Powder metallurgy austenitic stainless steel and preparation method thereof

An austenitic stainless steel, powder metallurgy technology, applied in the field of powder metallurgy materials, can solve problems such as limited application, mechanical properties, wear resistance and corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] The invention provides a method for preparing powder metallurgy austenitic stainless steel, comprising the following steps:

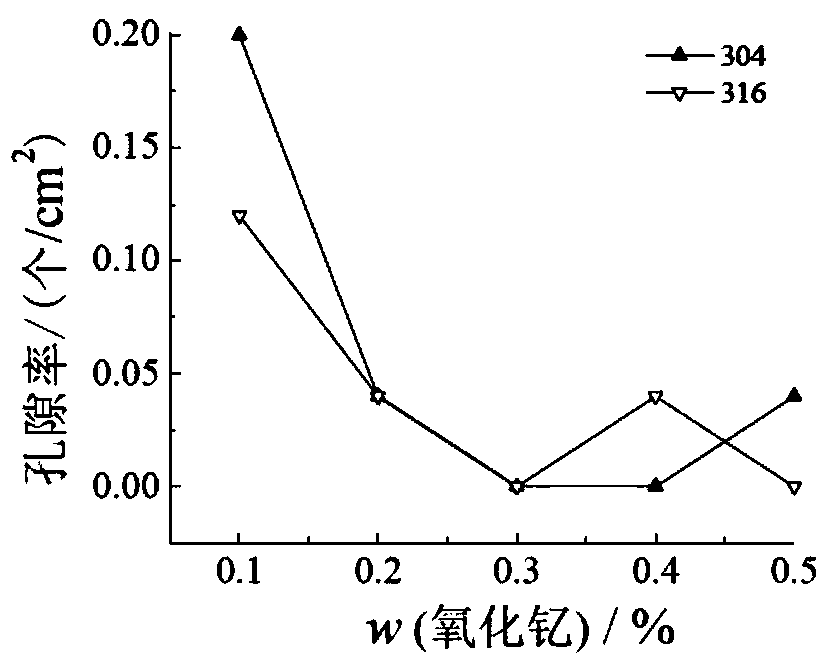

[0026] (1) mixing austenitic stainless steel powder, yttrium oxide powder and lubricant to obtain a mixed powder; the quality of the yttrium oxide powder is 0.2% to 0.4% of the total mass of the austenitic stainless steel powder and yttrium oxide powder;

[0027] (2) Compressing the mixed powder obtained in the step (1) to obtain a green body;

[0028] (3) Sintering the green body obtained in the step (2) to obtain powder metallurgy austenitic stainless steel.

[0029] The invention mixes austenitic stainless steel powder, yttrium oxide powder and lubricant to obtain mixed powder. In the present invention, the mass of the yttrium oxide powder is 0.2-0.4% of the mass of the mixed powder, preferably 0.3%. In the present invention, the yttrium oxide powder is used as a stabilizer, which can reduce precipitated phases under high temperature conditi...

Embodiment 1

[0044] Using 99.3wt% of 400-mesh 316L stainless steel powder, 0.2wt% of 400-mesh yttrium oxide powder and 0.5% of zinc stearate as raw materials, a horizontal ball mill is used for dry grinding and mixing. The tank and balls are made of stainless steel. The ratio is 4:1, the rotational speed is 180r / min, and the ball milling time is 1h.

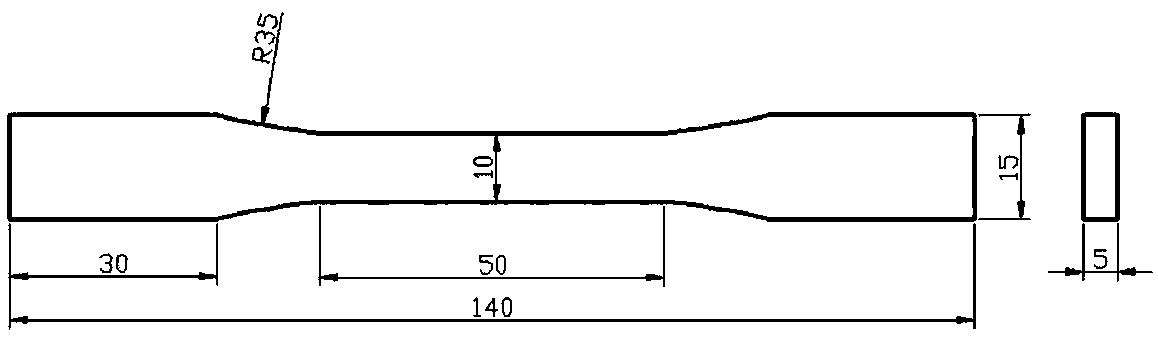

[0045] The uniformly mixed powder is pressed into shape, and the sintered sample used for the electrochemical test is a disc; the one used for the mechanical performance test is a tensile sample, and the size of the tensile sample is as follows figure 2 shown.

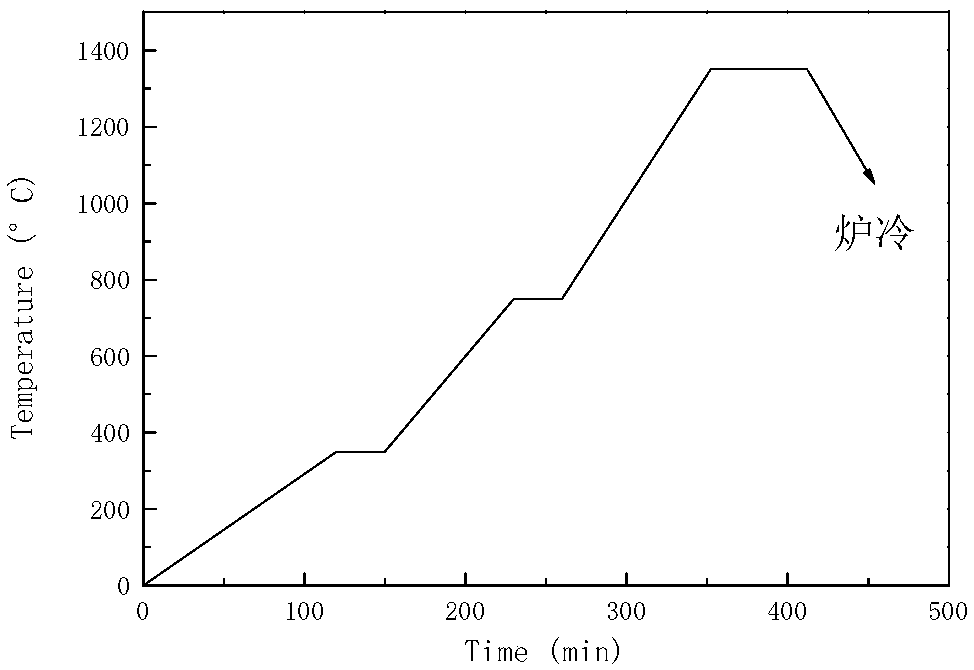

[0046] according to figure 1 For the heat treatment curve shown, the pressed sample is heated up to 350°C for 120 minutes under vacuum conditions, held for 30 minutes, then heated to 750°C for 80 minutes, held for 60 minutes, and then heated to 1350°C for 1 hour after 90 minutes. Cool to obtain powder metallurgy austenitic stainless steel.

Embodiment 2

[0048] According to the method of Example 1, the ratio of raw materials was replaced by 99.2wt% of 316L stainless steel powder, 0.3wt% of yttrium oxide powder and 0.5% of zinc stearate.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com