Color steel tile roof photovoltaic array operation and maintenance robot support system

A photovoltaic array and support system technology, applied in the field of operation and maintenance, can solve high-risk problems, achieve low center of gravity, stable operation, and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

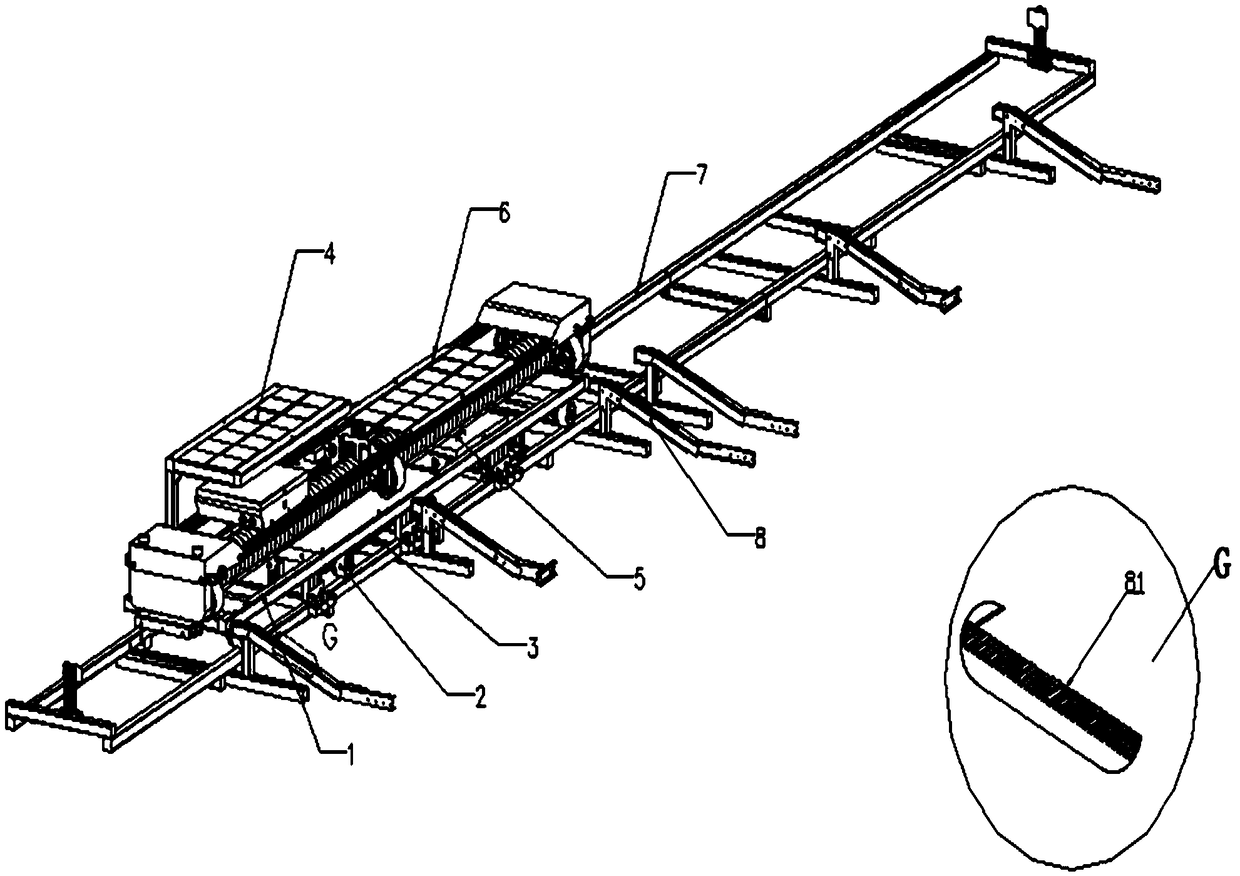

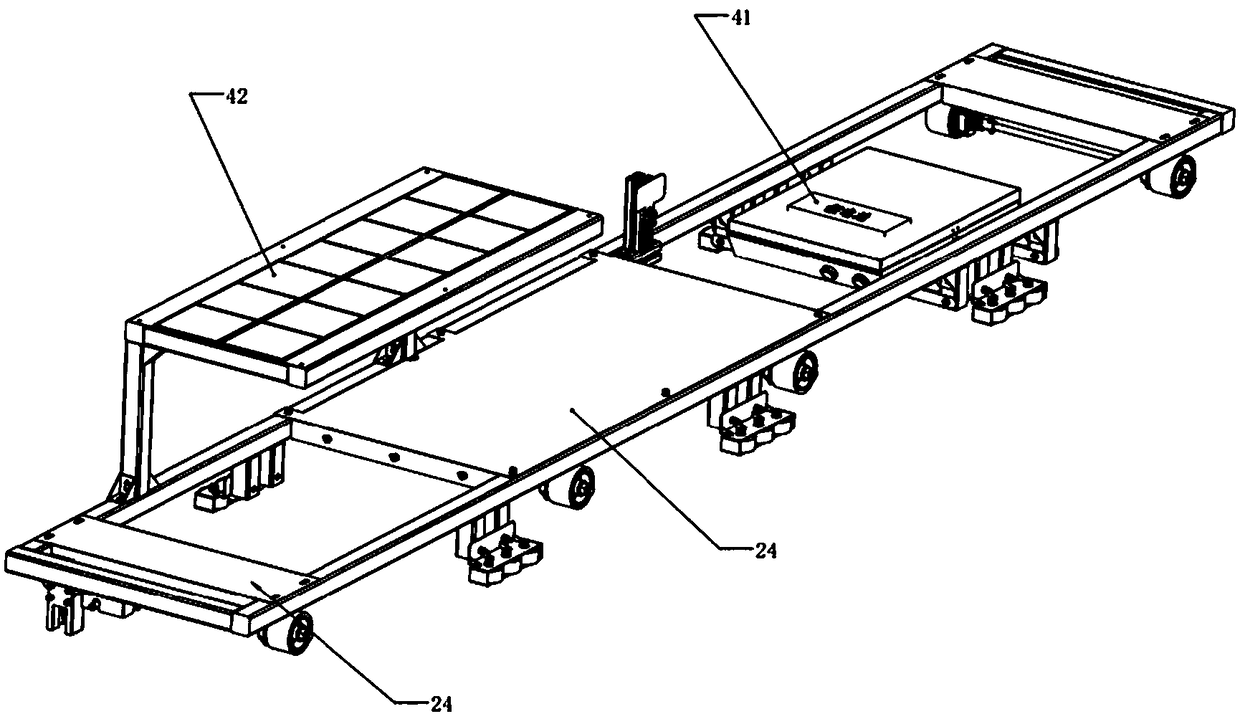

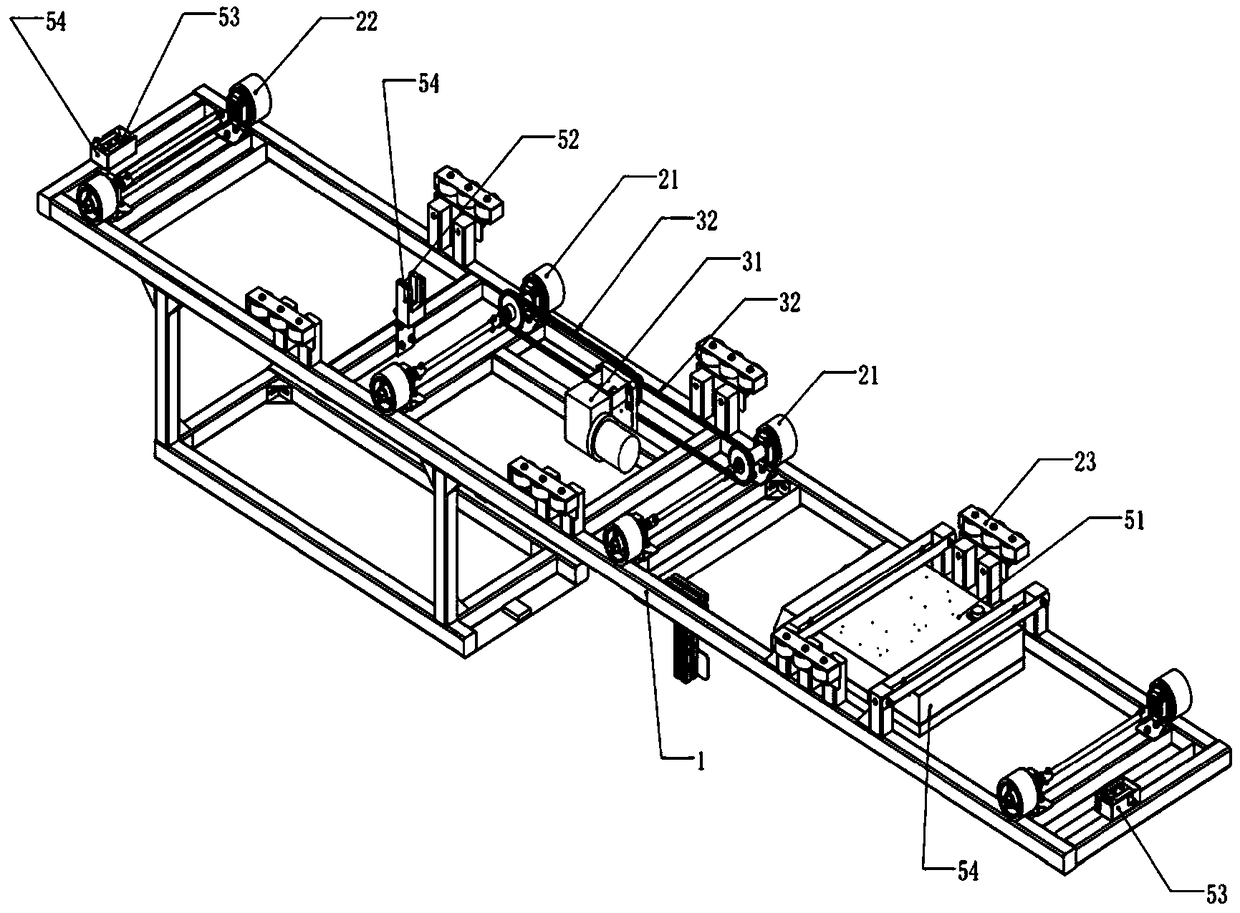

[0031] Example: such as figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 As shown, a color steel tile roof photovoltaic array operation and maintenance robot support system of the present invention includes: ferry car 1, ferry car frame 11, walking mechanism 2, driving mechanism 3, self-power supply system 4, control system 5, photovoltaic operation and maintenance Cleaning robot 6, track 7, bridge 8 and anti-skid structure 81, wherein:

[0032] The traveling mechanism 2, the driving mechanism 3, the self-power supply system 4, and the control system 5 are assembled on the shuttle frame 11 to form the shuttle 1.

[0033] The track 7 is fixed on the color steel tile roof in the same way as the photovoltaic module, and is laid facing the direction of the photovoltaic array. The track 7 is parallel to the photovoltaic array and the color steel tile roof.

[0034] The bridge 8 is laid between the photovoltaic modules and the frame 11 of the shuttle bus, and every row...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com