Wear-resistant enameled wire

A wear-resistant varnish and covered wire technology, applied to conductors, insulated cables, electrical components, etc., can solve the problems of affecting the normal use of enameled wires, shortening the service life of enameled wires, and short service life, so as to prevent paint film from falling off and improve adhesion Performance, the effect of reducing the shedding rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but not as a basis for limiting the present invention.

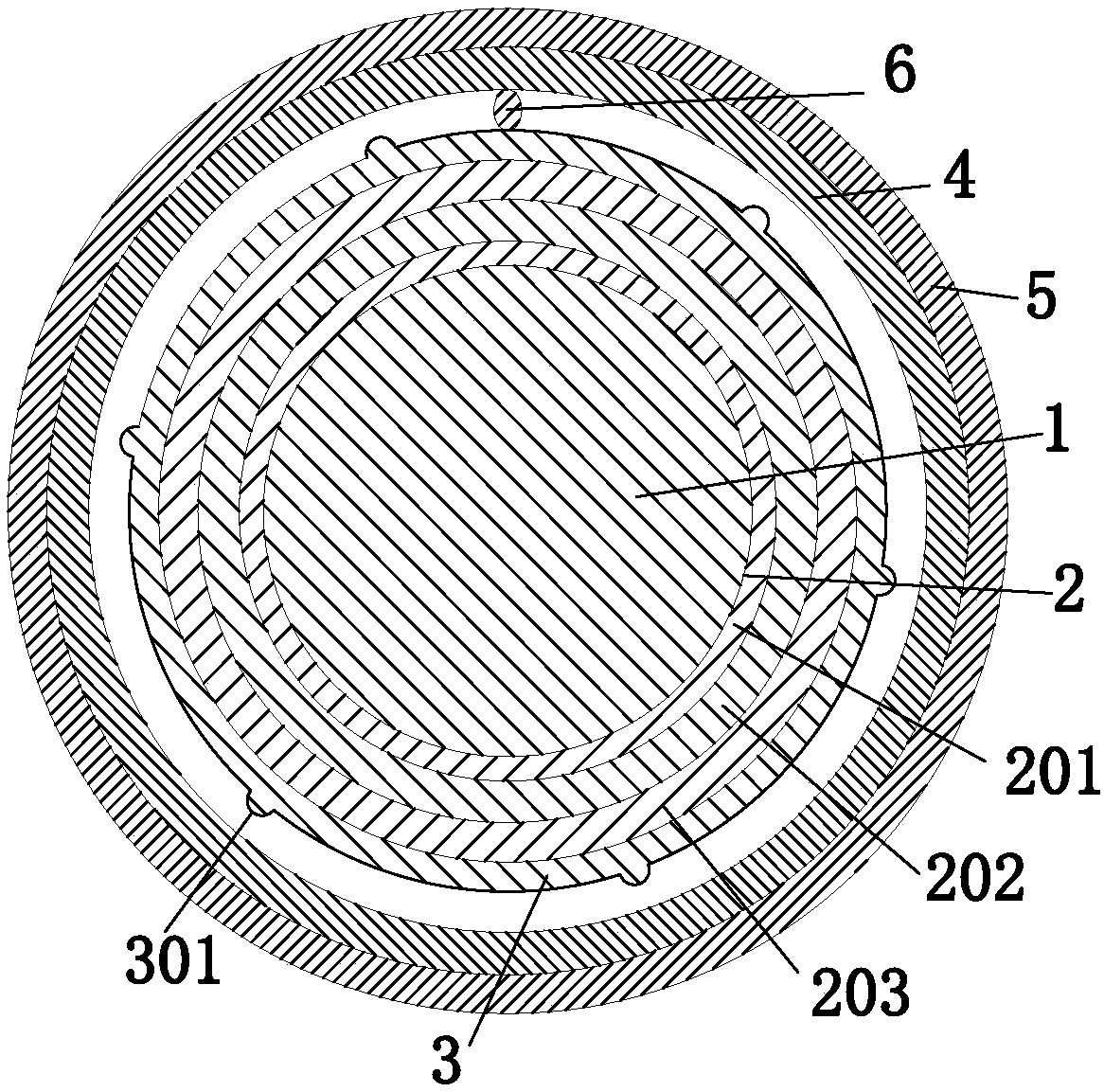

[0014] Example. A wear-resistant enameled wire, constituted as figure 1 As shown, it includes round copper wire 1, round copper wire 1 is provided with insulating layer 2, insulating layer 2 is provided with first nylon coating 3 and second nylon coating 4, and second nylon coating 4 is provided with poly Amide-imide paint layer 5, carbon nanotube layer 6 is arranged between the first nylon coating 3 and the second nylon coating 4; The insulating layer 2 includes polyamide paint layer 201, metal oxide polyamide imide The amine paint layer 202 and the polyurethane paint layer 203, and the thickness ratio between the polyamide paint layer 201, the metal oxide polyamideimide paint layer 202 and the polyurethane paint layer 203 is 1:1.5:2.

[0015] The polyamide-imide paint layer 5 includes five layer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap