Non-metal reinforcing rib for track plate and preparation method thereof

A non-metallic and reinforcing rib technology is applied in the field of fiber composite reinforcing bars, which can solve the problems of inability to obtain track slab reinforcing bars, affecting train communication safety, and heavy track slab quality, so as to improve communication safety and impact strength. The effect of high, high structural strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

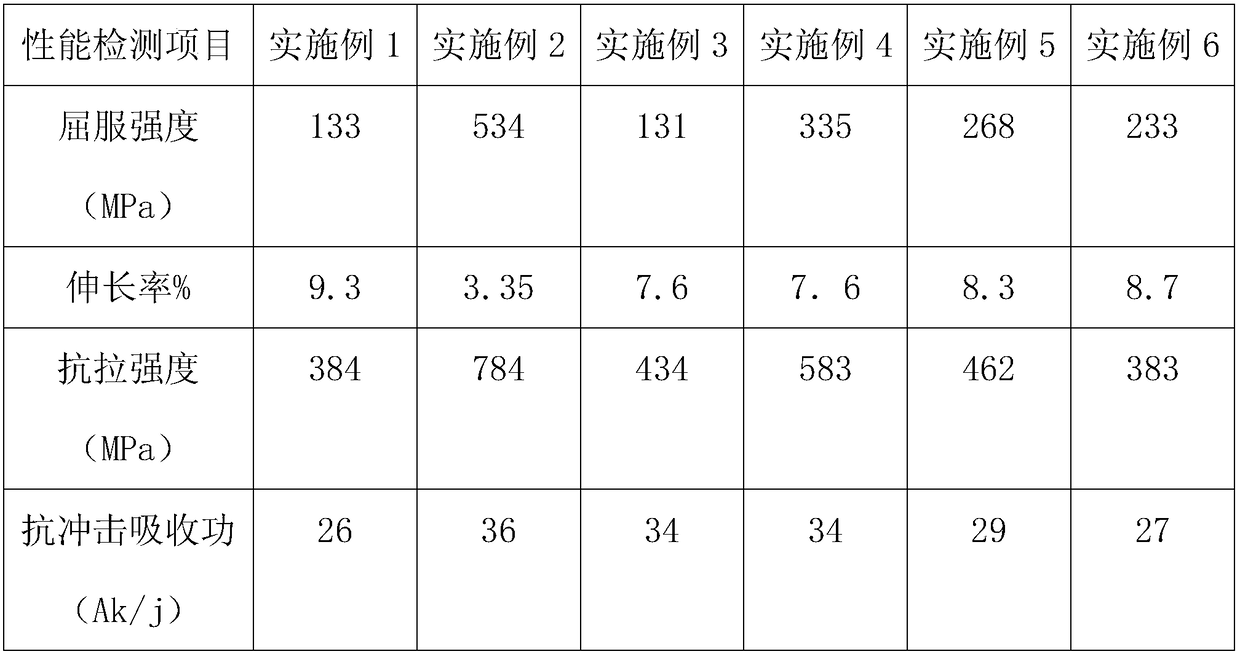

Examples

Embodiment 1

[0034]The present invention is a non-metallic reinforcing bar for track slabs in rail traffic engineering (such as high-speed rail), which is a concrete solidification structure containing fiber ropes, with a diameter of about 8mm, and the diameter of fiber ropes is about 6mm. Obviously, the fiber rope The diameter is smaller than the overall diameter of the non-metallic stiffener. The aforementioned fiber rope is a weaving structure of a fiber rope made of organic long fibers, AR-type glass long fibers and basalt long fiber twisted fiber lines, that is, the twisted fiber lines of specific fiber materials are first woven into fiber ropes, and then twisted into fiber ropes. The fiber strands are woven into the product fiber ropes, and the aforementioned fiber strands contain a thermosetting polymer gel.

[0035] The preparation method of the above-mentioned non-metallic reinforcing ribs includes the fiber rope preparation process, the concrete slurry preparation process and the...

Embodiment 2

[0049] The present invention is the non-metallic reinforcing bar that track plate is used in rail traffic engineering, and it is the concrete solidification structure that contains fiber rope, and diameter is about 51mm, and the diameter of fiber rope wherein is about 48mm, obviously, the diameter of fiber rope is smaller than non-metallic reinforcement. The overall diameter of the metal stiffener. The aforementioned fiber rope is a weaving structure of a fiber rope made of organic long fibers, AR-type glass long fibers and basalt long fiber twisted fiber lines, that is, the twisted fiber lines of specific fiber materials are first woven into fiber ropes, and then twisted into fiber ropes. The fiber strands are woven into the product fiber ropes, and the aforementioned fiber strands contain a thermosetting polymer gel.

[0050] The preparation method of the above-mentioned non-metallic reinforcing ribs includes the fiber rope preparation process, the concrete slurry preparatio...

Embodiment 3

[0065] The present invention is the non-metallic reinforcement bar that track plate is used in rail transit project, and it is the concrete solidification structure that contains fiber rope, and diameter is about 13mm, and the diameter of fiber rope wherein is about 10mm, obviously, the diameter of fiber rope is smaller than non-metallic reinforcement. The overall diameter of the metal stiffener. The aforementioned fiber rope is a weaving structure of a fiber rope made of organic long fibers, AR-type glass long fibers and basalt long fiber twisted fiber lines, that is, the twisted fiber lines of specific fiber materials are first woven into fiber ropes, and then twisted into fiber ropes. The fiber strands are woven into the product fiber ropes, and the aforementioned fiber strands contain a thermosetting polymer gel.

[0066] The preparation method of the above-mentioned non-metallic reinforcing ribs includes the fiber rope preparation process, the concrete slurry preparation ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com