a kind of ni(oh) 2 Preparation method of /tppa-2 material and hydrogen production by photolysis of water

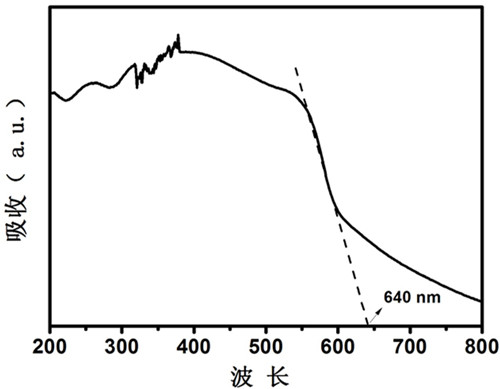

A tppa-2, raw material technology, which is applied in the field of photocatalytic hydrolysis for hydrogen production, can solve the problem of low hydrogen production efficiency of photo-splitting water, and achieve the effect of improving the performance of photo-splitting water for hydrogen production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0011] Embodiment 1: a kind of Ni(OH) of the present embodiment 2 The preparation of / TpPa-2 material is accomplished in the following steps:

[0012] Step 1. Preparation of TpPa-2: Add 1,3,5-trialdehyde phloroglucinol (0.063 g) and 2,5-dimethyl-p-phenylenediamine (0.048 g) into a heat-resistant glass tube, Then a mixed solution of 1,3,5-trimethylbenzene (1.5 mL), 1,4-dioxane (1.5 mL) and acetic acid (0.5 mL, 3 mol / L) was added, and the ultrasonic frequency was 40 kHz Sonicate for 30 min under the same conditions, perform three freeze-thaw cycle degassing in a liquid nitrogen bath, heat at 120 °C for 72 h after sealing, filter and wash with tetrahydrofuran three times, and dry in a vacuum oven at 180 °C for 24 h;

[0013] Step 2, Ni(OH) 2 / TpPa-2 material preparation: Disperse TpPa-2 in 30mL 0.25 mol / L NaOH solution, sonicate for 20-30 min at an ultrasonic frequency of 35-45 kHz, add 42 µL Ni(NO 3 ) 2 The solution was treated under the condition of magnetic stirring for 6 ...

Embodiment 2

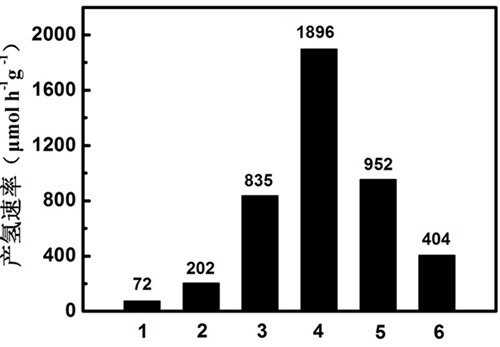

[0014] Embodiment 2: the difference between this embodiment and embodiment 1 is: the Ni(NO 3 ) 2 The volume is 83 µL, and other steps and parameters are the same as in Example 1. Obtain (1 mol%) Ni(OH) 2 / TpPa-2 material.

Embodiment 3

[0015] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is: the Ni(NO 3 ) 2 The volume is 208 µL, and other steps and parameters are the same as those in Example 1 or 2. Obtain (2.5mol%) Ni(OH) 2 / TpPa-2 material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com