Gas cylinder filling system and method

A gas cylinder and gas technology, applied in the direction of container filling method, container discharge method, equipment loaded into pressure vessels, etc., can solve the problems of cumbersome, storage tank explosion, busy filling station, etc., and achieve simplified filling operation, The effect of avoiding illegal operations and improving filling efficiency and safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

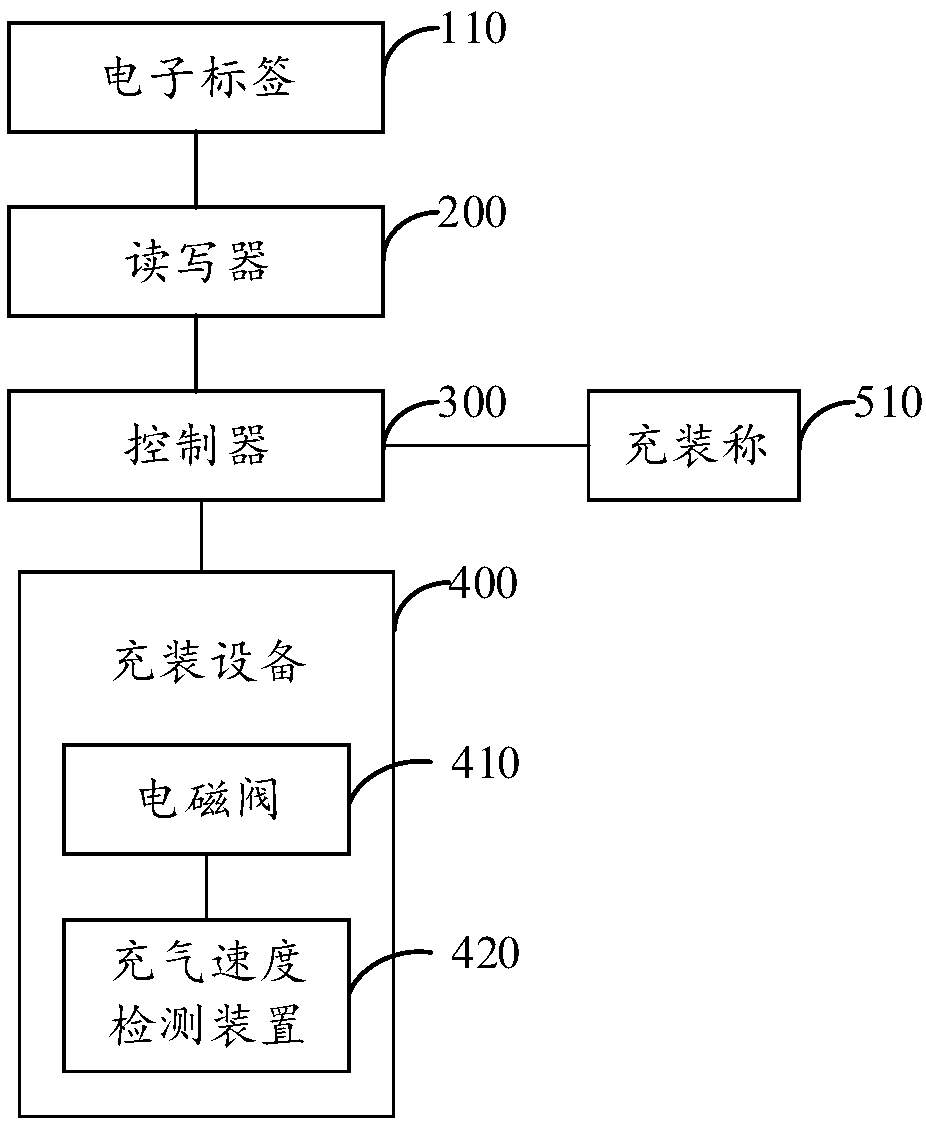

[0038] figure 1 It is a schematic diagram of the gas cylinder filling system provided by Embodiment 1 of the present invention.

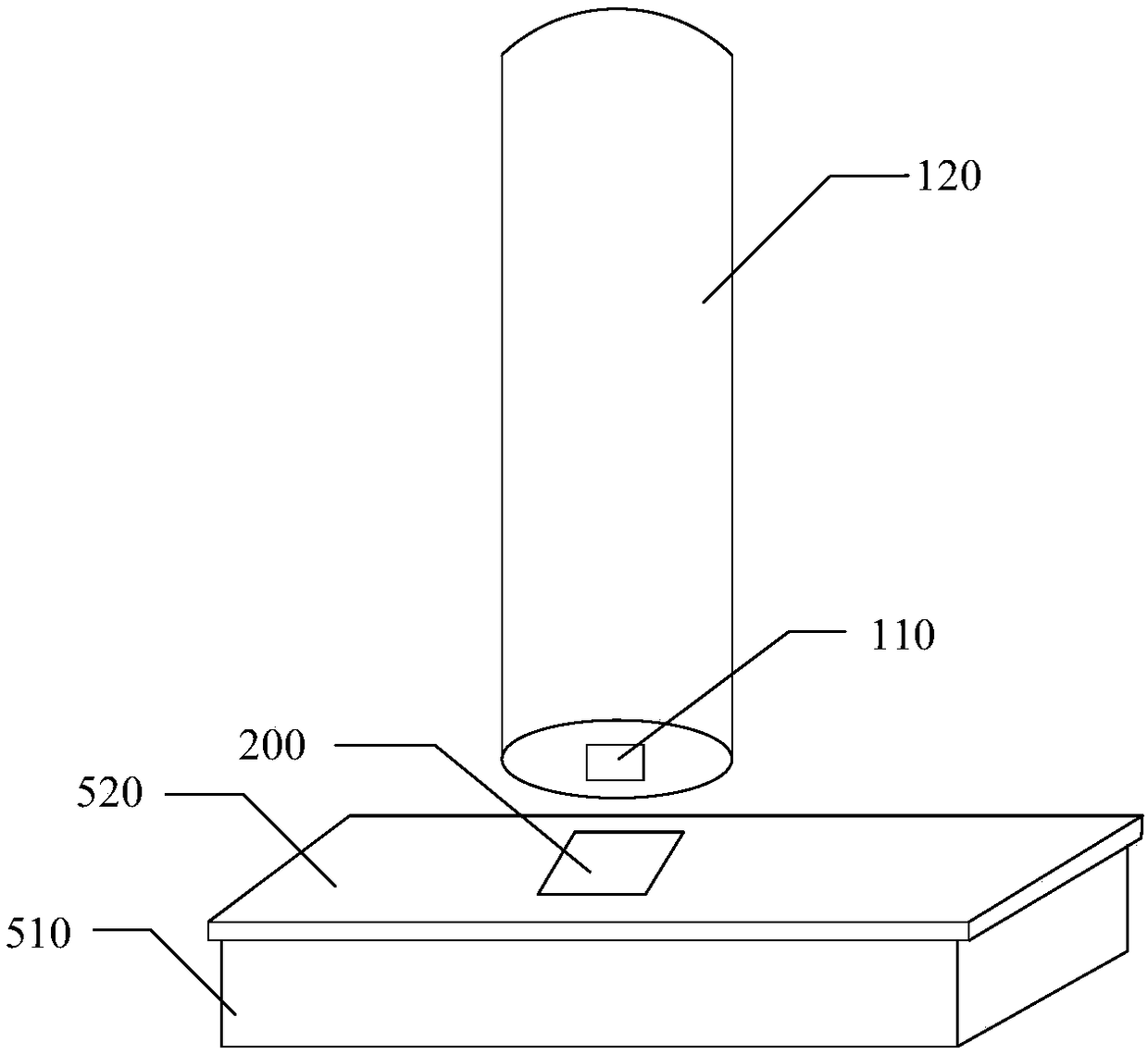

[0039] refer to figure 1 with figure 2 , The gas cylinder filling system includes: electronic tag 110, reader-writer 200, controller 300, filling equipment 400 and filling scale 510, etc.

[0040] The electronic tag 110 is fixedly installed on the bottom of the gas cylinder 120 , and each gas cylinder 120 is correspondingly equipped with a unique matching electronic tag 110 , and the reader-writer 200 is arranged on the surface of the filling scale chassis 520 . The electronic tag 110 cannot be transferred. Once it is attached to the bottom of the gas cylinder 120, the electronic tag 110 will not be usable again if it is transferred by external force; Medium, such as liquefied petroleum gas, oxygen, argon, dimethyl ether and other gases or liquids; when the gas cylinder 120 is placed on the filling scale chassis 520, the reader 200 is close to t...

Embodiment 2

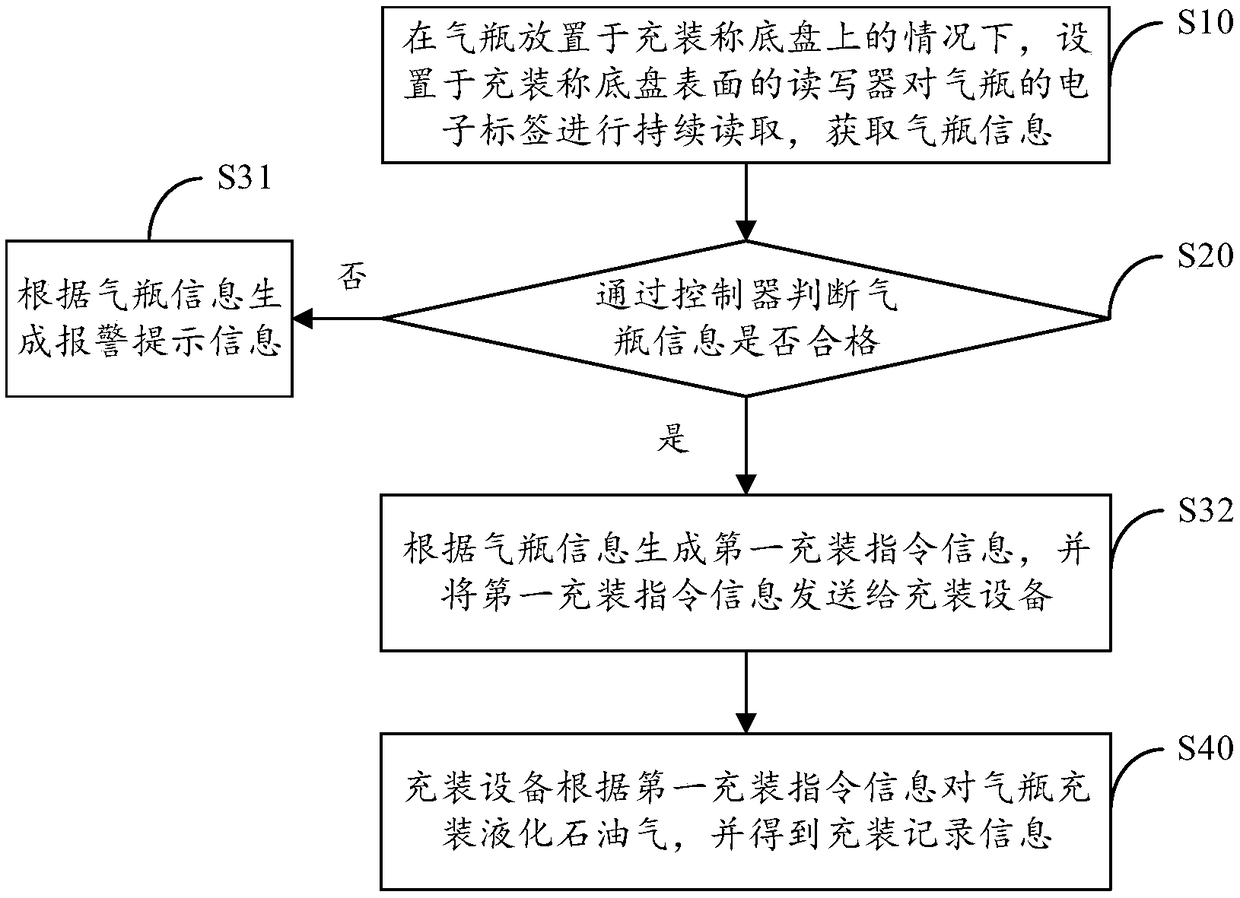

[0049] image 3 It is a flow chart of the gas cylinder filling method provided by Embodiment 2 of the present invention.

[0050] Based on the gas cylinder filling system provided in the above embodiments, this embodiment provides a gas cylinder filling method. refer to image 3 with Figure 4 , the gas bottle filling method comprises the steps:

[0051] Step S10, when the gas cylinder is placed on the chassis of the filling scale, the reader set on the surface of the chassis of the filling scale continuously reads the electronic tag of the gas cylinder to obtain the information of the gas cylinder;

[0052] Specifically, the reader can read the electronic tags continuously and uninterruptedly, which can avoid the situation of reading the A tag but filling the B gas cylinder, or the situation of changing the gas cylinder during filling.

[0053] Step S20, judge whether the gas cylinder information is qualified through the controller; if not qualified, then execute step S31...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com