Oil paint raw material grinder

A pulverizer and raw material technology, applied in the field of paint production, can solve the problems of uneven shape, large volume of paint raw materials, incomplete pulverization, etc., and achieve the effect of improving pulverization efficiency, increasing extrusion area, and not easy to wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

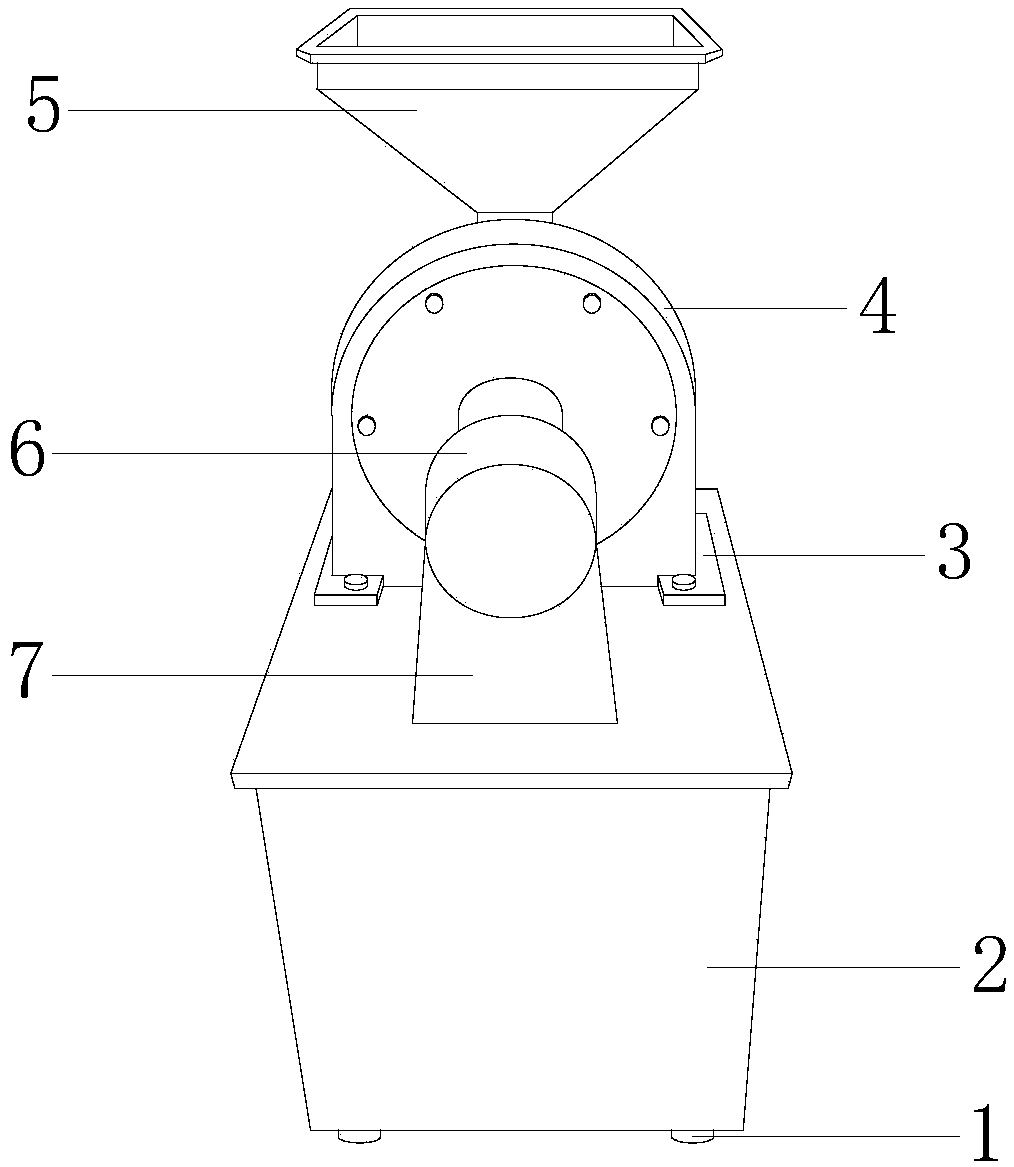

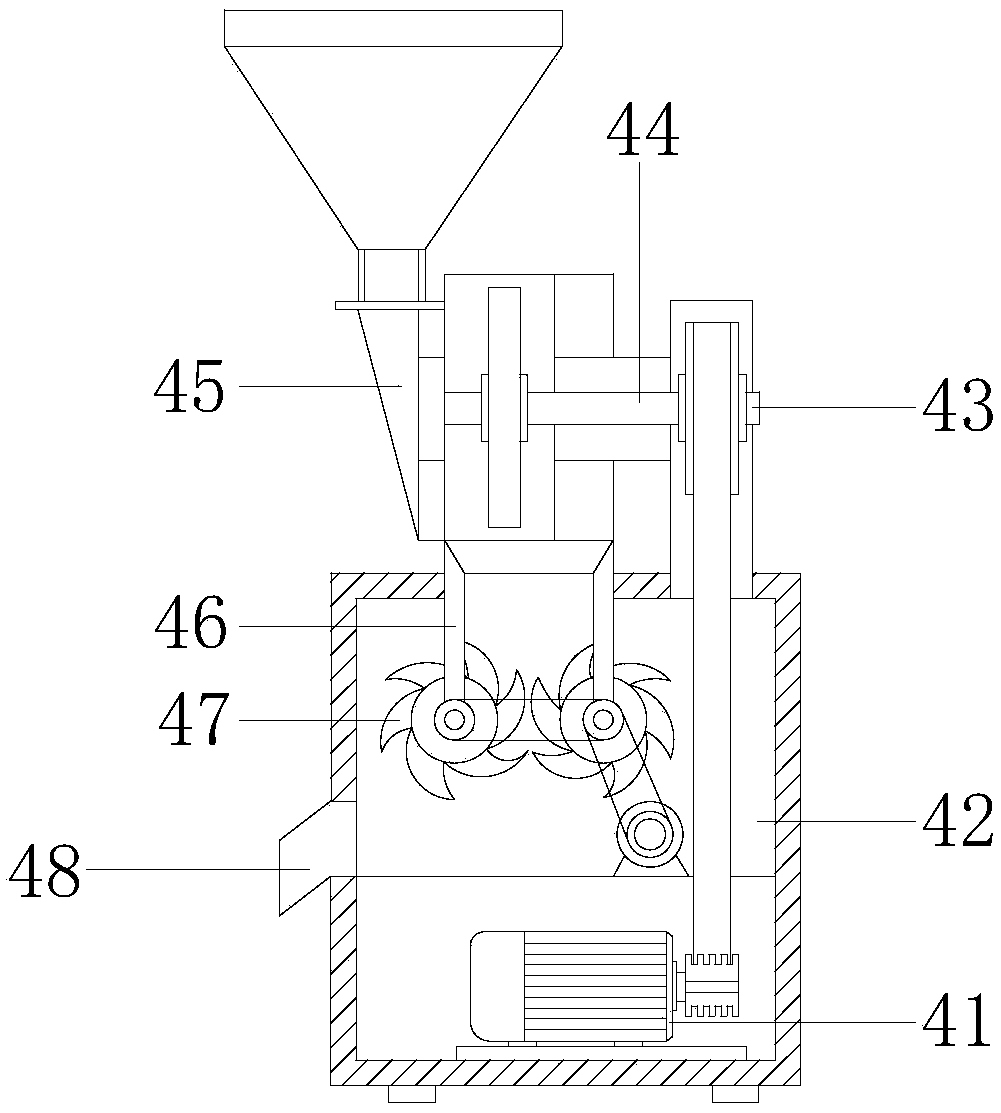

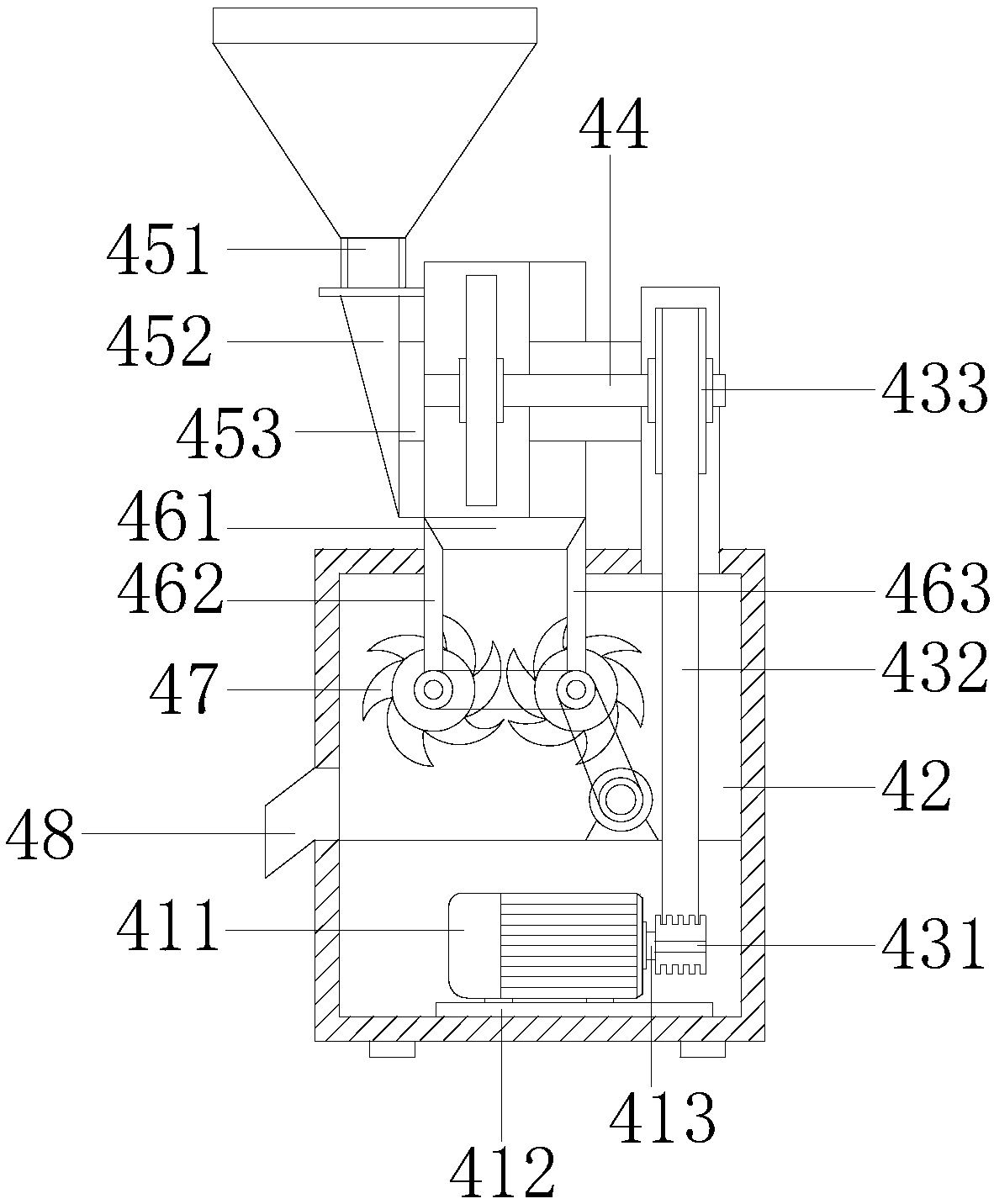

[0022] Such as Figure 1-Figure 5As shown, the present invention provides a paint raw material pulverizer, the structure of which includes: a supporting foot 1, a base 2, a limiting plate 3, a pulverizing device 4, a feeding hopper 5, a main bearing 6, a bracket 7, and the supporting There are four feet 1, which are evenly installed on the bottom of the base 2 and adopt a clearance fit. The cross section of the base 2 is a rectangular structure and is vertically fixed on the upper end of the supporting foot 1 and is integrated with the crushing device 4. The limiting plate 3 is provided with two and is vertically attached to the top of the base 2 and is fixed with the crushing device 4 by nuts. connected, the feed hopper 5 is vertically fixed on the top of the crushing device 4 and matched, the main bearing 6 is embedded horizontally inside the crushing device 4 and is movably connected, and the bracket 7 is horizontally nested in the outer ring of the main bearing 6 And the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com