Cherry beer and production technology thereof

A cherry beer, production technology technology, applied in the direction of beer brewing, etc., can solve the problems of loss, difficult product fermentation flavor, long time, etc., to achieve strong hop aroma and malt aroma, retain flavor and color, and strong mouth-killing power Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

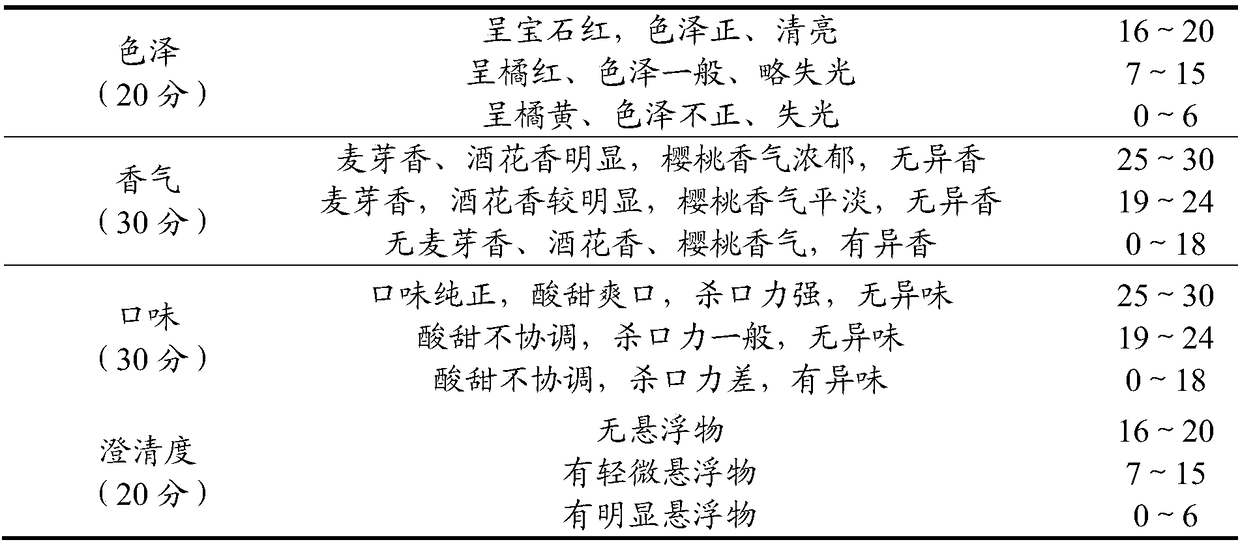

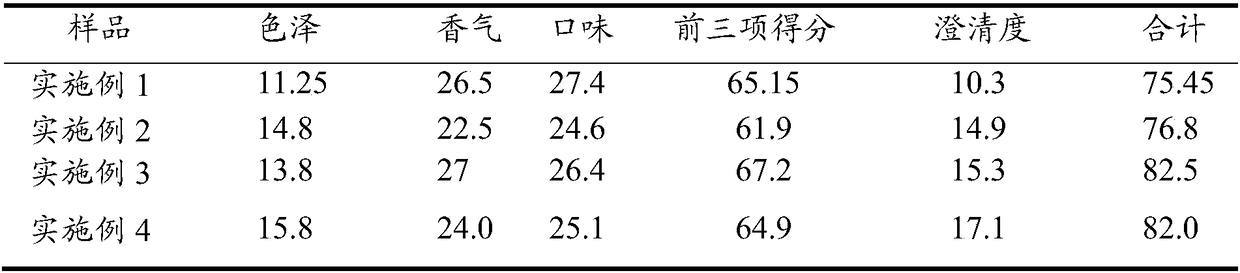

Embodiment 1

[0027] A kind of cherry beer provided by the embodiment of the present invention is specifically composed of the following raw material components in parts by weight: 62 parts of pilsner malt, 29 parts of Munich malt, 3 parts of amber malt, 2 parts of Kristal malt, 4 parts of wheat malt 0 part of Vienna malt, 35 parts of frozen cherry fruit, 0.4 part of hops, 0.05 part of dry yeast, 3 parts of white sugar.

[0028] The production technology of the cherry beer that the embodiment of the present invention provides specifically comprises the following steps:

[0029] S1. Weigh 62 parts by weight of Pilsner malt, 29 parts of Munich malt, 3 parts of amber malt, 2 parts of Kristal malt, 4 parts of wheat malt, 0 part of Vienna malt, 35 parts of frozen cherry fruit, and 0.4 parts of hops 0.05 parts of dry yeast, 3 parts of white sugar;

[0030] S2. Mix and crush the various malts weighed in S1, add water 4 times the total weight of various malts, add the white granulated sugar weighe...

Embodiment 2

[0037] The cherry beer provided by the embodiment of the present invention is specifically composed of the following raw material components in parts by weight: 75 parts of pilsner malt, 0 parts of Munich malt, 0 parts of amber malt, 0 parts of Kristal malt, 10 parts of wheat malt, 15 parts of Vienna malt, 40 parts of frozen cherry fruit, 0.5 part of hops, 0.06 parts of dry yeast, 4 parts of white sugar.

[0038] The production technology of the cherry beer that the embodiment of the present invention provides specifically comprises the following steps:

[0039] S1. Weigh 75 parts by weight of Pilsner malt, 0 parts of Munich malt, 0 parts of amber malt, 0 parts of Kristal malt, 10 parts of wheat malt, 15 parts of Vienna malt, 40 parts of frozen cherry fruit, and 0.5 parts of hops 0.06 parts of dry yeast, 4 parts of white sugar;

[0040] S2. Mix and crush the various malts weighed in S1, add water 5 times the total weight of various malts, add the white granulated sugar weighed ...

Embodiment 3

[0047] The cherry beer provided by the embodiment of the present invention is specifically composed of the following raw material components in parts by weight: 100 parts of Pilsner malt, 0 parts of Munich malt, 0 parts of amber malt, 0 parts of Christau malt, 0 parts of wheat malt, 0 parts of Vienna malt, 30 parts of frozen cherry fruit, 0.3 parts of hops, 0.04 parts of dry yeast, and 2 parts of white sugar.

[0048] The production technology of the cherry beer that the embodiment of the present invention provides specifically comprises the following steps:

[0049] S1. Weigh 100 parts by weight of Pilsner malt, 0 parts of Munich malt, 0 parts of amber malt, 0 parts of Kristal malt, 0 parts of wheat malt, 0 parts of Vienna malt, 30 parts of frozen cherry fruit, and 0.3 parts of hops 0.04 parts of dry yeast, 2 parts of white sugar;

[0050] S2. Mix and crush the various malts weighed in S1, add water 6 times the total weight of various malts, add the white granulated sugar we...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com