Sole cleaning machine with high-heeled shoe recognition unit

A technology for identifying units and cleaning soles, which is applied in the cleaning of boots and shoes, cleaning equipment, and household appliances. It can solve the problems of lack of disinfection units, complex injection mold structures, and cumbersome assembly processes, etc., and achieve good price advantages and cost performance , To prevent bacteria from invading the high cleanliness environment, the effect of simple assembly and fixed structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

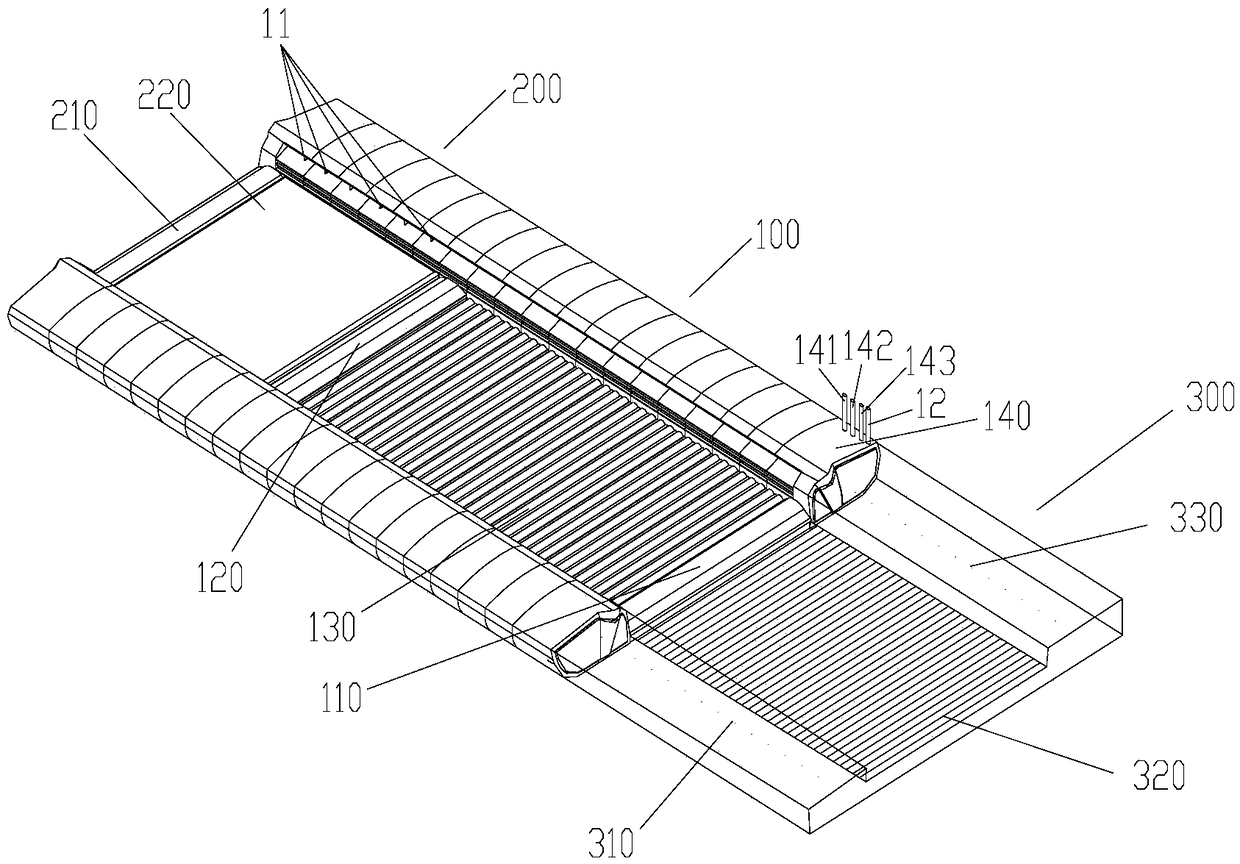

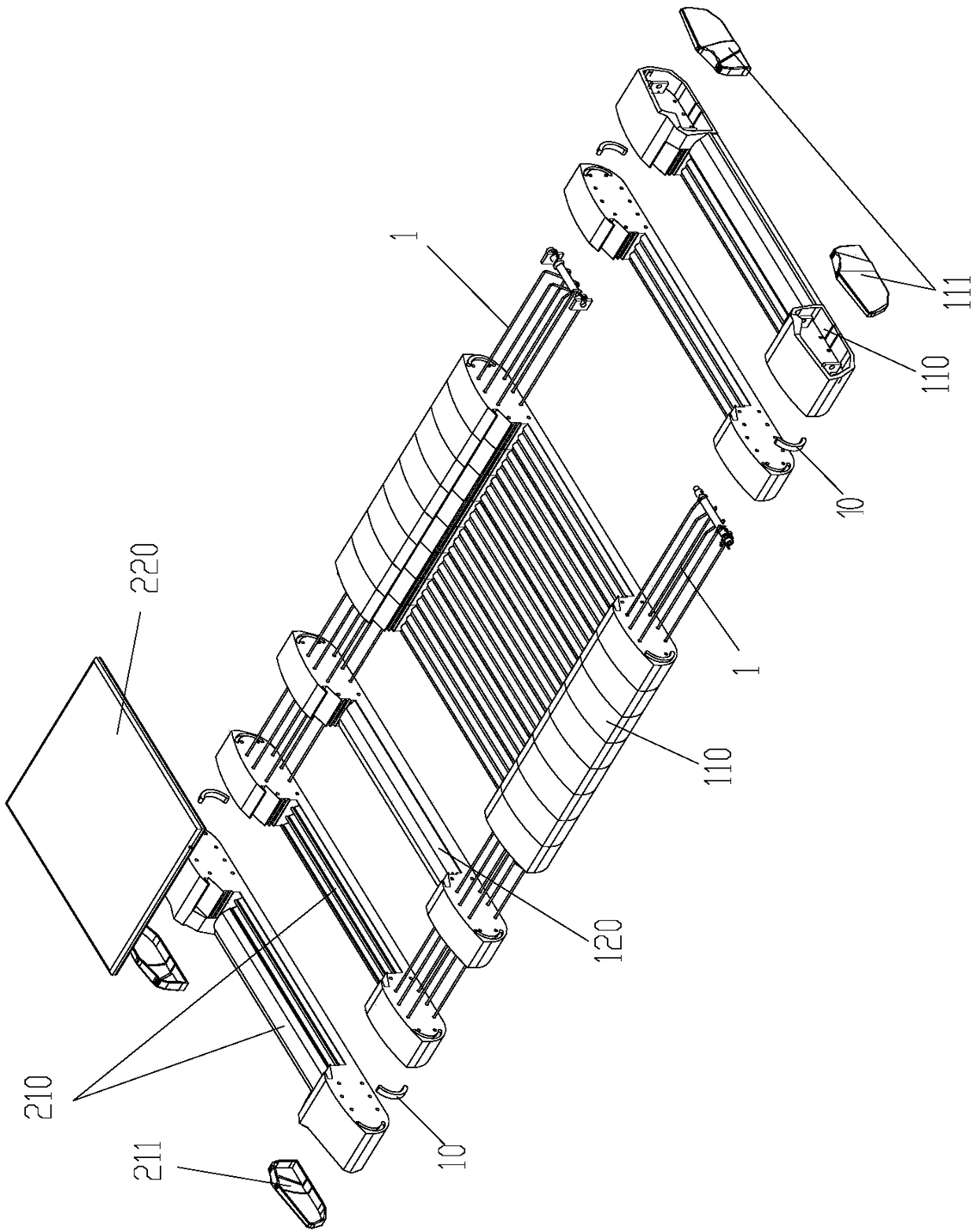

[0024] Example 1, see figure 1 , figure 2 , image 3 , Figure 4 , a shoe sole cleaning machine with a high-heeled shoe identification unit, composed of a cleaning unit 100, a disinfection unit, a drying unit 200 and a high-heeled shoe identification unit 300 assembled and connected; the cleaning unit 100 is composed of a plurality of cleaning segments, and each cleaning segment includes The cleaning skeleton segment 110 and the cleaning member 130 arranged on the cleaning skeleton segment; the drying unit 200 is composed of a drying skeleton and an absorbent pad 220, and the drying skeleton is composed of a plurality of drying skeleton segments 210; the cleaning skeleton segment 110 and The outer contours of the assembled joint surfaces of the drying skeleton segments 210 have the same shape, and the assembled joint surfaces constitute the corresponding side outer contour surfaces of the corresponding segments; all the skeleton segments are fixedly connected into one body ...

Embodiment 2

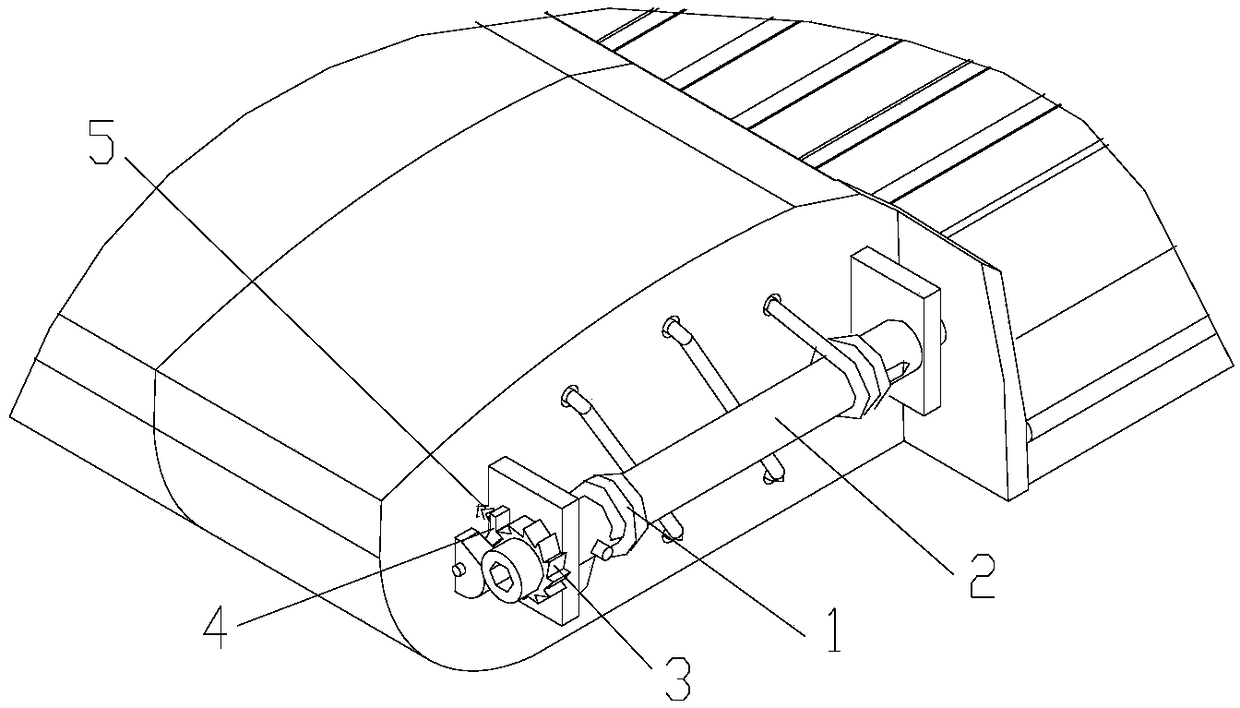

[0031] Example 2, see Figure 5 , The twisted shaft 2 forms a one-way rotation structure through an overrunning clutch structure. The overrunning clutch structure includes a mandrel composed of a twisted shaft 2, on which an outer ring 6 is sleeved, and the outer ring 6 is rotatably arranged on the corresponding frame segment, and the corresponding frame segment is provided with a The locking screw 8 of the outer ring 6; the outer ring 6 is provided with a rolling body 9 through the receiving groove, and the rolling body 9 is in contact with the first spring 7, the first spring 7 is installed on the outer ring 6, and the first spring 7 is Push the rolling body 9 to one end of the receiving groove so that when the mandrel rotates in the set direction, the mandrel maintains the position of the rolling body 9 through friction, and the mandrel forms a combined state with the outer ring 6 through the rolling body 9; When the mandrel rotates in the opposite direction to the set dir...

Embodiment 3

[0033] Example 3, see Image 6 , the disinfection unit 400 is located between the cleaning unit 100 and the drying unit 200, the disinfection unit is composed of a plurality of disinfection skeleton segments; between the cleaning unit 100 and the disinfection unit 400, and between the disinfection unit 400 and the drying unit 200 All are connected through the corresponding transition frame 120; the disinfection unit is provided with one of the disinfectant spray head 11, the disinfectant pool 401 and the disinfectant adsorption pad, or a combination of any two, or three combinations; the disinfectant spray The head 11 is distributed on both sides of the disinfection unit, the disinfectant pool 401 or the disinfectant adsorption pad, and the disinfectant spray head 11 are respectively connected to the disinfectant liquid supply interface 12 through the pipeline, and the disinfectant liquid supply interface 12 is integrated in the external connection of the cleaning unit 100 On ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com