Flip-chip method

A flip-chip and barrier layer technology, which is applied in the manufacture of electrical components, electrical solid devices, semiconductor/solid devices, etc., can solve the problems of poor solder layer quality and easy connection, and achieve the effects of improving quality, avoiding short circuits, and avoiding collapse

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] As mentioned in the background, the flip-chip method formed in the prior art will result in poor quality of the solder layer, and adjacent solder layers are easily connected together.

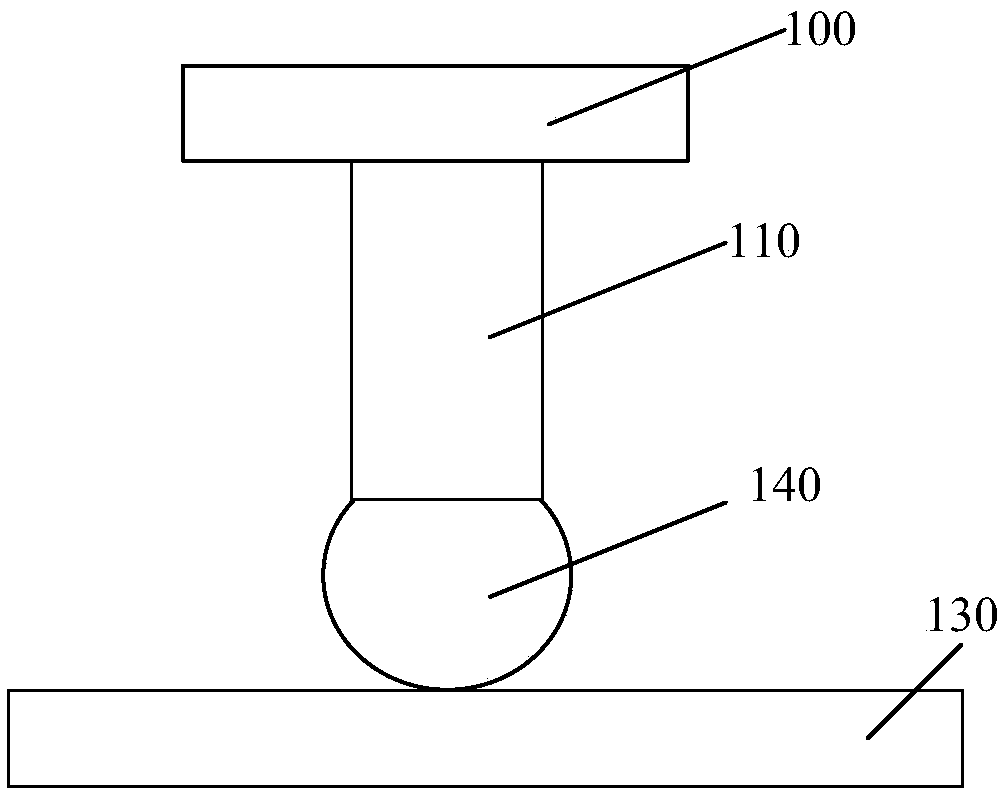

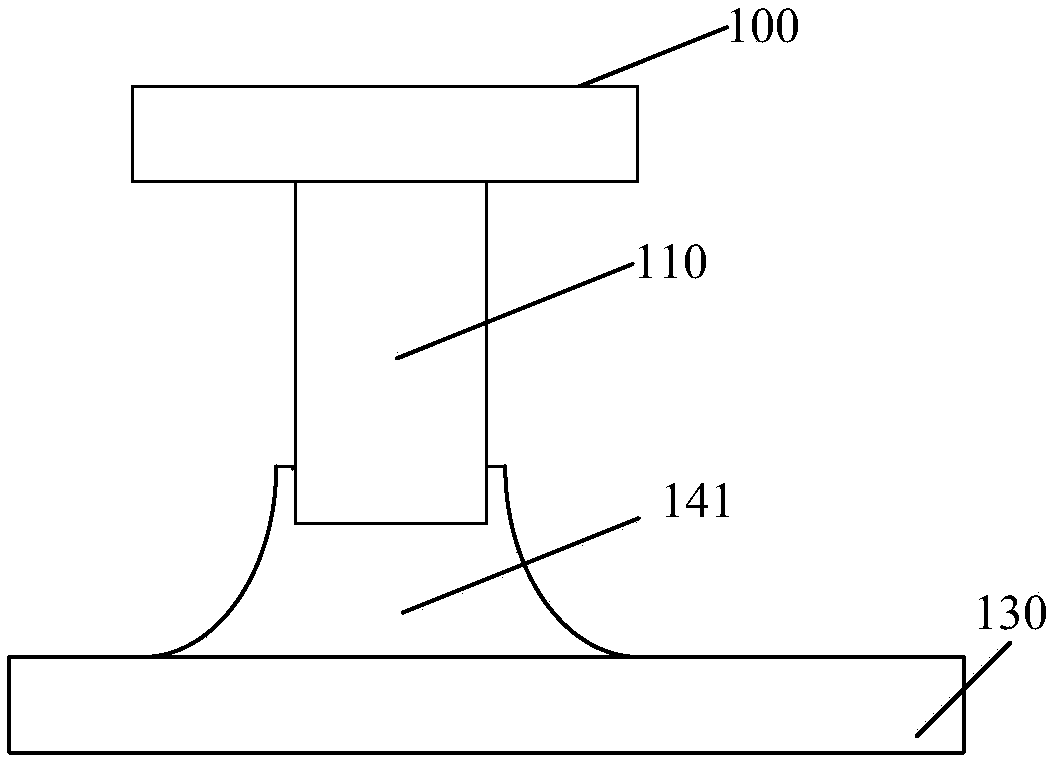

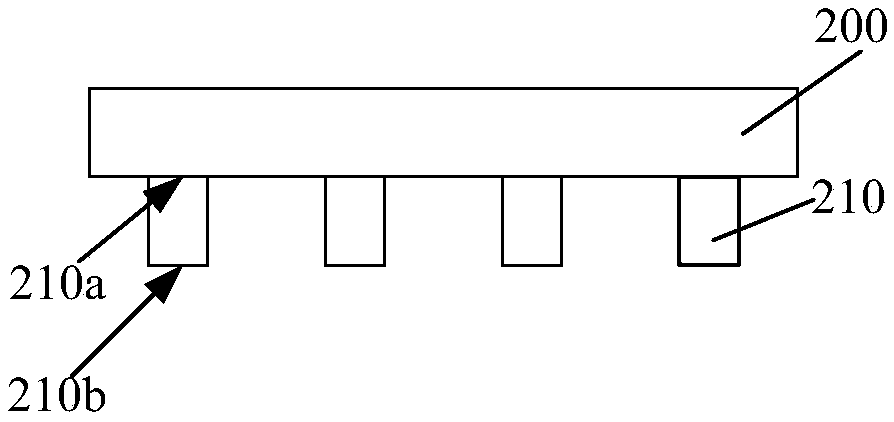

[0022] Figure 1 to Figure 2 is a schematic diagram of the structure of the flip-chip method.

[0023] refer to figure 1 , providing a semiconductor chip 100, a conductive connecting column 110 and a carrier plate 130, the conductive connecting column 110 has an opposite first surface and a second surface; the conductive connecting column 110 is fixed on the surface of the semiconductor chip 100, the first Facing the semiconductor chip 100; the solder ball 140 is fixedly arranged on the second surface of the conductive connection column 110; after that, the semiconductor chip 100, the conductive connection column 110 and the solder ball 140 are placed on the surface of the carrier board 130, and the solder ball 140 is connected to the surface of the carrier plate 130. The carrier board...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap