Circular saw blade laser welding device

A technology of laser welding and laser welding machine, which is applied in the direction of laser welding equipment, tool manufacturing of sawing machine devices, auxiliary devices, etc., which can solve the problem of uneven heating of the saw blade base and saw blade head, high procurement cost of laser welding machines, and limitations Problems such as the penetration rate of laser welding can achieve the effect of reducing power, reducing procurement costs, and improving uniform heating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

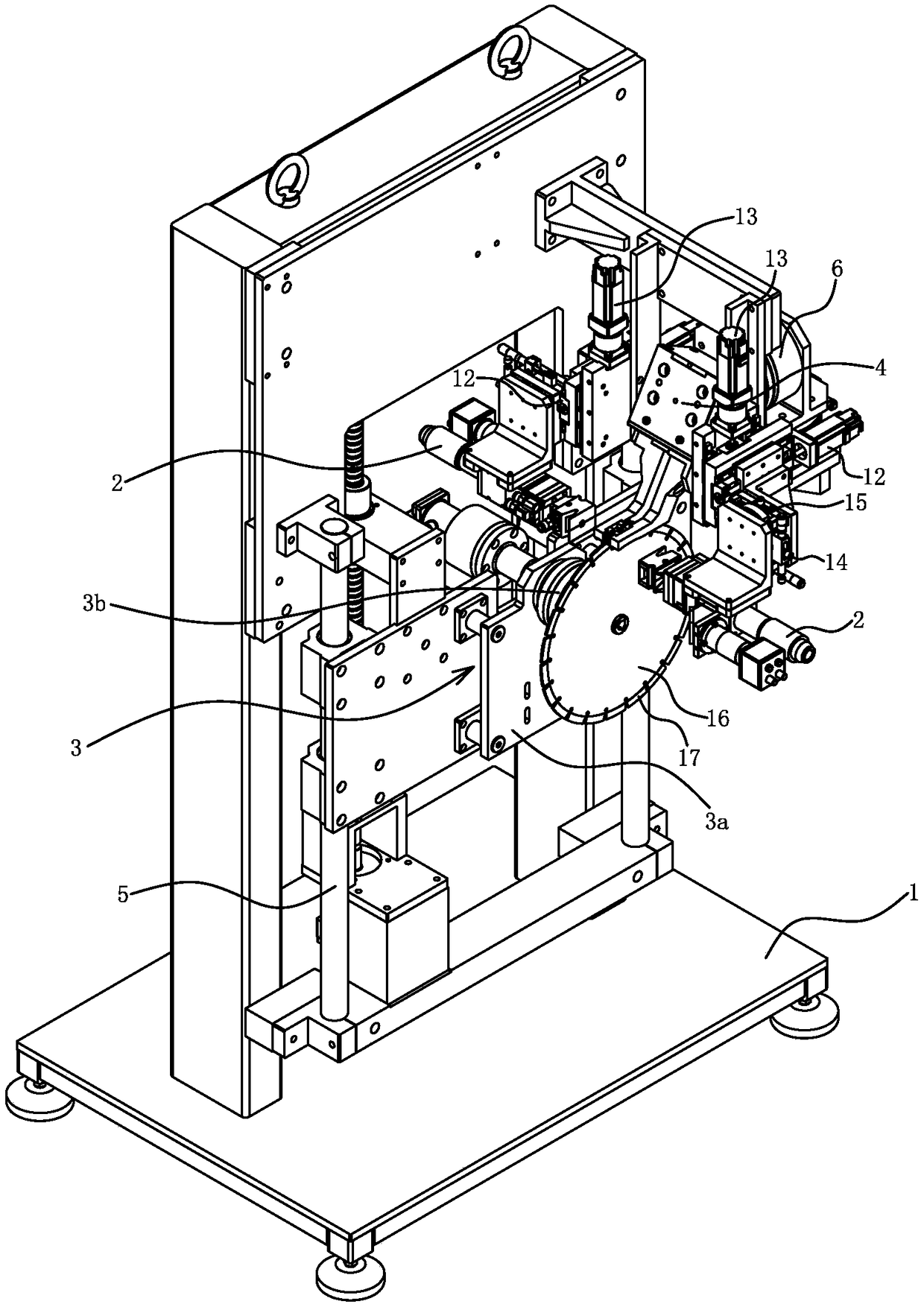

[0014] A circular saw blade laser welding device includes a frame 1, two sets of laser welding machine focusing heads 2, a base clamp 3 and a cutter head clamp 4.

[0015] The frame 1 is a basic part, and the laser welding machine focusing head 2, base fixture 3 and cutter head fixture 4 are all installed on the frame 1.

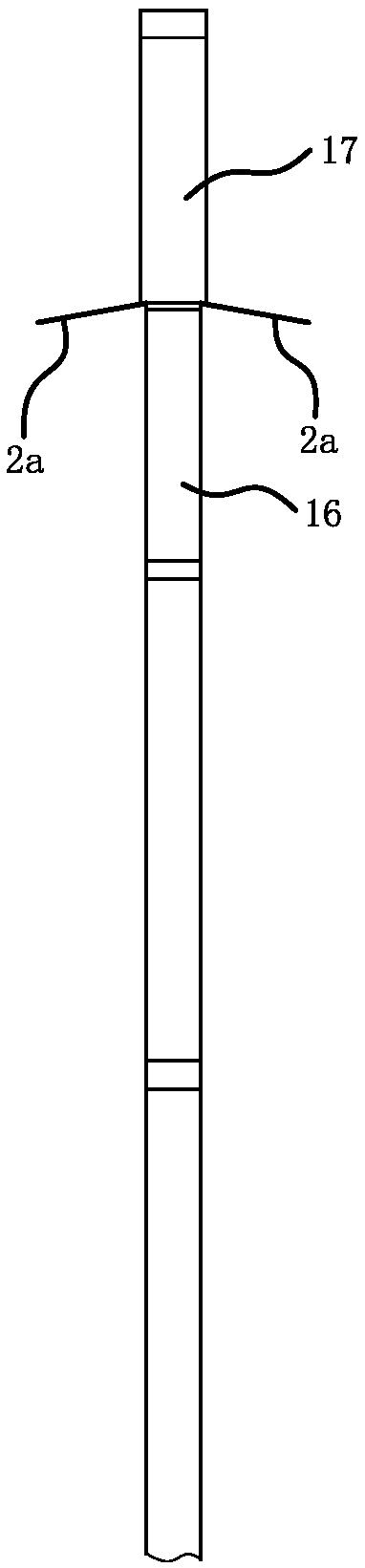

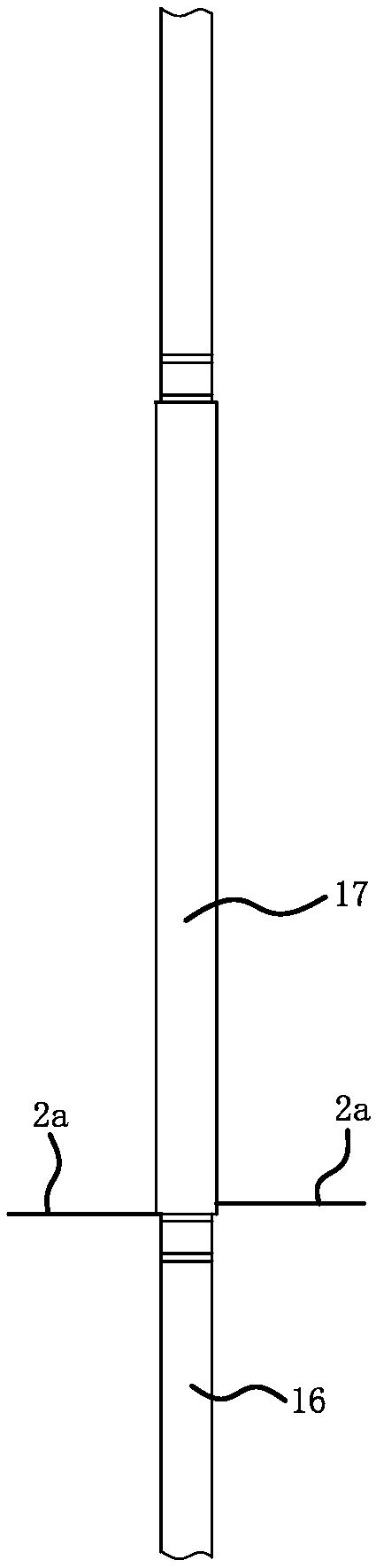

[0016] The base clamp 3 includes a lifting plate 3a and a clamp body 3b, and the clamp body 3b can be flexibly selected according to the diameter and thickness of the saw blade base 16 . The clamping body 3b is located at the front side of the lifting plate 3a, which is convenient for clamping the saw blade base 16, and the clamping body 3b is connected to the lifting plate 3a in rotation; an indexing dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com