Preparation of CD@NH2-UiO-66/g-C3N4 composite material and hydrogen production from photocatalytic water splitting

A technology of nh2-uio-66 and composite materials, which is applied in the fields of hydrogen, hydrogen production, chemical/physical processes, etc., can solve the problem of low hydrogen production efficiency from photo-splitting water, and achieve the effect of improving the performance of photo-splitting water for hydrogen production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

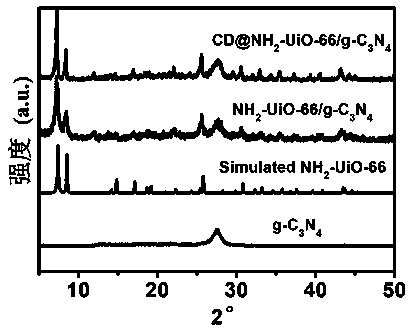

[0022] Specific implementation mode 1: a kind of CD@NH in this implementation mode 2 -UiO-66 / g-C 3 N 4 The preparation of the composite material is done in the following steps:

[0023] 1. g-C 3 N 4 preparation of

[0024] 2. NH 2 -UiO-66 / g-C 3 N 4 Preparation of composite materials: ZrCl 4 and 2-aminoterephthalic acid in a mixed solution of N,N,-dimethylformamide (DMF) and hydrochloric acid, and ultrasonically treated at an ultrasonic frequency of 35~45 KHz for 20~30 min, until fully dissolved After adding g-C 3 N 4 , the obtained mixed solution was placed in a hydrothermal reaction kettle and heated at 120 °C for 24 h, the product was filtered and washed three times with DMF / methanol, and then dried;

[0025] NH mentioned in step 2 2 -UiO-66 with g-C 3 N 4 The mass ratio is 5: 1;

[0026] DMF described in step 2 and hydrochloric acid volume ratio 5: 1;

[0027] 3. CD@NH 2 -UiO-66 / g-C 3 N 4 Preparation of composite materials: the above synthesized NH 2 -Ui...

specific Embodiment approach 2

[0031] Embodiment 2: This embodiment differs from Embodiment 1 in that the glucose concentration described in Step 3 is 5 mmol / L, and other steps and parameters are the same as Embodiment 1.

specific Embodiment approach 3

[0032] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the glucose concentration in Step 3 is 20 mmol / L, and other steps and parameters are the same as Embodiment 1 or 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com