A kind of extraction method of artificial forest bark saponins active components

An active ingredient and extraction method technology, which is applied in the field of extraction of plantation bark saponins active ingredients, can solve the problems of low utilization rate and low extraction rate of active substances, and achieves promoting pulverization and emulsification, improving extraction rate and yield. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

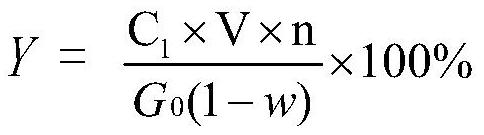

Image

Examples

Embodiment 1

[0028] Extraction of Total Saponins from Black Wattle Bark

[0029] Take 3 parts of 3g (accurate to 0.001) black wattle bark powder raw material in 100mL Erlenmeyer flask, add 0.5mg / mL cellulose complex enzyme 50% ethanol solution at a ratio of 1:10, and ultrasonically treat at 50°C for 40min (ultrasonic frequency 40KHz, ultrasonic power 120W), filter, transfer the filtrate to a 100mL volumetric flask, and set the volume to 100mL.

Embodiment 2

[0037] Extraction of Total Saponins from the Bark of Acacia

[0038] Take 3 parts of 3g (accurate to 0.001) bark powder raw material of Acacia acacia respectively in 100mL Erlenmeyer flask, add 0.5mg / mL cellulose compound enzyme 50% ethanol solution with the ratio of material to liquid 1:10, at 50 ℃ Sonicate for 40 minutes (ultrasonic frequency 40KHz, ultrasonic power 140W), filter, transfer the filtrate to a 100mL volumetric flask, and dilute to 100mL.

Embodiment 3

[0045] Extraction of Total Saponins from Yew Bark

[0046] Take 3 parts of 3g (accurate to 0.001) yew bark powder raw material in 100mL Erlenmeyer flask, add 0.5mg / mL cellulose complex enzyme 50% ethanol solution at a material-to-liquid ratio of 1:10, and ultrasonically treat at 50°C After 40 minutes (ultrasonic frequency 40KHz, ultrasonic power 160W), filter, transfer the filtrate to a 100mL volumetric flask, and dilute to 100mL.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com