Color selector separation system capable of effectively screening coarse cereals

A technology of separation system and color sorter, which is applied in the field of color sorter separation system for effective screening of miscellaneous grains, which can solve the problems of low separation efficiency of color sorters, separation of miscellaneous grains, inconvenience of long-term use, etc., and achieve high separation efficiency and easy operation and use ,Easy for long-term use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

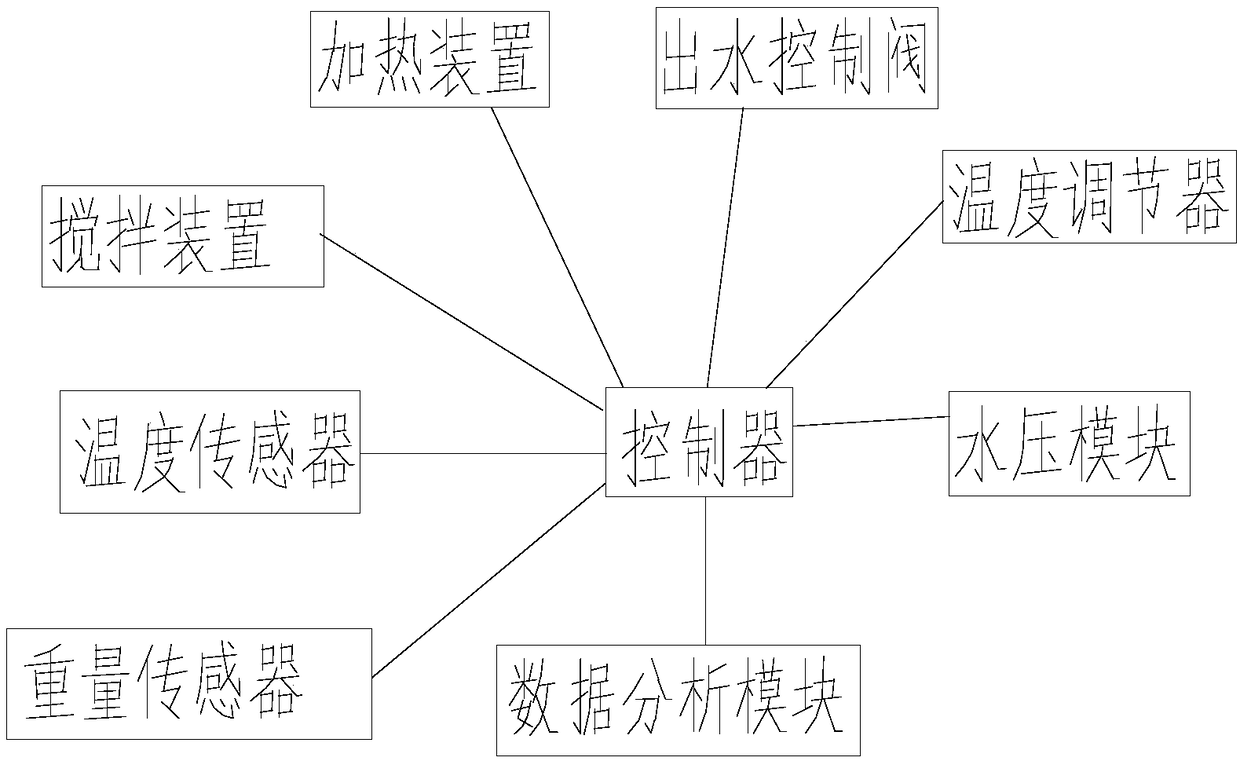

[0019] Such as figure 1 As shown, the color sorter separation system for effectively screening miscellaneous grains of the present invention includes a temperature sensor and a controller, and the controller is connected with a stirring device, a heating device, a water outlet control valve, a temperature regulator, a hydraulic module, a data analysis module and A weight sensor, the weight sensor is used to detect the weight of miscellaneous grains, when the data analysis module obtains the weight signal of the weight sensor exceeds the A value, the controller controls the stirring device to stop stirring, and the miscellaneous grains are discharged, and the controller adjusts the grain through the hydraulic module The water output in the water control valve. The stirring frequency of the stirring device is increased by increasing the pressure of the water outlet in the water outlet control valve. The value of A is two-thirds of the weight of the screening box for loading mis...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap