Drying device for papermaking

A drying device and drying cylinder technology, which is applied in papermaking, papermaking machines, textiles and papermaking, etc., can solve the problems that the moisture cannot be dried in time, the gloss, color and other physical properties of the front and back of the paper cannot be kept consistent, etc. Achieve color and other physical properties retention, color and other physical properties consistency, and uniform moisture distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

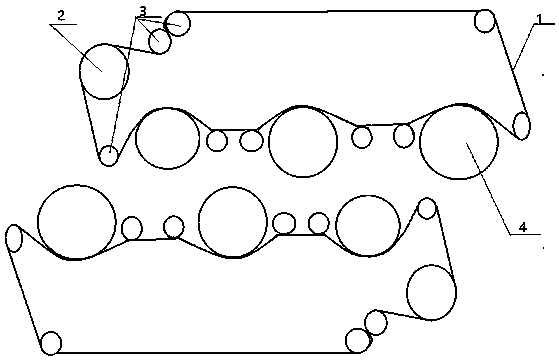

[0018] Below in conjunction with accompanying drawing, the present invention is made following explanation:

[0019] see figure 1 , which is a schematic diagram of the structure of the upper and lower dryer wire loops for the papermaking of the front wire dryer of the present invention,

[0020] The dryer fabric circuit includes a dryer fabric 1 and a number of guide rollers 3. The dryer fabric is positioned and wound on the drying cylinder 4 through a number of guide rollers. Each of the dryer fabrics 1 forms a closed loop. The front of the dryer fabric 1 is closely attached to the surface of the drying cylinder. , The drying net 1 is driven by the drying cylinder 4 to do endless circulation, the drying net 1 is a polyester woven drying net;

[0021] this invention figure 1 Only the front group of dryers is drawn, and the basic structure of the rear group of dryers is the same as that of the front group of dryers, which will be briefly explained here.

[0022] The structur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com