Double-heat-conductive-piece clamping-plate-type LED display unit module

A technology for LED display lights and display units, which is applied to instruments, identification devices, etc., can solve the problems of display module deformation, frequent failures, and increased dead lights rate, and achieve the effect of enhancing structural sealing and ensuring stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

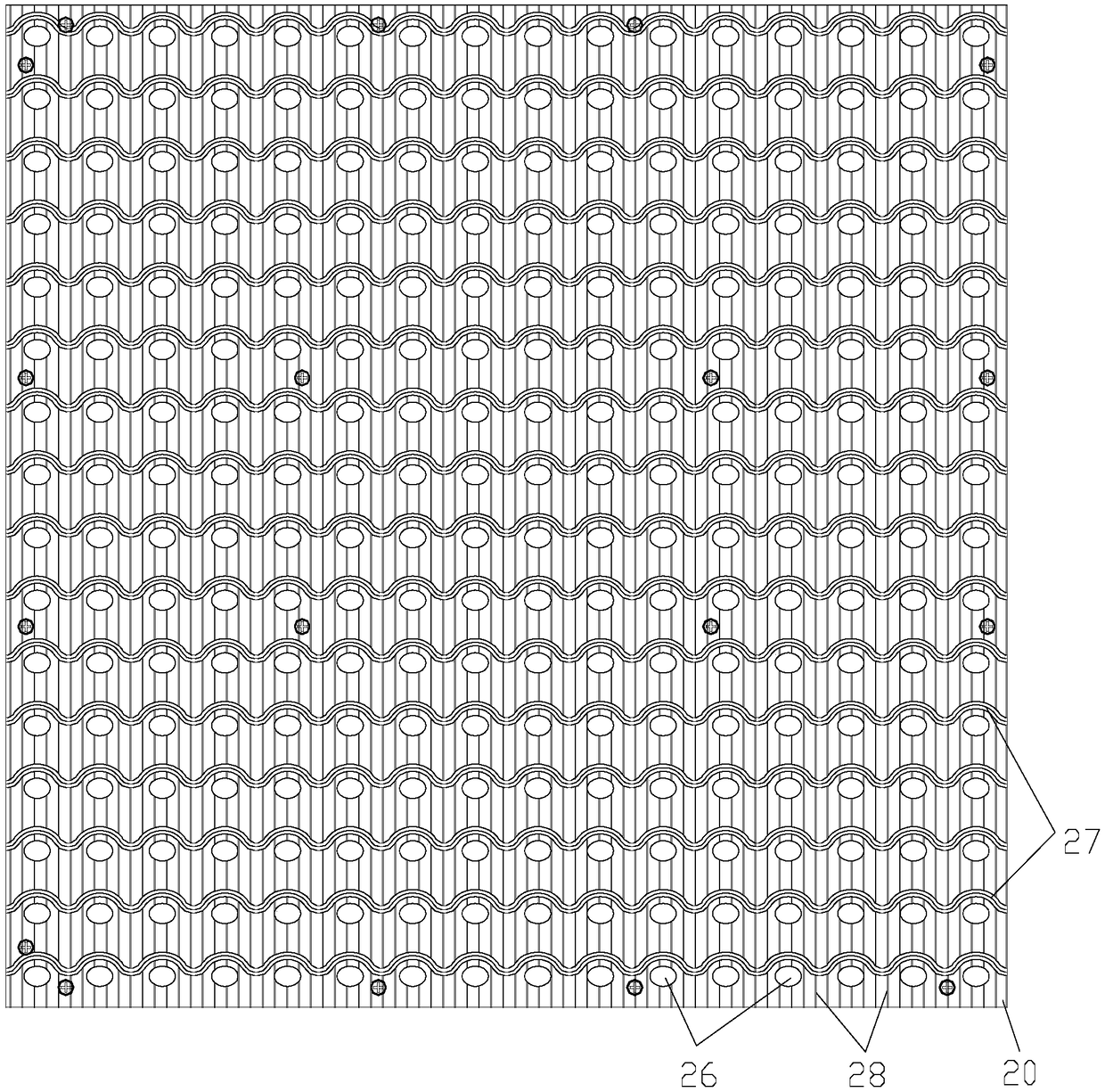

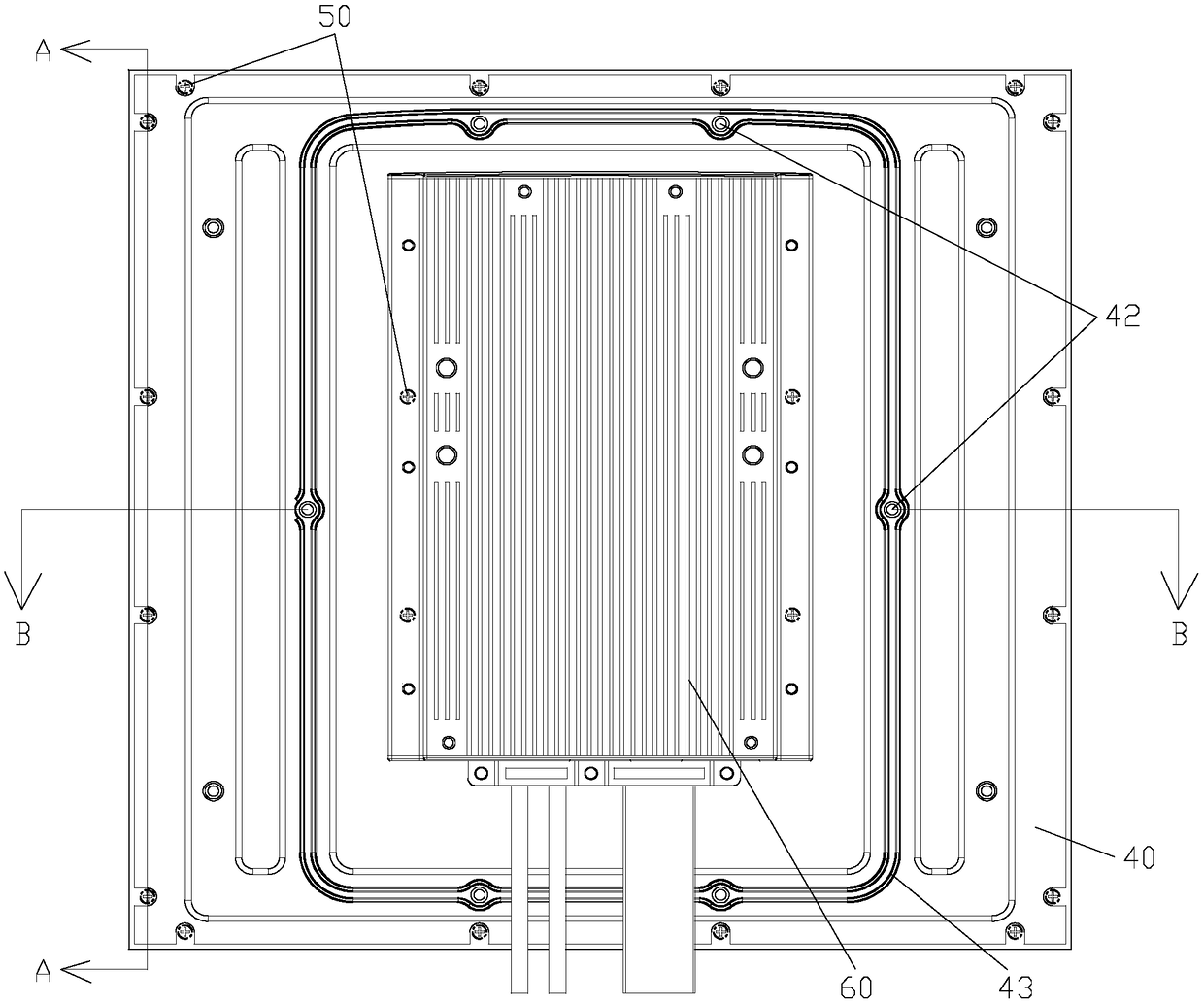

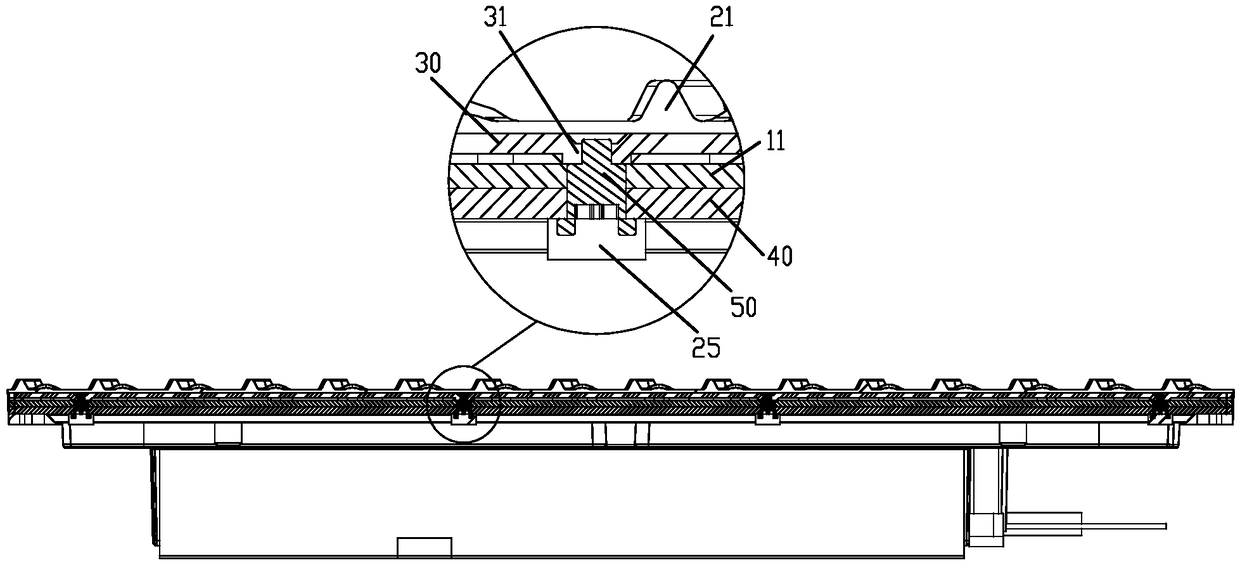

[0035] Such as Figure 1 to Figure 9 As shown, the present embodiment provides a double heat-conducting sheet splint type LED display unit module, which includes an LED display lamp board 10, a sealant 20 (it can be colored and transparent liquid silica gel according to specific conditions and injected through a glue injection machine) Plastic mold molding), heat conduction panel 30, heat conduction back plate 40 and several heat conduction pillars 50; wherein, LED display lamp board 10 comprises circuit board 11, IC chip 12 and several pastes mounted on the back surface of circuit board 11 The LED light-emitting tubes 13 installed on the front surface of the circuit board 11 and distributed in an array; the circuit board 11 is stacked and clamped b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com