Six-degree-of-freedom compliant joint driven by pneumatic muscles

A technology of pneumatic muscles and degrees of freedom, applied in manipulators, program-controlled manipulators, manufacturing tools, etc., can solve problems such as less degrees of freedom, large volume, and high rigidity, so as to increase the range of angular motion, increase motion compliance and position The effect of increasing the range of adjustable posture and increasing the range of adjustable posture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The specific implementation manners of the present invention will be further described below in conjunction with the drawings and technical solutions.

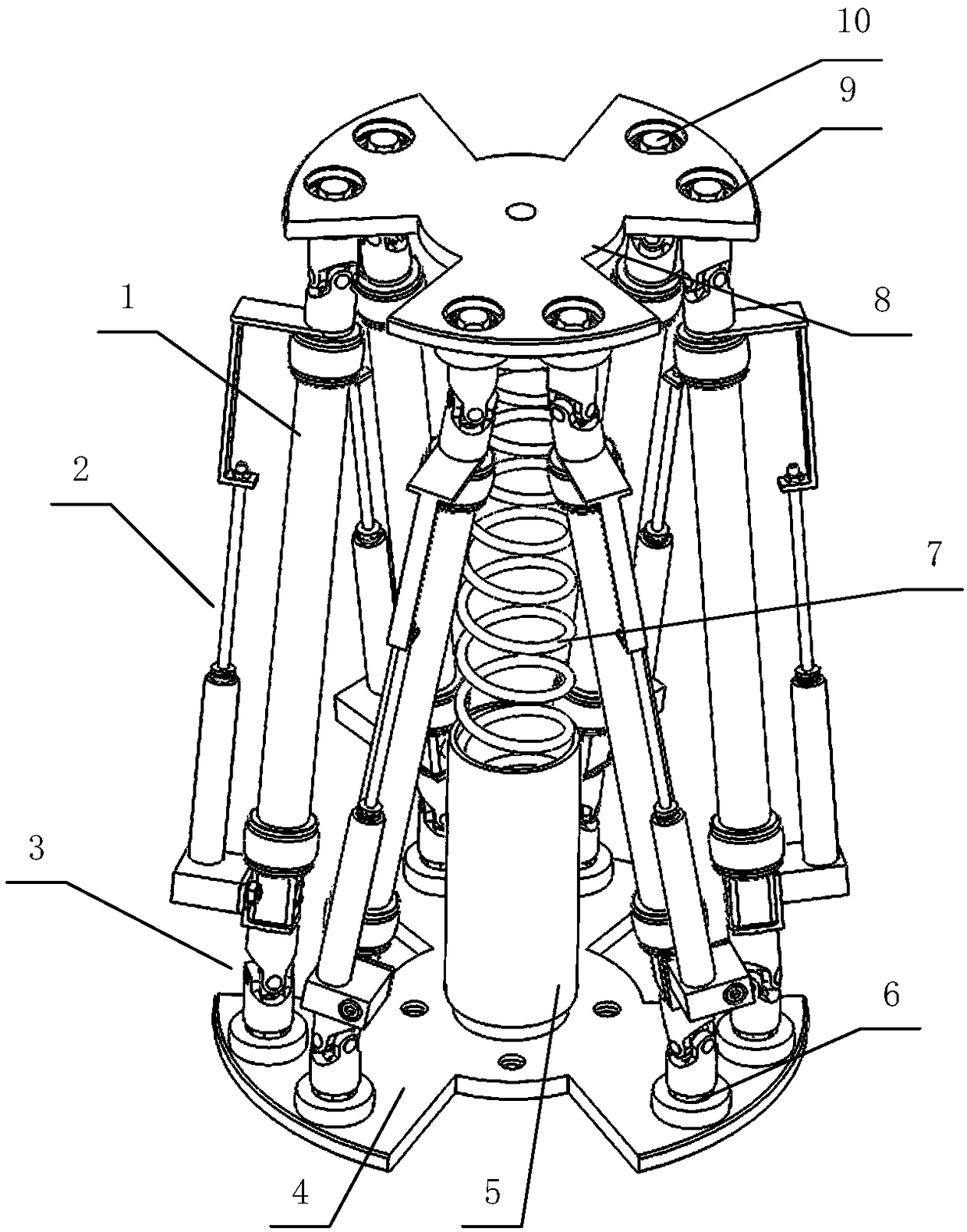

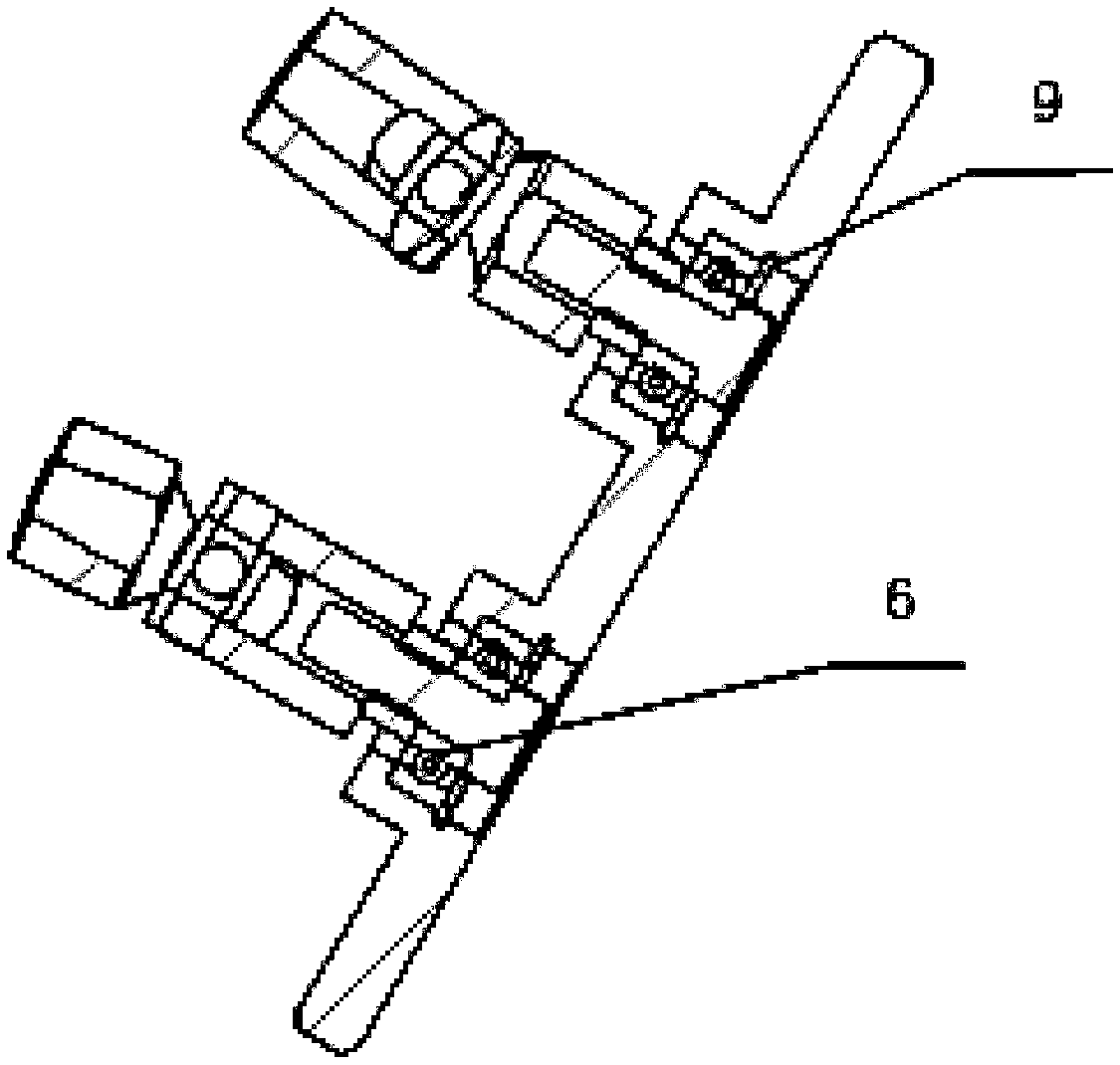

[0023] Such as figure 1 and image 3 As shown, a six-degree-of-freedom compliant joint driven by a pneumatic muscle includes a pneumatic muscle 1, a displacement sensor 2, a universal joint coupling 3, a static platform 4, a lower sleeve 5, a deep groove ball bearing 6, and a supporting pressure spring 7 and moving platform 8.

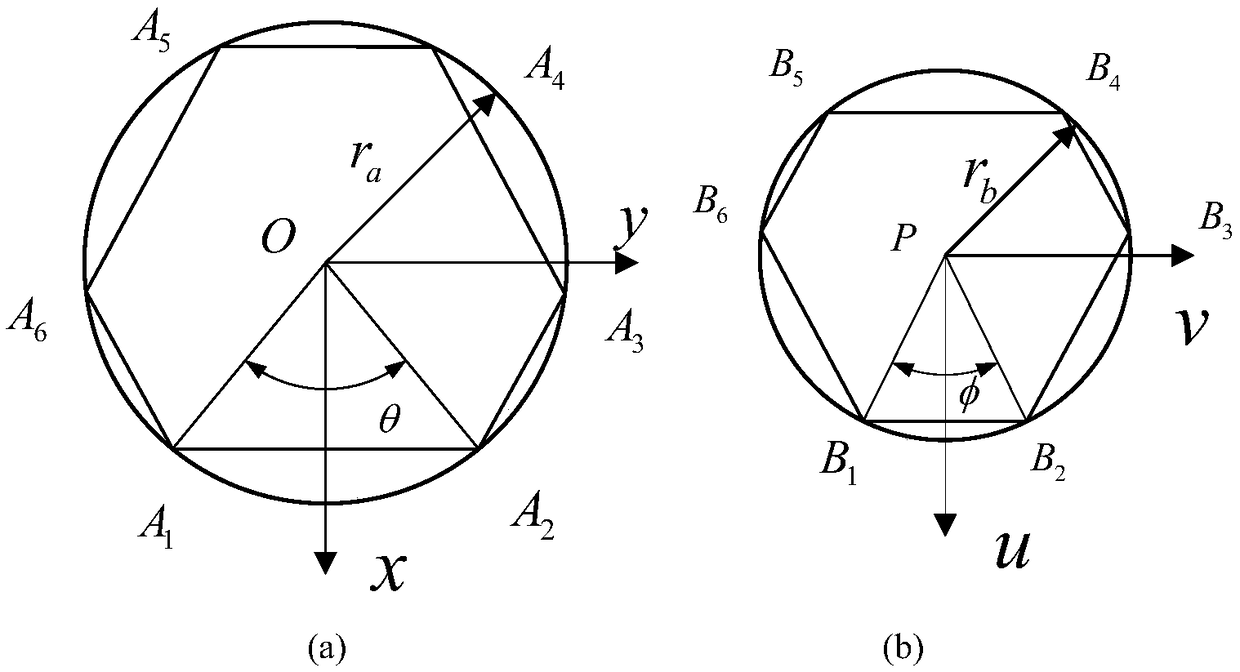

[0024] The moving platform 8 is provided with three groups of reaming holes, each group of reaming hole spacing is 120 degrees, which meets the Stewart characteristic distribution, and each group of reaming holes includes two identical reaming holes, and the radius of any reaming hole from the center point of the moving platform 8 is R1; the static platform 4 is provided with three groups of reaming holes, each group of reaming hole spacing is 120 degrees, which meets the Stewart characteristi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com