Papermaking drying device

A drying device and drying cylinder technology, which is applied in papermaking, papermaking, textiles and papermaking, etc., can solve the problems of equipment complexity, limited application scope, and complicated drying cylinder structure, and achieve the effect of improving quality and simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

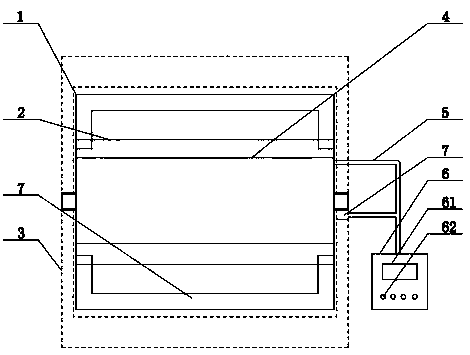

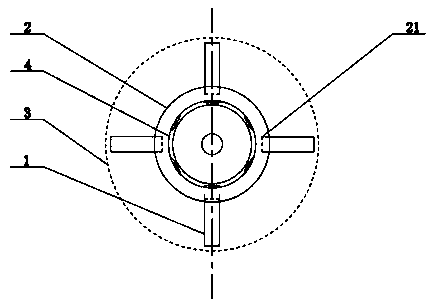

[0017] see Figure 1-Figure 2 As shown, the technical solution adopted in this specific embodiment is: it includes a heat transfer assembly 1, a heat conduction roller 2, a drying cylinder 3, an electromagnetic induction coil 4, a connecting pipe 5, a heater 6, and a temperature sensor 7; Component 1, heat conduction roller 2, electromagnetic induction coil 4, and temperature sensor 7 are all arranged inside the drying cylinder 3. There are four sets of heat transfer components 1, and the four sets of heat transfer components 1 are respectively arranged on the surface of the heat conduction roller 2. , the electromagnetic induction coil 4 is arranged inside the heat conduction roller 2, and the temperature sensor 7 is arranged on the right end of the heat conduction roller 2, and the heat conduction roller 2 and the temperature sensor 7 are connected to the heater 6 through the connecting pipe 5; the heat conduction roller 2 The surface of the surface is provided with installa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Side wall thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com