Preparation of alpha-Fe2O3/TpPa-2 composite and application of alpha-Fe2O3/TpPa-2 composite in water photolysis for hydrogen production

A composite material, tppa-2 technology, applied in the direction of organic compound/hydride/coordination complex catalyst, hydrogen/synthesis gas production, hydrogen, etc., can solve the problem of low efficiency of hydrogen production by photolysis of water, and improve the efficiency of light The effect of water splitting hydrogen production performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

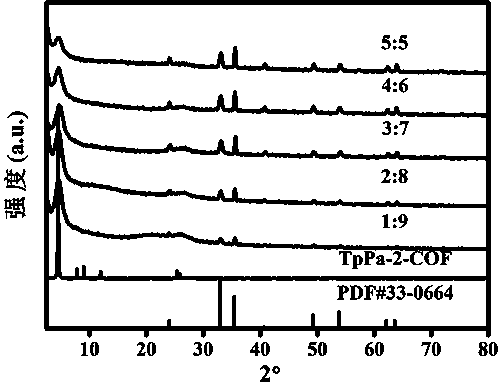

[0021] Example 1: A kind of α-Fe of this embodiment 2 o 3 The preparation of / TpPa-2 material is accomplished in the following steps:

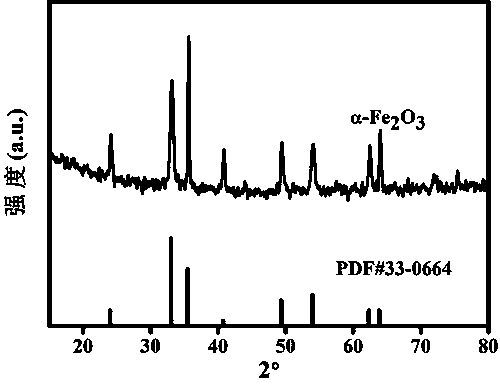

[0022] Step 1, α-Fe 2 o 3 preparation of

[0023] Step 2, α-Fe 2 o 3 / TpPa-2 composite material preparation: α-Fe 2 o 3 (3.8mg), 1,3,5-trialdehyde phloroglucinol (0.021g) and 2,5-dimethyl-p-phenylenediamine (0.020g) were added into a heat-resistant glass tube, followed by 1,3, 5-trimethylbenzene (1.5mL), 1,4-dioxane (1.5mL) and acetic acid (0.5mL, 3mol·L -1 ) mixed solution, ultrasonically treated for 30min at an ultrasonic frequency of 40KHz, degassed by three freeze-thaw cycles in a liquid nitrogen bath, sealed and heated at 120°C for 72h, filtered and washed several times with tetrahydrofuran, and dried to obtain α -Fe 2 o 3 / TpPa-2 (mass ratio 1:9) composite material;

Embodiment 2

[0024] Example 2: The difference between this embodiment and Example 1 is that the α-Fe described in step 2 2 o 3 The quality of is 8.5mg, and other steps and parameter are identical with embodiment 1. get α-Fe 2 o 3 / TpPa-2 (mass ratio is 2:8) composite material;

Embodiment 3

[0025] Example 3: The difference between this embodiment and Example 1 or 2 is: the α-Fe described in step 2 2 o 3 The quality of is 14.6mg, and other steps and parameter are identical with embodiment 1 or 2. get α-Fe 2 o 3 / TpPa-2 (mass ratio is 3:7) composite material;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com