Modified silicon carbide powder and preparation method thereof

A silicon carbide powder and modification technology, which is applied in the direction of silicon carbide, carbide, grain processing, etc., can solve the problems of material plasticity improvement, local stress concentration, local work hardening, etc., and achieve small container wear, low material pollution, and low cost. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

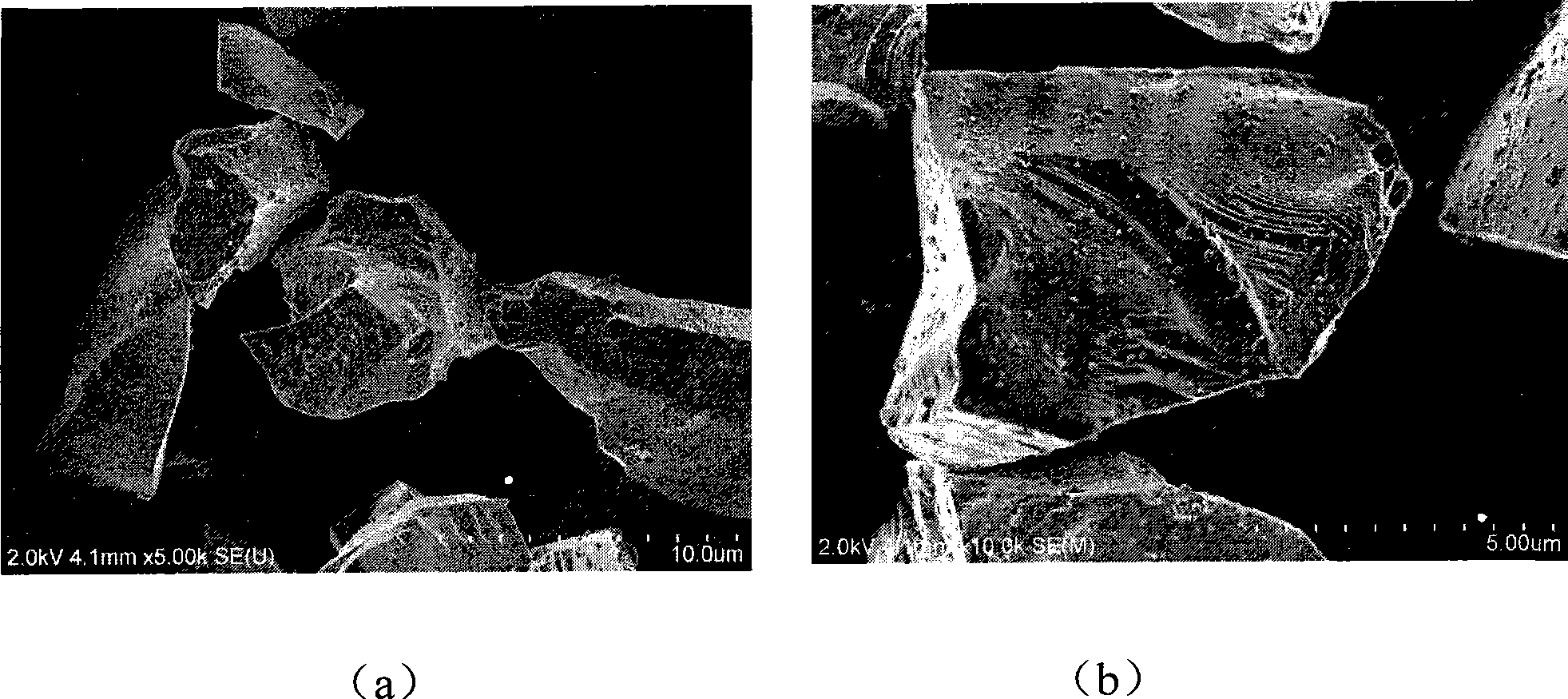

[0027] The silicon carbide powder material that present embodiment handles, its silicon carbide particle is such as figure 1 (a), figure 1 The irregular shape of (b) (S-4800 field emission scanning electron microscope, the powder sample is spread on the conductive glue, respectively magnified by 5000 times and 10000 times), and the volume average particle size is 7.4 μm.

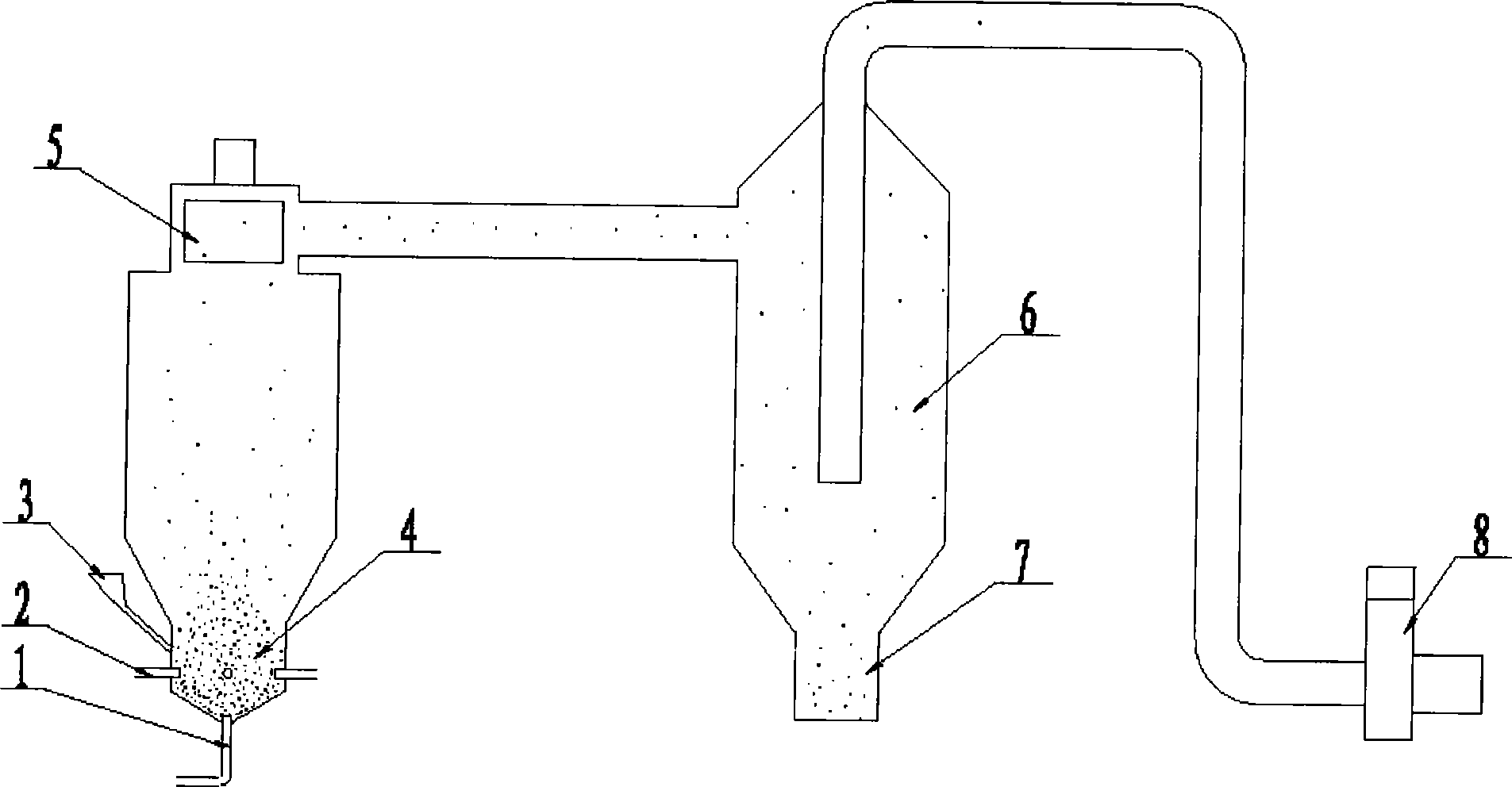

[0028] Its preparation method is to use image 3 The silicon carbide powder modification treatment device shown includes a cylindrical grinding chamber 4 with a conical bottom, a classification wheel 5, a cyclone dust collector 6, an induced draft fan 8, and a hopper 3, and the hopper 3 is located at the cylindrical grinding chamber with a conical bottom. In the lower part of the chamber 4, silicon carbide powder to be processed is introduced into the conical-bottomed cylindrical grinding chamber 4; the lower part of the conical-bottomed cylindrical grinding chamber 4 is provided with a bottom nozzle 1 to p...

Embodiment 2

[0032] The silicon carbide powder material that present embodiment handles, its silicon carbide particle is such as figure 1 The irregular shape of (a) and (b) (S-4800 field emission scanning electron microscope, the powder sample is spread on the conductive glue, the magnifications are 5000 times and 10000 times respectively), and the volume average particle size is 7.4 μm.

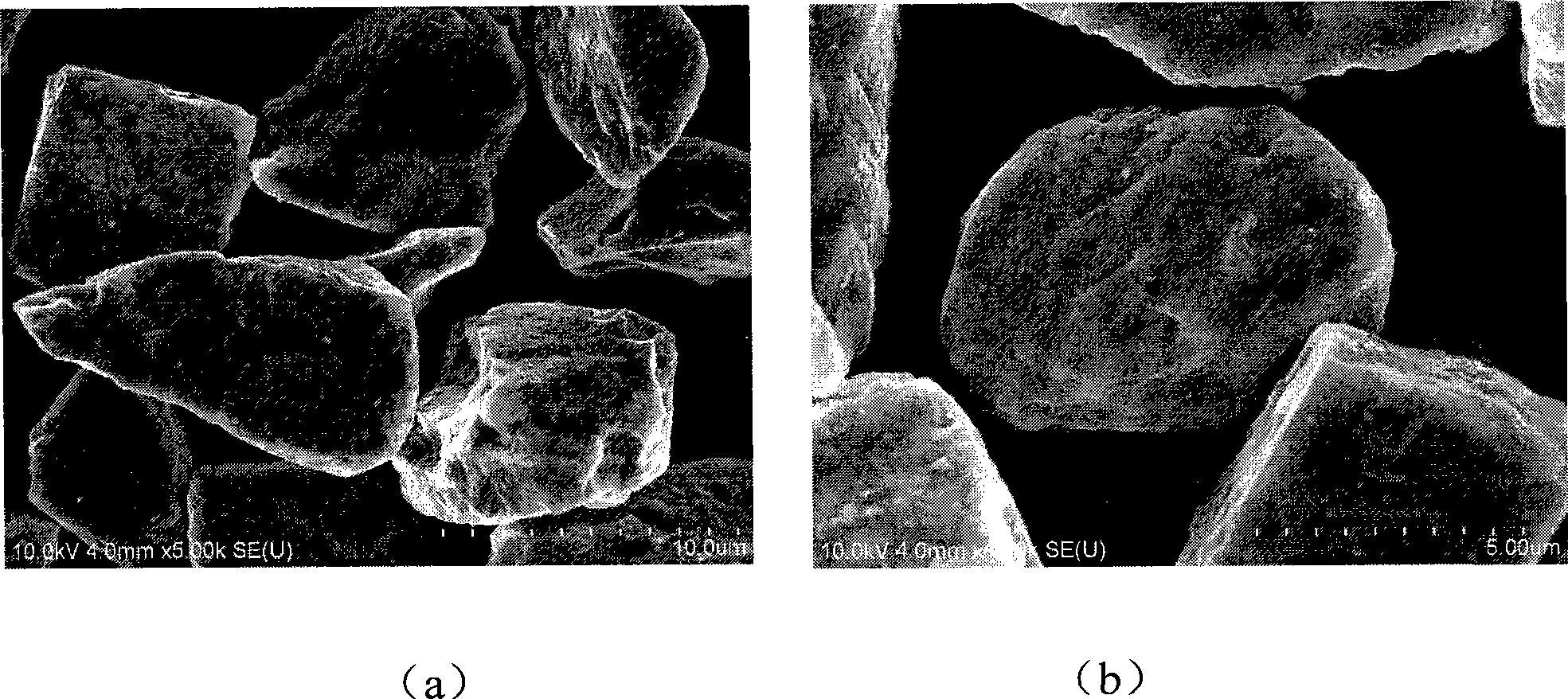

[0033] Its preparation method is to use image 3 In the silicon carbide powder modification treatment device shown, turn on the induced draft fan 8, introduce 5kg of silicon carbide into the cylindrical grinding chamber 4 at the bottom of the cone, open the bottom nozzle 1, pass in 0.01MPa dry and purified compressed air, and then open four levels Cloth the two of the spray nozzles 2, pass through 0.2MPa dry and purified compressed air, grind for 1 hour, then increase the pressure to 0.4MPa, continue grinding for 2 hours, the treatment effect can be seen Figure 4 (a), (b).

[0034] and figure 2 Same...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com