Overhead type pump valve system in self-heating tank

A self-heating, in-tank pump technology, applied to roads, road repair, roads, etc., can solve the problems of increasing the weight of asphalt pavement maintenance vehicles, increasing the manufacturing cost and use cost of asphalt pavement maintenance vehicles, and achieve the effect of avoiding electric shock

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments, and the content of the present invention is not limited to the following embodiments.

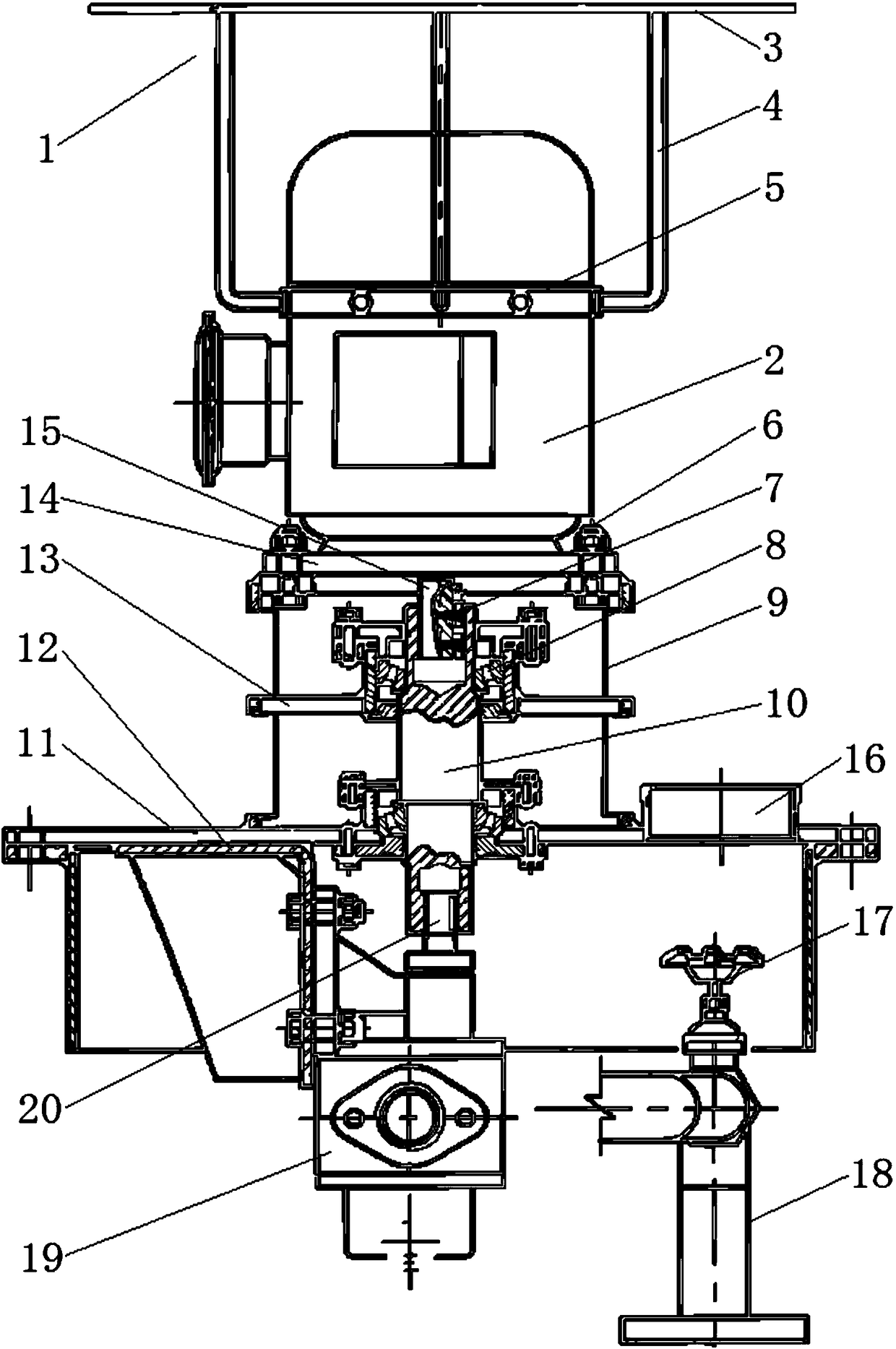

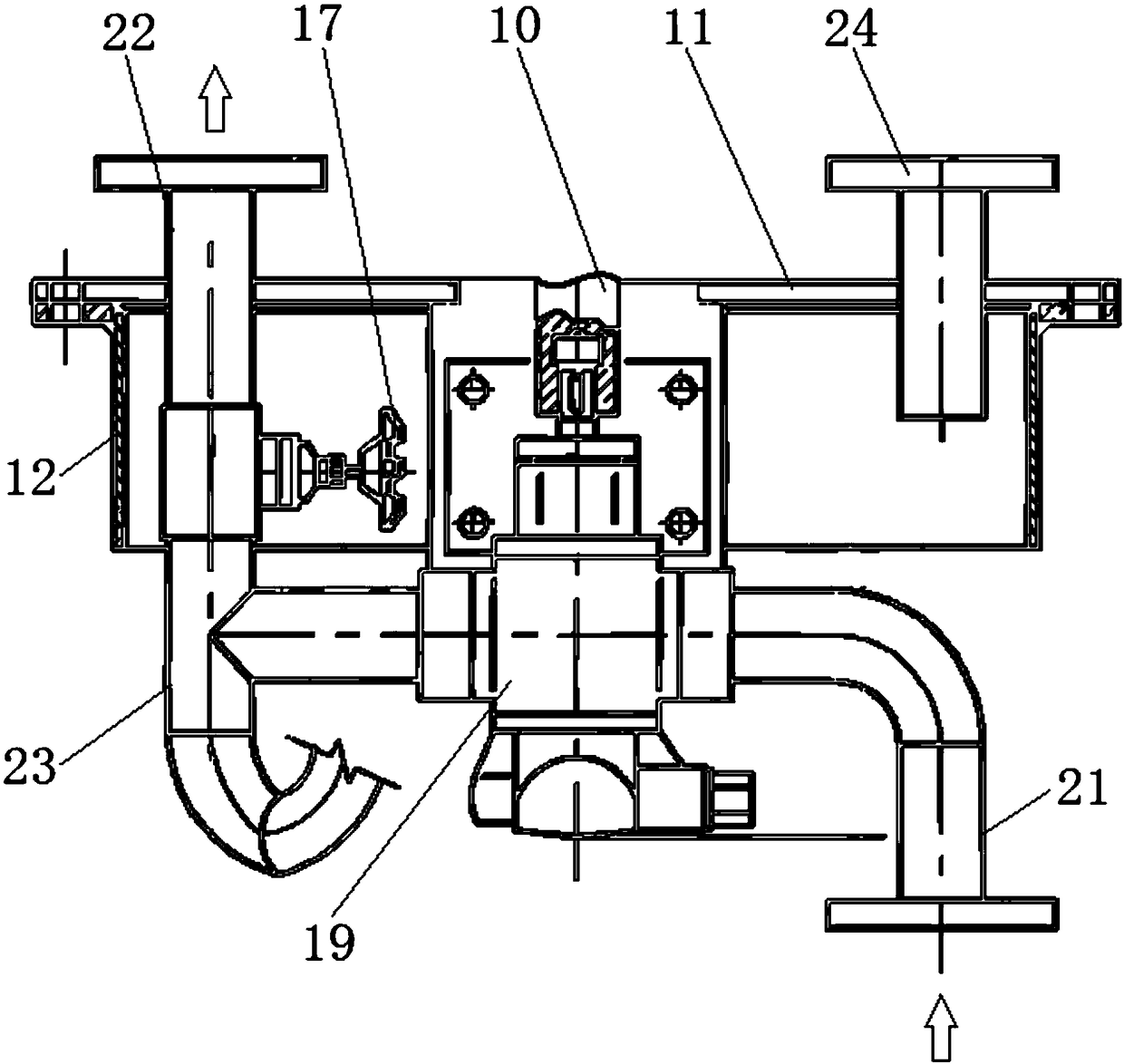

[0028] The pump valve system in the top-mounted self-heating tank provided by the invention has a structure such as figure 1 As shown, the motor 2, the pump 19 driven by the motor 2 and the asphalt pipe 18 communicated with the pump 19 are included. The motor 2, the pump 19 and the asphalt pipe 18 are all installed on the top of the asphalt tank 11, and the motor 2 passes through the support pipe 9. and the support flange 14 are installed on the top of the asphalt tank 11 and are positioned outside the asphalt tank 11, the support pipe 9 and the support flange 14 are connected by threaded fasteners 6, the top of the motor 2 is equipped with a canopy 1, and the cover of the canopy 1 The area is larger than the cross-sectional area of the motor 2. The canopy 1 is com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com