Manufacturing method of automobile decoration aluminum alloy belt material

A technology for aluminum alloy strips and automobile decoration, applied in the field of aluminum alloy strip manufacturing, can solve problems such as high surface roughness, punching cracks, etc., to achieve stable product quality, solve punching cracks, and ensure the effect of surface brightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

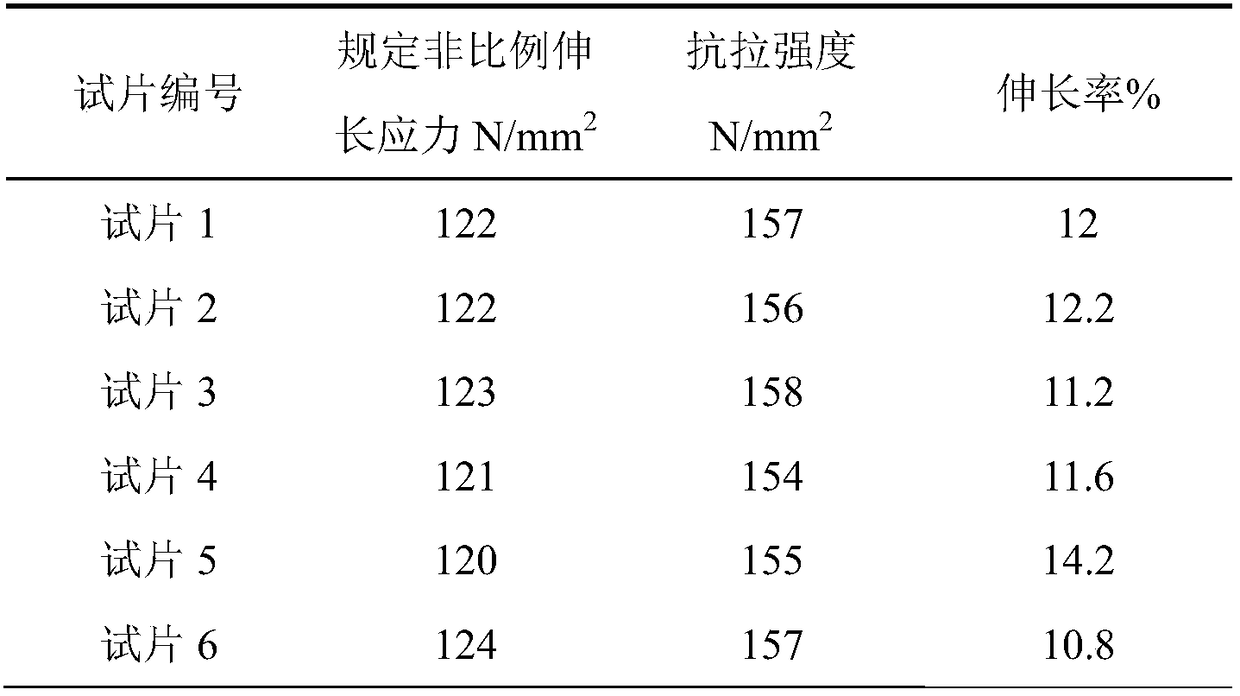

Examples

specific Embodiment approach 1

[0014] Specific Embodiment 1: This embodiment is a method for manufacturing an aluminum alloy strip for automobile decoration, which is specifically completed according to the following steps:

[0015] 1. Preparation of raw materials: According to the mass fraction of Mn in the aluminum alloy strip for automobile decoration is 0.03% to 0.06%, the mass fraction of Mg is 0.8% to 1.1%, and the balance is Al to prepare the smelting raw materials, and ensure that the automobile decoration The mass fraction of Si in the aluminum alloy strip is <0.6%, the mass fraction of Fe is <0.4%, the mass fraction of Zn is <0.04%, and the mass fraction of Ni is <0.01%;

[0016] 2. Melting and casting: smelting the smelting raw materials prepared in step 1 to obtain aluminum alloy solution, and then casting at a casting temperature of 680°C to 720°C and a casting speed of 55mm / min to 60mm / min, casting cooling water during the casting process The force is 0.003MPa~0.1MPa, and the temperature of ca...

specific Embodiment approach 2

[0021] Specific embodiment two: the difference between this embodiment and specific embodiment one is: in step one, the mass fraction of Mn is 0.03%, the mass fraction of Mg is 0.9% and the balance is Al is ready to smelt raw materials. Others are the same as the first embodiment.

specific Embodiment approach 3

[0022] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that in step 2, casting is performed at a casting temperature of 690° C. and a casting speed of 55 mm / min. Others are the same as those in Embodiment 1 or 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com