Mixed hydrolysis device and method for waste plastics

A technology of waste plastic and hydrolysis device, which is applied in the field of environmental protection and achieves the effects of good safety controllability, improved degradation efficiency, and longer requirements for degradation reaction time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Below in conjunction with accompanying drawing and specific embodiment the invention is further introduced:

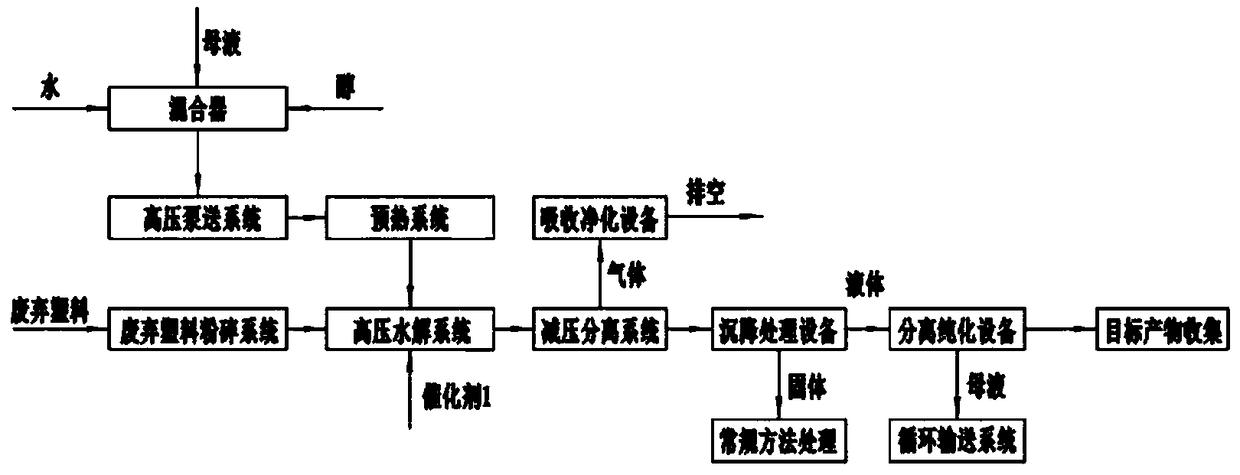

[0035] refer to figure 1 According to the present invention, a mixed hydrolysis device for waste plastics includes: a high-pressure hydrolysis system, a waste plastics crushing system and a batching pumping system. Among them, the high-pressure hydrolysis system is the main place for the mixed hydrolysis reaction of waste plastics, and the time of the mixed hydrolysis reaction can be set and adjusted according to specific needs; the waste plastics crushing system is connected with the feed port of the high-pressure hydrolysis system for The plastic is crushed and sent to the high-pressure hydrolysis system; the ingredient pumping system is used to deliver the ingredients of water, mother liquor and alcohol to the high-pressure hydrolysis system after preheating.

[0036] Preferably, the high-pressure hydrolysis system is a conventional high-pressure reactor equ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com