Sound insulation structure of construction site

A construction site and wall panel technology, applied in the direction of sound insulation, building components, building structures, etc., can solve the problems of complex installation structure and inconvenient installation, and achieve the effect of good sound insulation, convenient transportation and light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

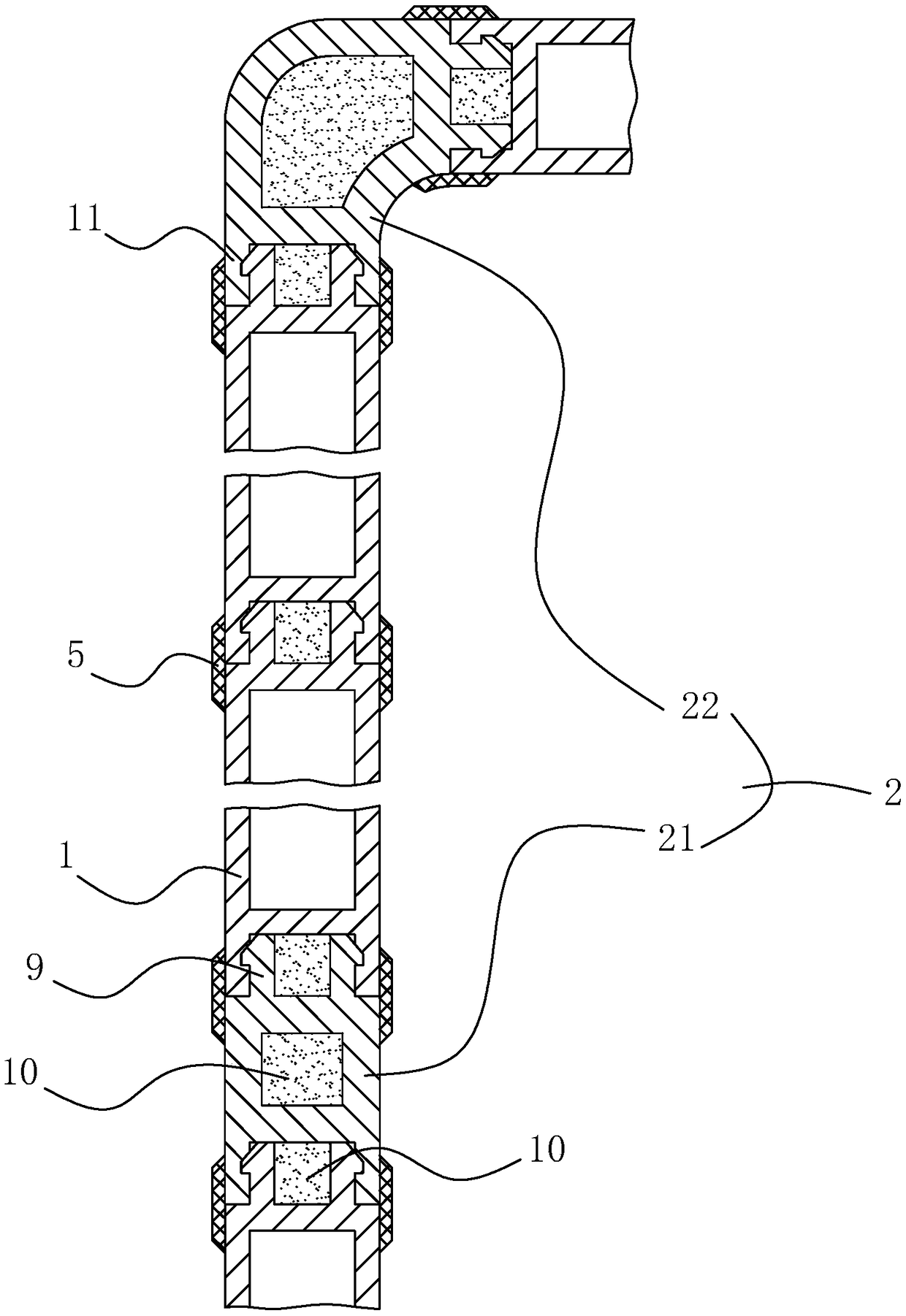

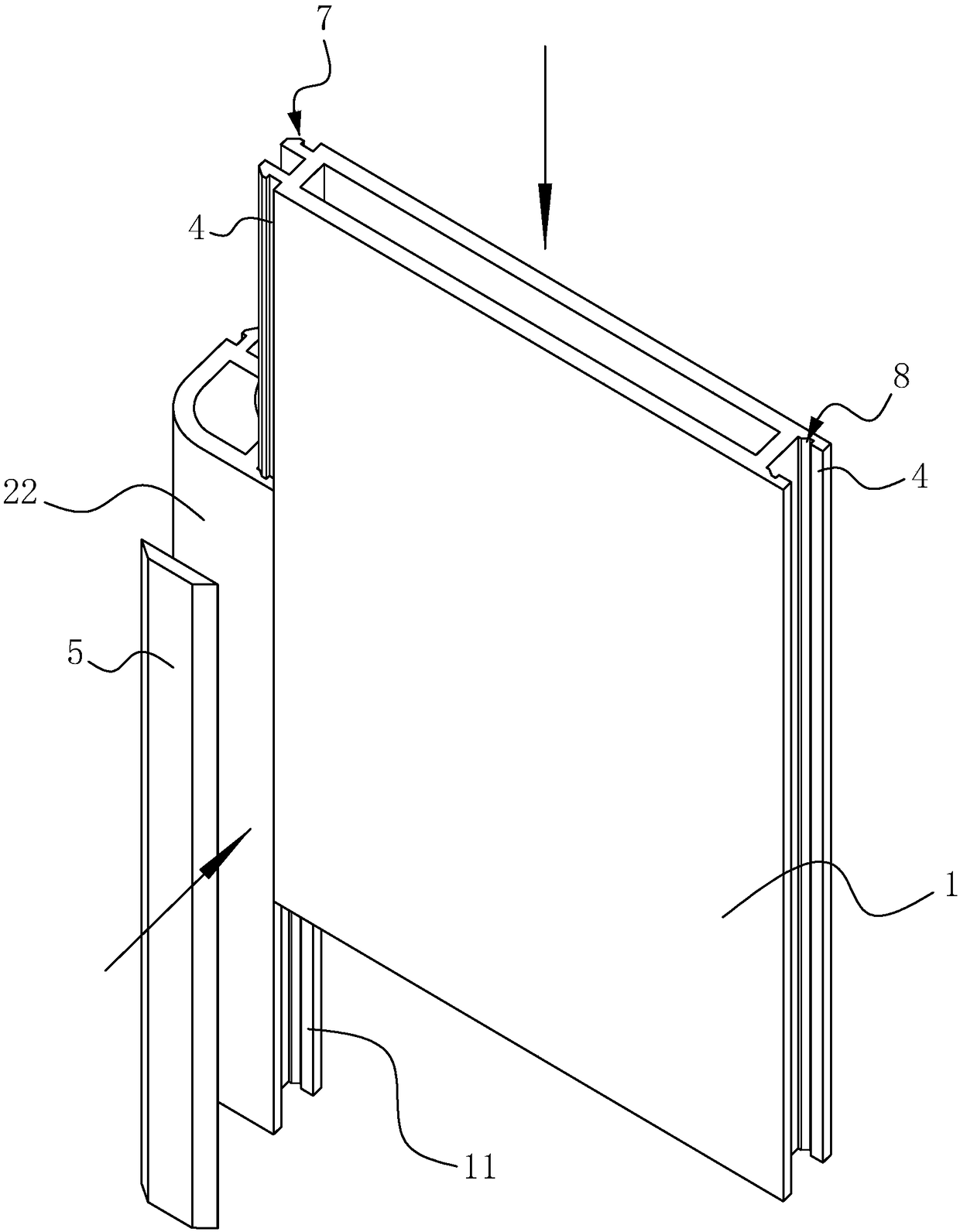

[0036] refer to Figure 1 to Figure 4 for further explanation.

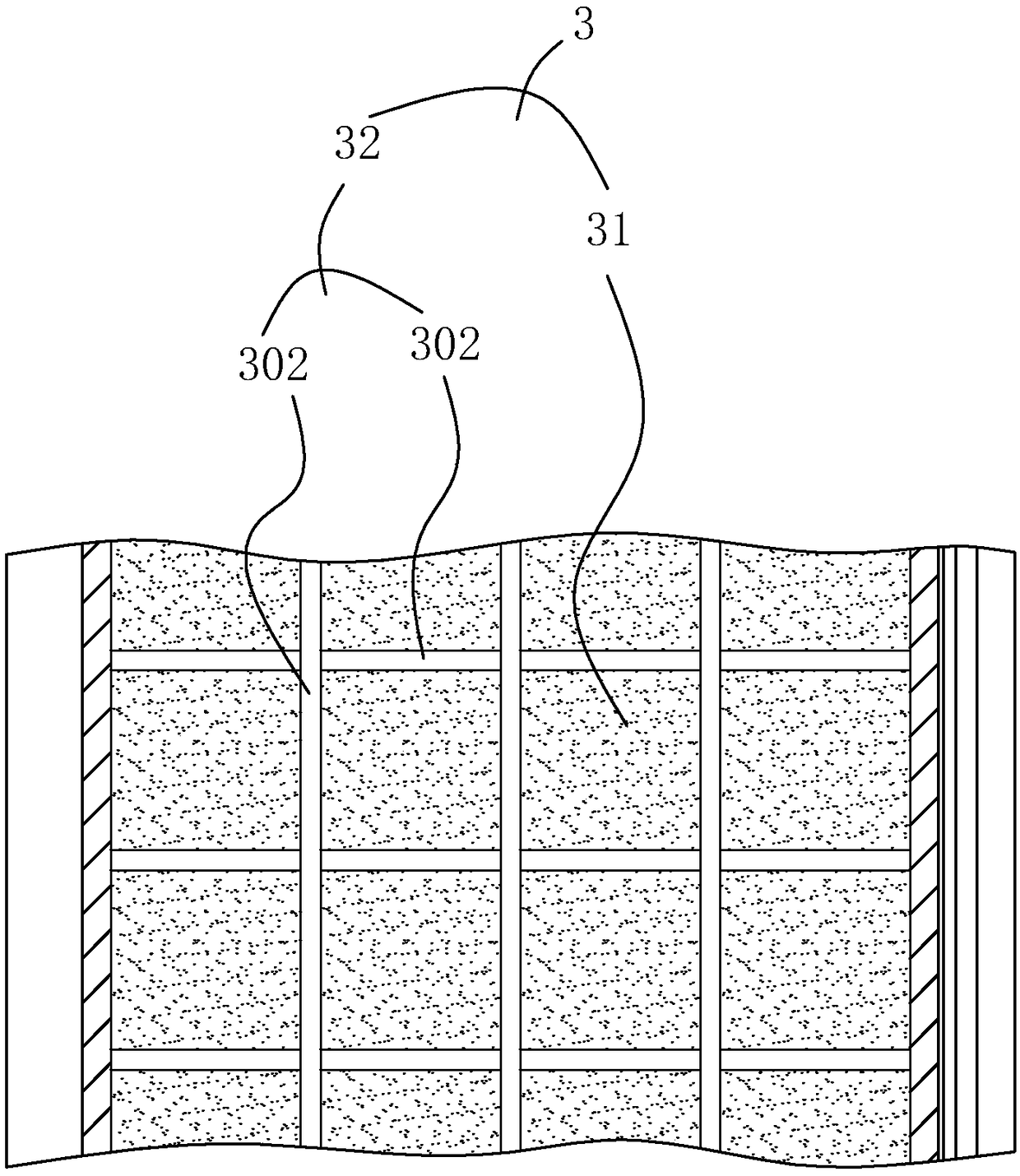

[0037] A construction site room sound insulation structure, such as figure 1 and figure 2 As shown, it includes a wall panel 1 and a column 2. which, combined with image 3 , The interior of the wallboard 1 is hollow and filled with sound-absorbing panels 3 . Both sides of the wallboard 1 are provided along the length direction with guide ribs 4 for sliding engagement with adjacent wallboards 1 , and at the same time, the guide ribs 4 are also slidingly engaged with the columns 2 .

[0038] Specifically, combined with figure 1 and figure 2 The guide ribs 4 located on both sides of the wallboard 1 are arranged in pairs, and the outward end surface of the guide rib 4 on one side is provided with a convex strip 7 along its length direction, and the inner end surface of the guide rib 4 on the other side Along its length direction, there is a groove 8 for the protruding strip 7 to slip and snap into. Wherein...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com