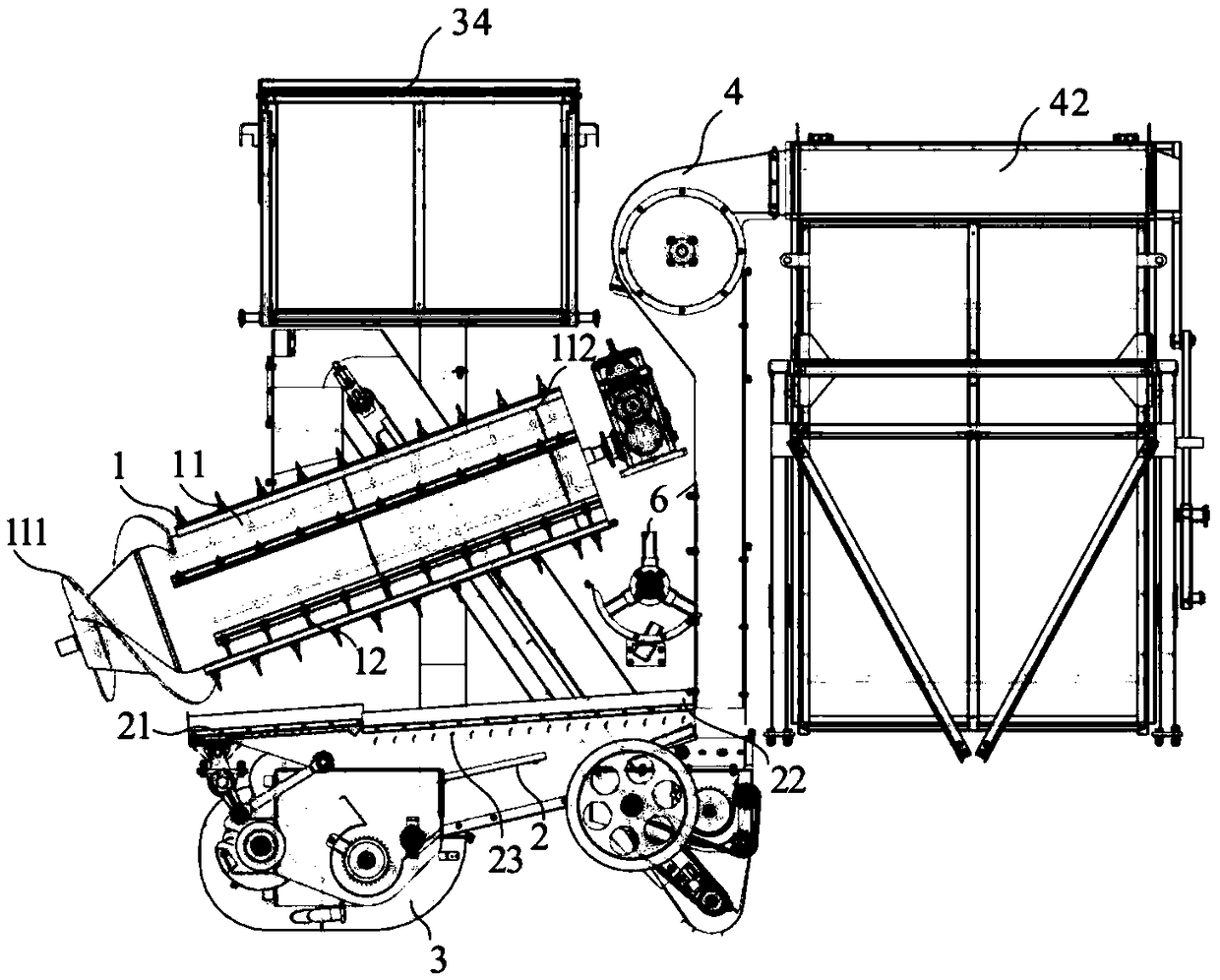

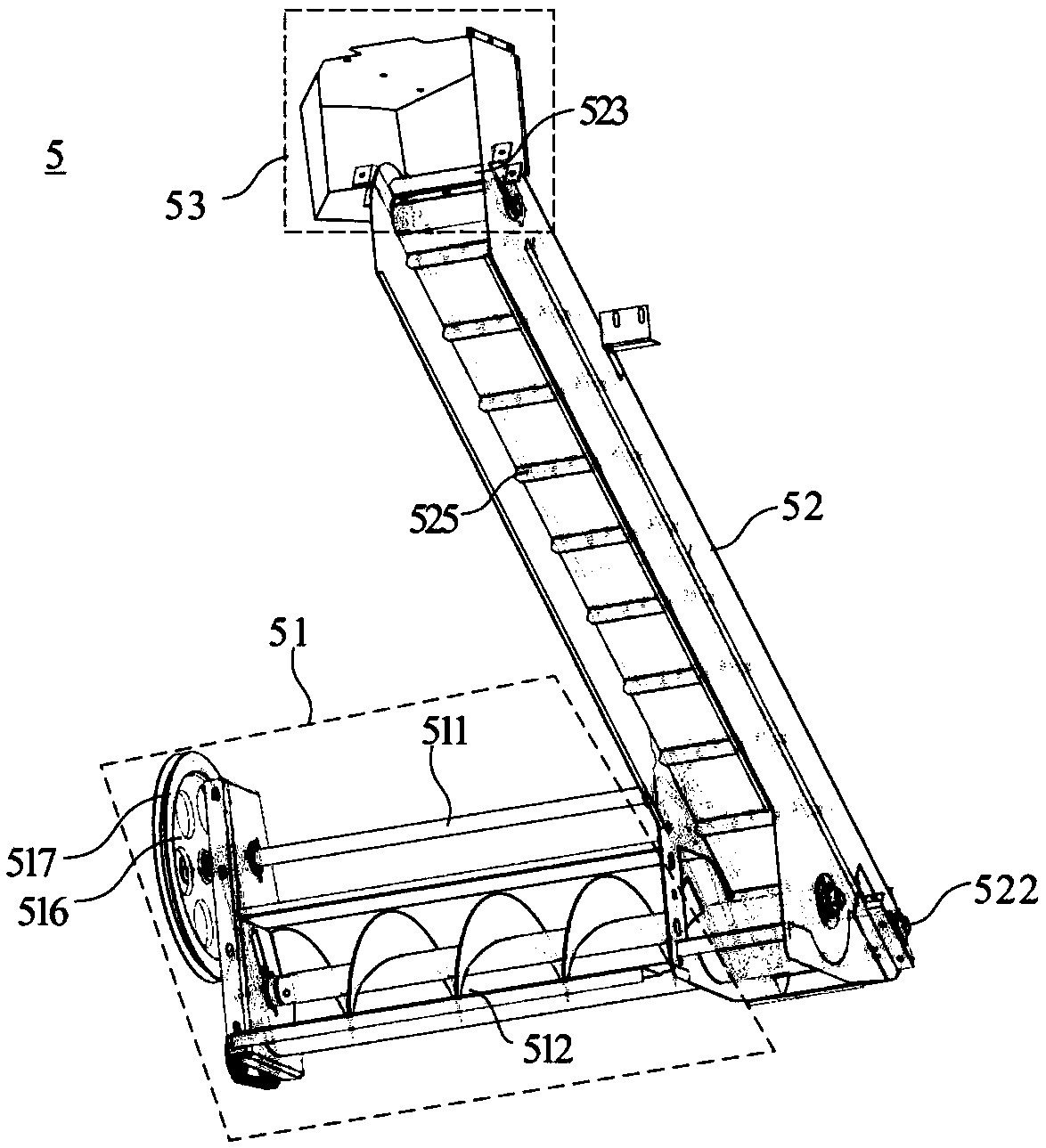

[0074] In Embodiment 1 of the present invention, see Figure 1-11 As shown, a self-propelled peanut picking and harvesting machine mainly separates the seedlings with peanuts from the peanut seedlings and peanuts, and specifically includes a fruit picking system 1, wherein the fruit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com