Novel bearing cleaning device

A new type of bearing cleaning technology, applied in cleaning methods and utensils, cleaning methods using tools, cleaning methods using liquids, etc., can solve the problems of difficult to remove impurities, insufficient bearing cleaning, poor cleaning effect, etc. The effect of convenience, reduced collision, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

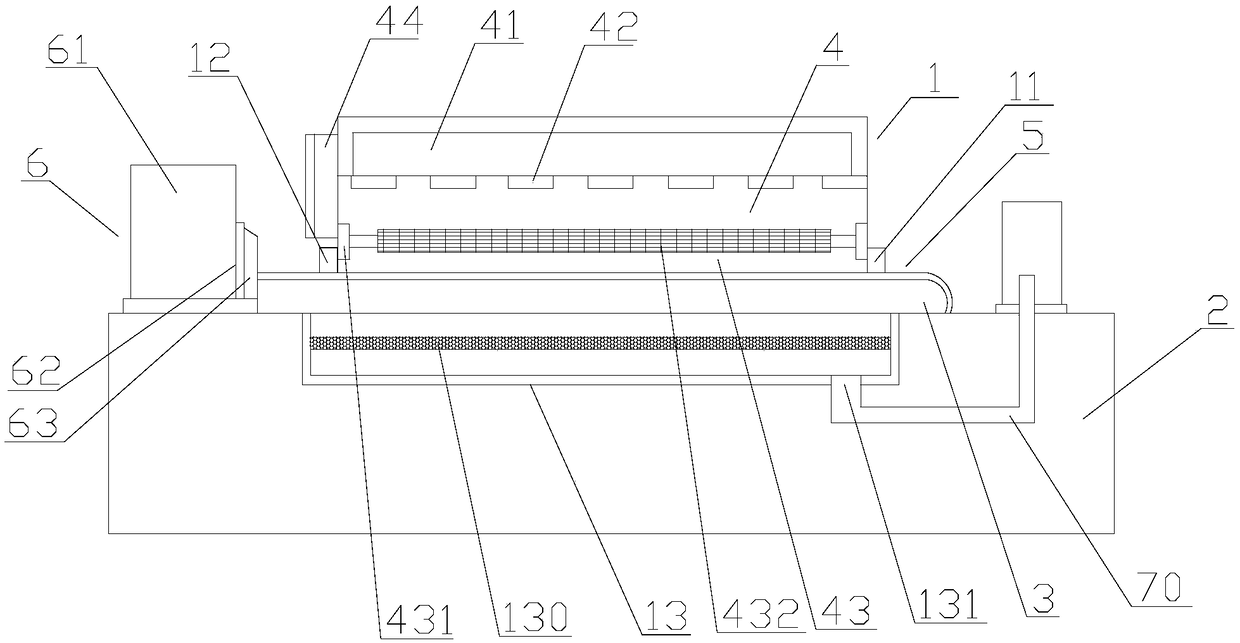

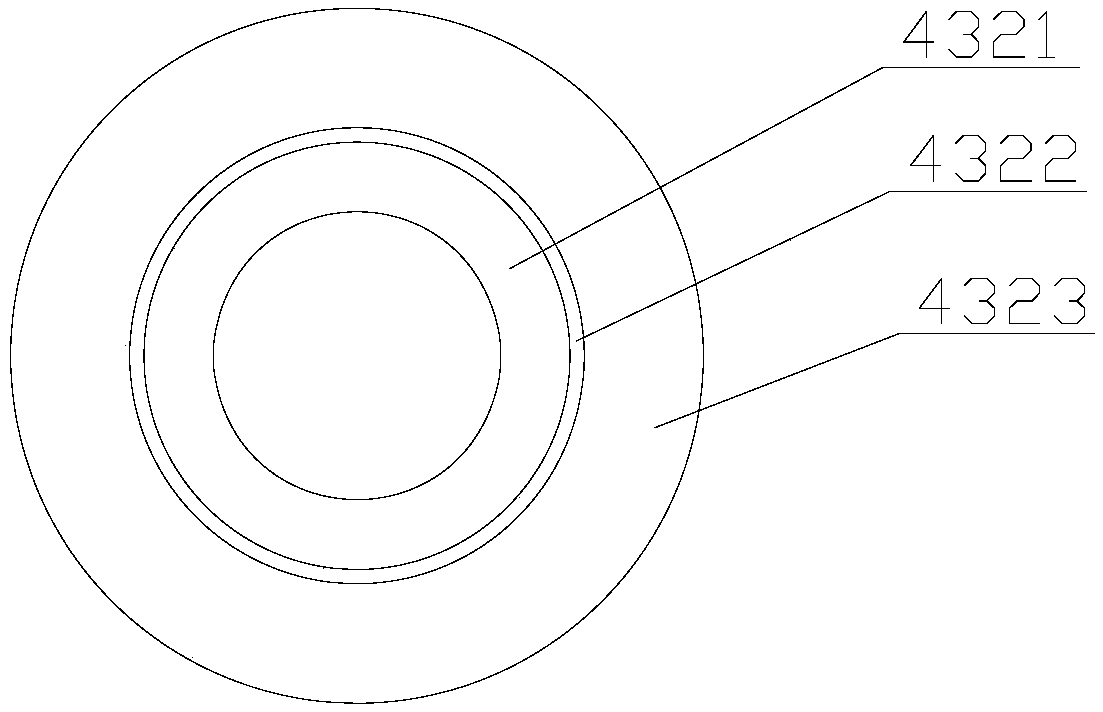

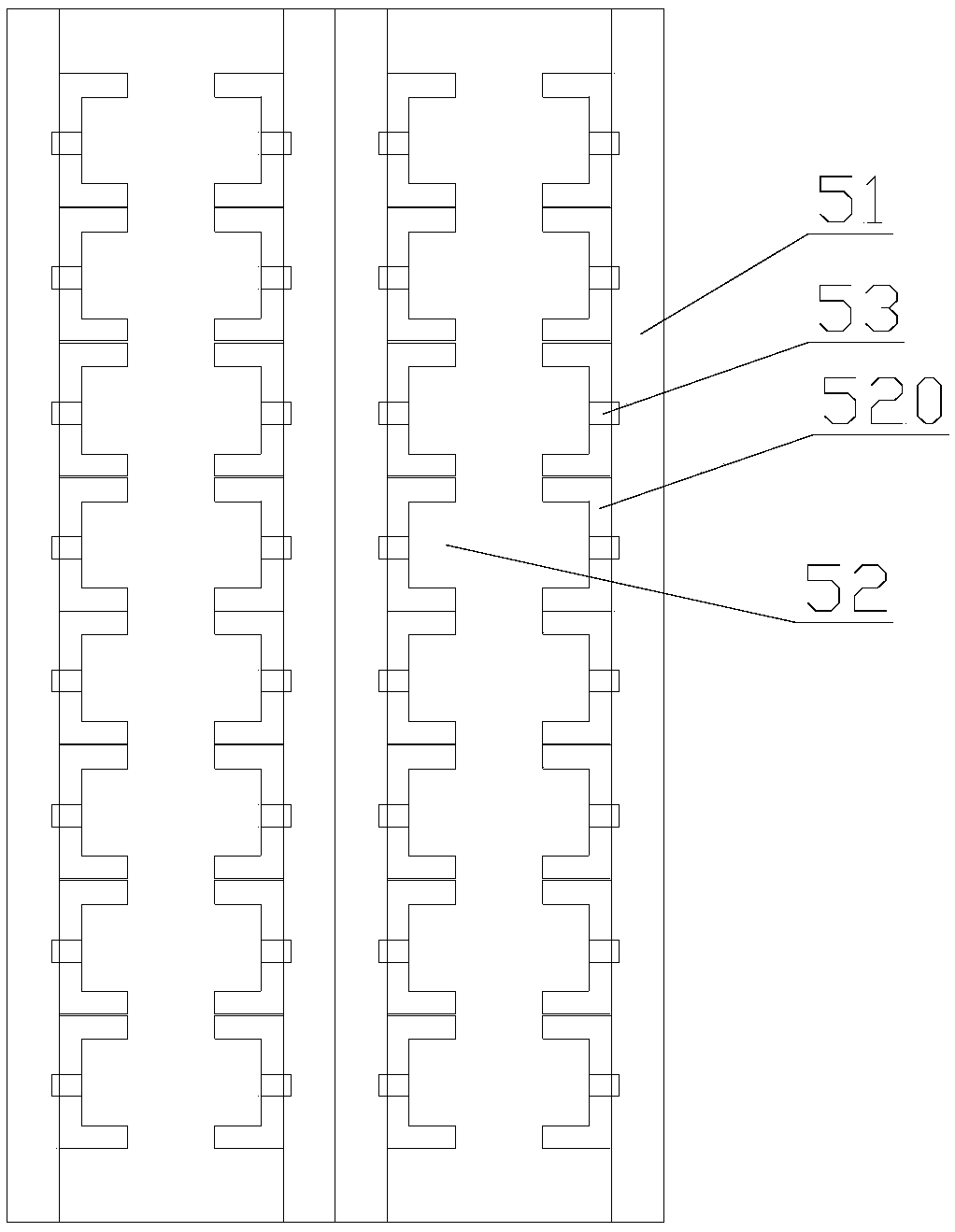

[0018] refer to figure 1 , 2 And 3, a novel bearing cleaning device of the present invention comprises a cleaning box 1, a frame 2, a conveyor belt 3, a cleaning mechanism 4, a bearing fixing mechanism 5, and a discharge box 6, and the cleaning box 1 is installed on the frame 2, The front and rear sides of the cleaning box 1 are respectively provided with a cleaning box inlet 11 and a cleaning box outlet 12, the conveyor belt 3 is arranged through the cleaning box 1, and the two ends of the conveyor belt 3 extend to the cleaning box inlet 11 and the cleaning box outlet 12 respectively. In addition, the conveyor belt 3 is provided with a bearing fixing mechanism 5, and the front end of the cleaning box outlet 12 is provided with a discharge box 6, and the cleaning mechanism 4 includes a water tank 41, several spray heads 42, brush devices 43 and control device 44, the water tank 41 is installed above the inside of the cleaning tank 1, the shower head 42 is arranged at the bott...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com