Track type movable foundation and construction method thereof

A track-type, track-based technology, applied in infrastructure engineering, construction, etc., can solve the problems of waste of materials and increased labor input, and achieve the effects of increasing durability, saving materials and labor, and saving materials and machinery costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

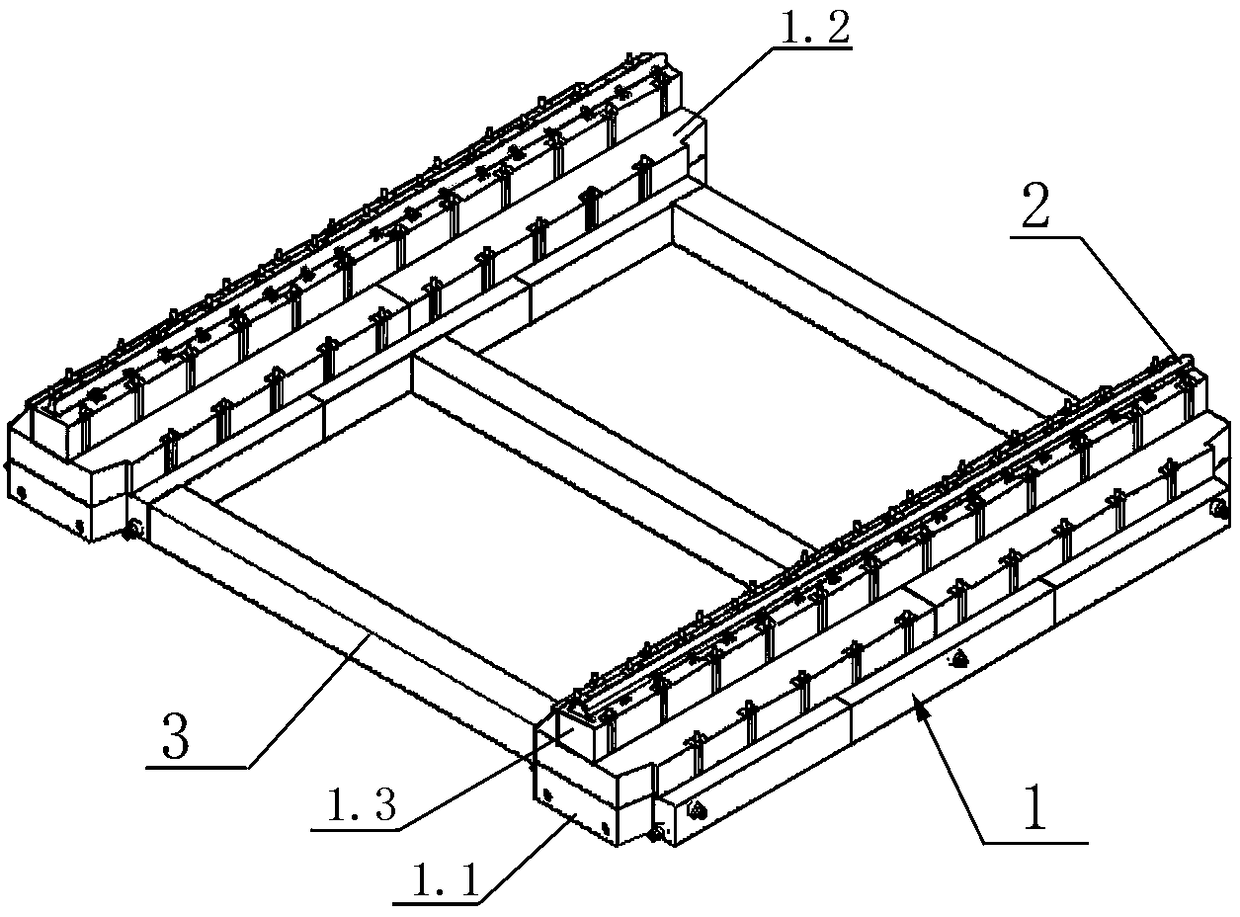

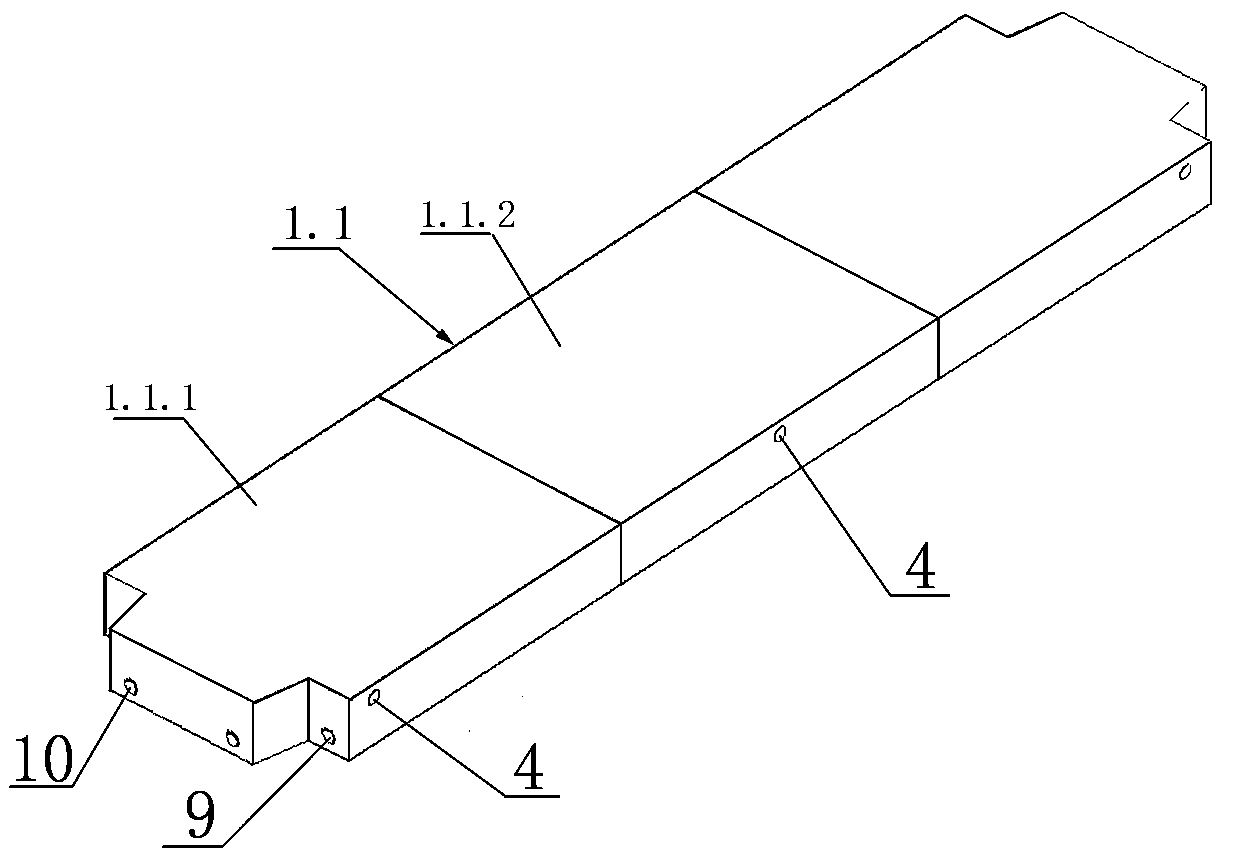

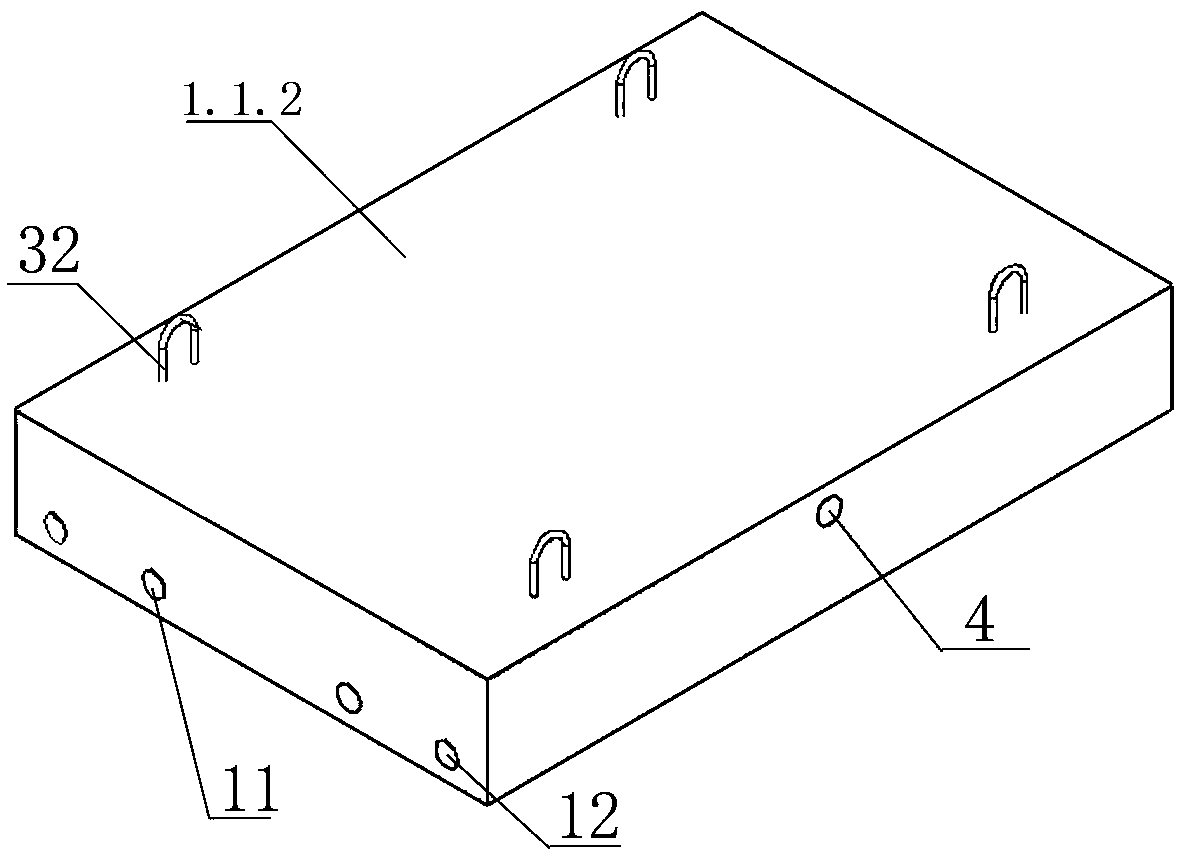

[0065] Such as Figure 1-16 As shown, this track-type tower crane foundation structure includes two track beams 1 arranged in parallel at intervals, a track 2 installed on the top of the track beam 1 and a set of tension beam matching blocks connected between the two track beams 1 3. The track beam 1 includes a base-level matching block 1.1, a middle-level matching block 1.2, and a top-level matching block 1.3 that are detachably connected from bottom to top; The position is provided with a first longitudinal reinforcement hole 4 passing through the base block 1.1; the top block 1.3 is provided with a connecting assembly connecting the track 2; the track 2 is arranged along the long axis of the track beam 1, and It is detachably connected to the top of the top block 1.3 through the connecting assembly; in the tension beam block 3, a second longitudinal hole 6 is provided at the position corresponding to the first longitudinal hole 4 of the base block 1.1, and the tension beam ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com