Improved water reaction device

A reaction device and an improved technology, which are applied in the field of supercritical water preparation, can solve the problems that the production cost and the use cost are difficult to be accepted by small and medium-sized enterprises.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

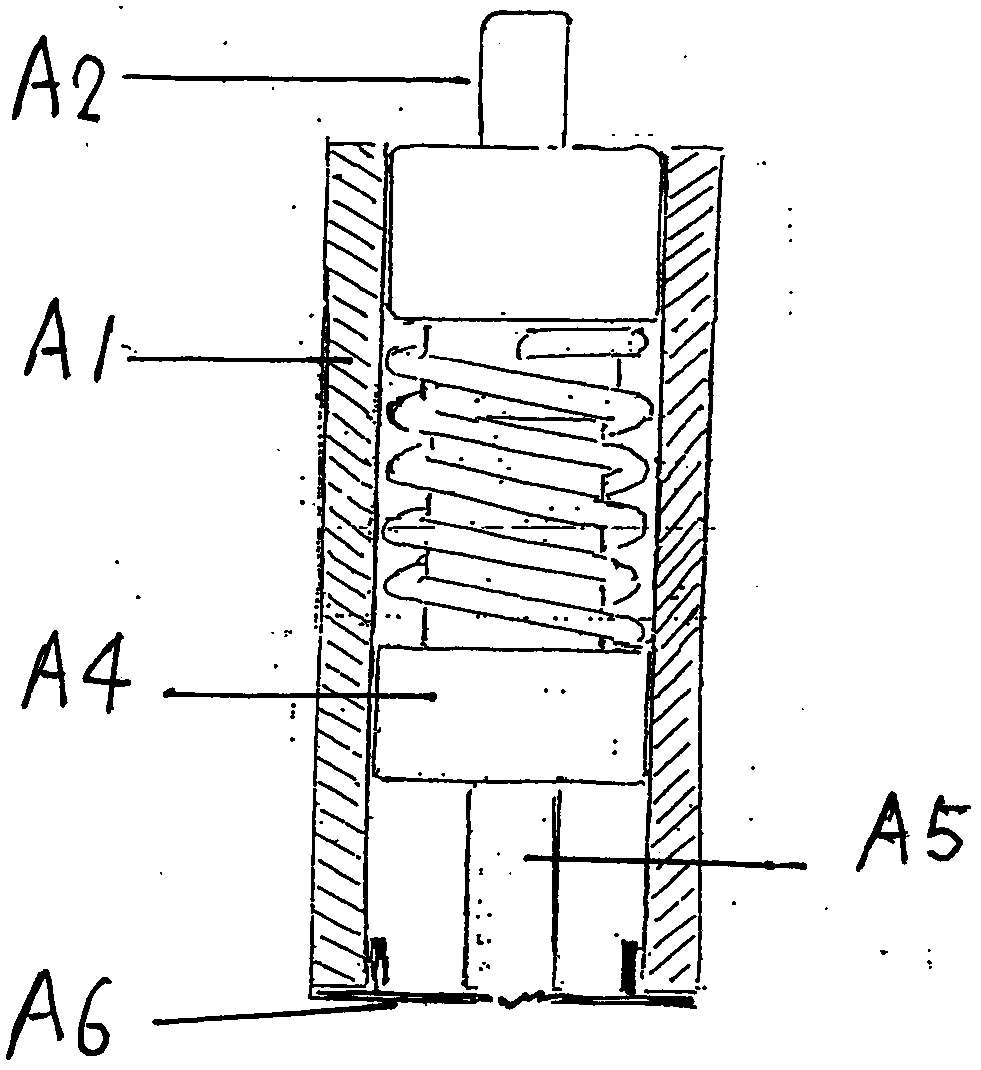

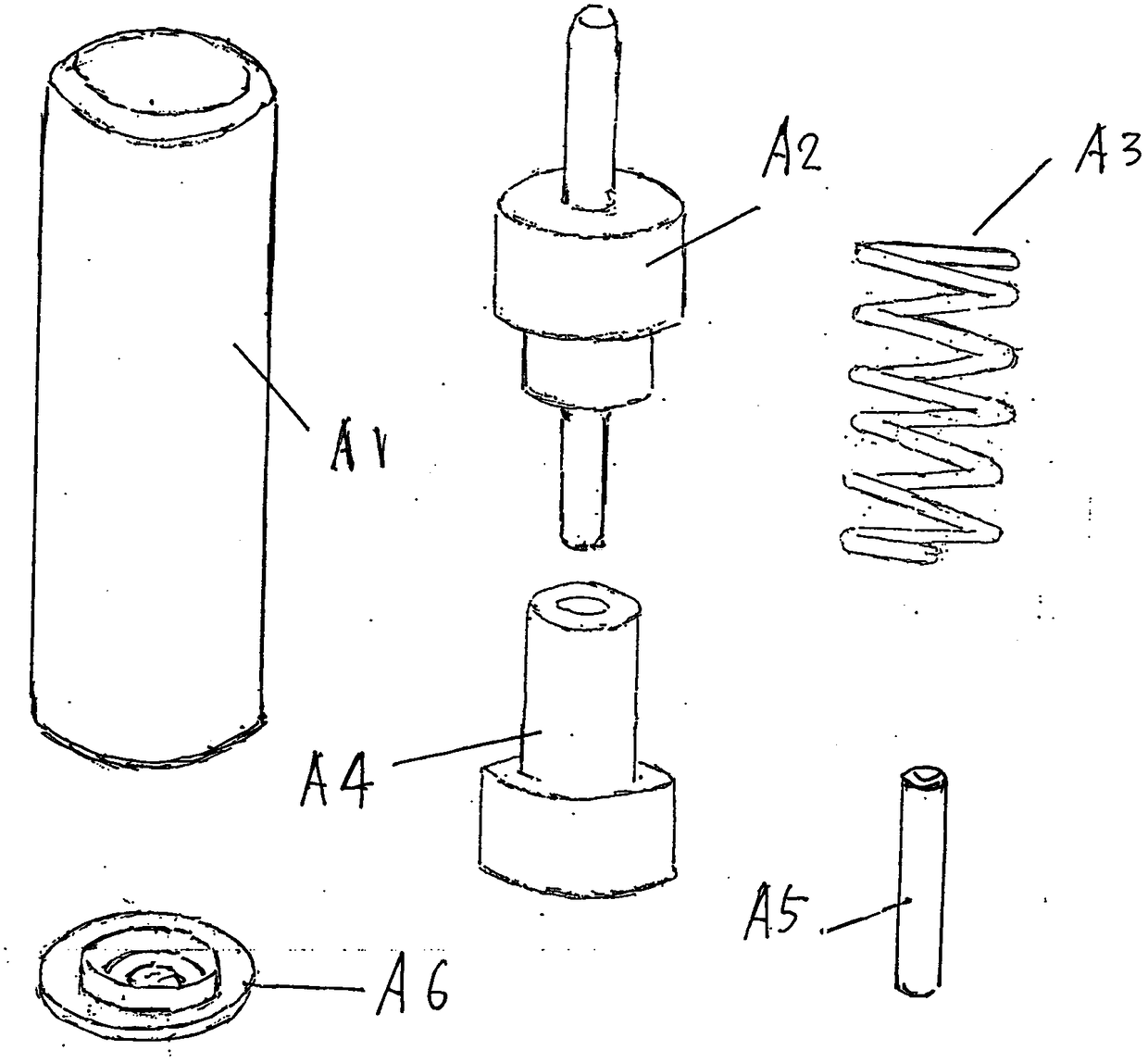

[0006] The accompanying drawings depict a non-limiting embodiment of the present application. Such as figure 2 and image 3 The discharge type fuel rod A shown and described is composed of a high temperature resistant insulating sleeve A1, a plunger-shaped power input terminal A2, a compression spring A3, a conductive piston A4, a discharge end tube A5 and an aluminum sealing cover A6. The length of the high-temperature-resistant insulating sleeve A1 is equal to the length of the restrained reaction sleeve B2 in the water reaction vessel B, and the discharge end pipe A5 is directly formed of a tubular aluminum-magnesium alloy or as Figure 4 It is shown that the flake or granular filler made by mixing aluminum powder or magnesium powder with a binder is used as the core material A5a to fill in the tubular aluminum alloy A5, and it is prepared in the aluminum sealing cap A6. covered holes;

[0007] Such as Figure 5 The shown and described main device is composed of a wate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com