Uplink and downlink overhead contact line equipment parallel state identification method of direct feeding traction network

A state identification and traction network technology, applied in the direction of fault location, fault detection according to conductor type, etc., can solve problems such as changes in operating status and inconsistent connection methods, and achieve good versatility, easy implementation, and real-time monitoring and feedback. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

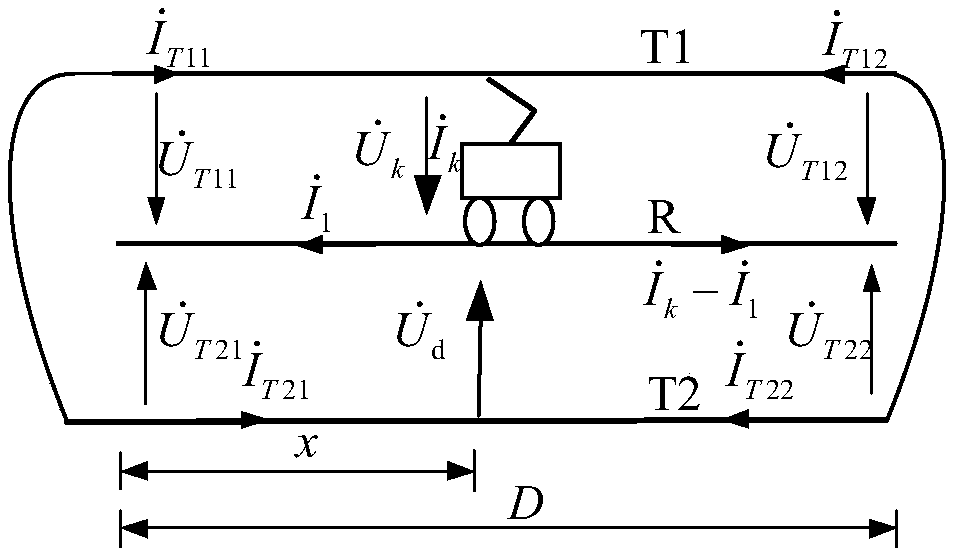

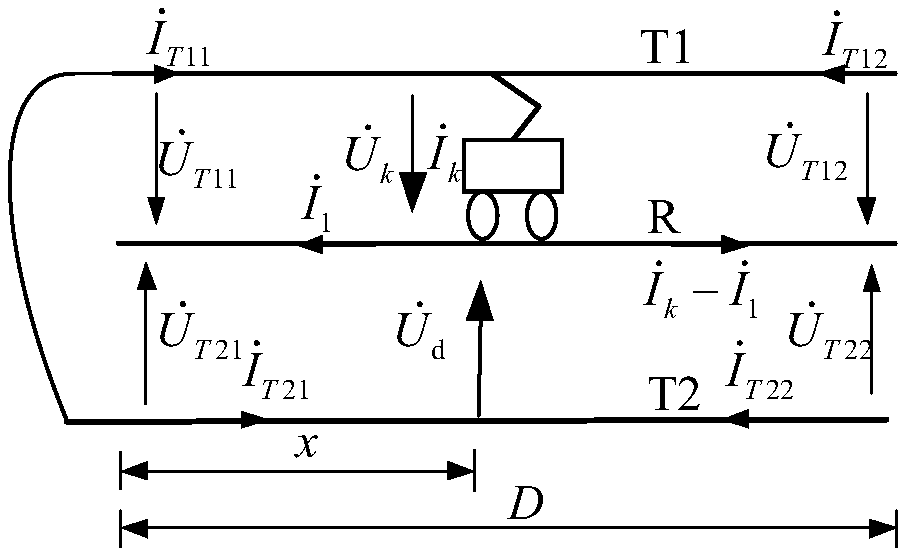

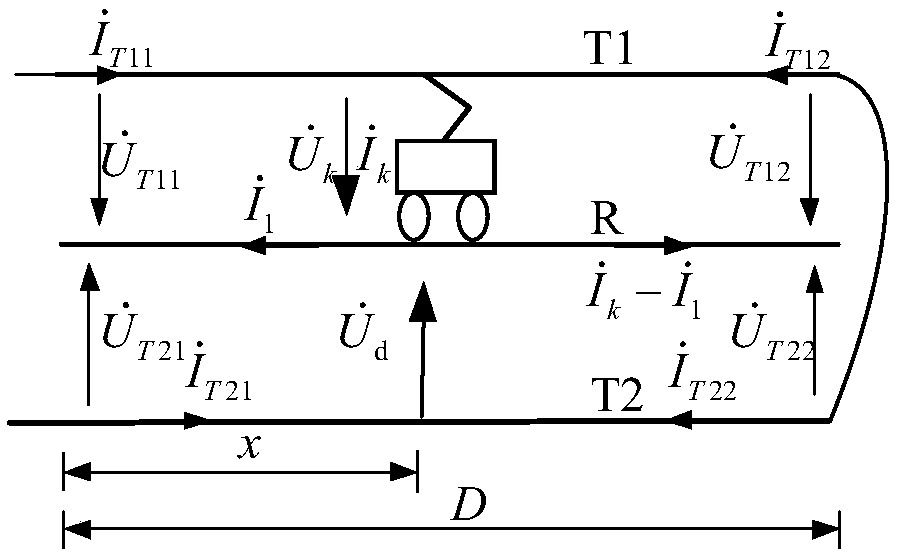

[0029] like figure 1 As shown, assume that the segment length of the electrified railway direct-supply traction network is D, the head and the end of the uplink and downlink contact lines are connected in parallel, and the self-impedance of the uplink contact line T1 and the downlink contact line T2 is both Z T , the self-impedance of rail R is Z R , the mutual impedance between the uplink contact line T1 and the downlink contact line T2 is Z TT ;Synchronously measure the voltage phasor and current phasor at both ends of each segment of the direct supply traction network, including the voltage phasor at the head end of the uplink contact line T1 and head current phasor terminal voltage phasor and terminal current phasor Voltage phasor at the head end of downlink contact line T2 and head current phasor terminal voltage phasor and terminal current phasor Assume that the current is taken at a distance of x km from the head end of the section of the direct supply t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com