Preparation method and water photolysis hydrogen production application of covalently bonded titanium dioxide@TpPa-1 composite material

A composite material, covalent bond technology, applied in the direction of organic compound/hydride/coordination complex catalyst, hydrogen, inorganic chemistry, etc. The effect of hydrogen performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

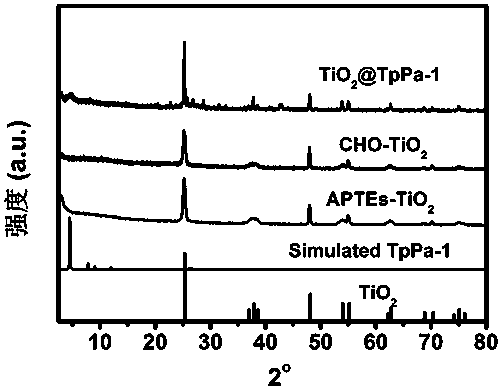

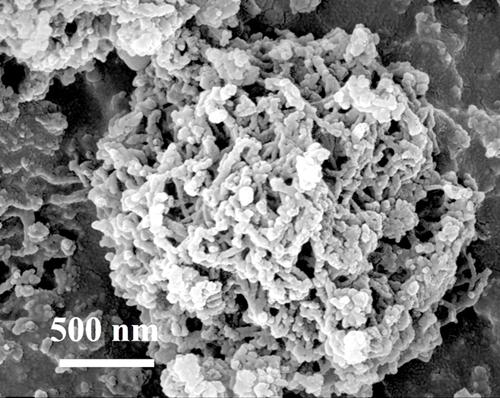

[0025] Specific embodiment one: a kind of TiO of this embodiment 2 The preparation of the @TpPa-1 composite was done as follows:

[0026] 1. Amino modified TiO 2 (APTEs-TiO 2 ) preparation;

[0027] 2. Aldehyde titanium dioxide (CHO-TiO 2 ) preparation: the APTEs-TiO 2 Place it in dioxane, and ultrasonically treat it for 10 minutes under the condition of ultrasonic frequency of 35-45KHz. After fully mixing, add trialdehyde phloroglucinol (Tp) and acetic acid aqueous solution, and place the obtained mixed solution in heat-resistant glass tube, and vacuum stirred at 115-125°C for 6h, the product was filtered and washed three times with tetrahydrofuran, and dried to obtain CHO-TiO 2 ;

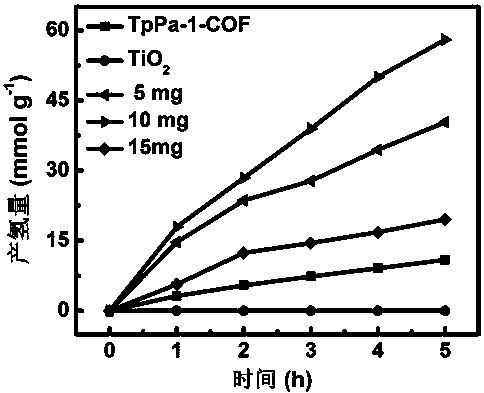

[0028] 3. TiO linked by covalent bonds 2 Preparation of @TpPa-1 composites: Tp and p-phenylenediamine were mixed with different masses of the above-synthesized CHO-TiO 2 The material is placed in a mixed solution of dioxane solution and mesitylene, and ultrasonically treated for 30 minutes...

specific Embodiment approach 2

[0036] Specific embodiment two: the difference between this embodiment and specific embodiment one is: the CHO-TiO described in step three 2 The amount of addition is 10mg, and other steps and parameters are the same as in Embodiment 1.

specific Embodiment approach 3

[0037] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is: the CHO-TiO described in step three 2 The added amount is 15 mg, and other steps and parameters are the same as those in Embodiment 1 or 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com