Grain surface moving device platform for grain depot

A mobile device and grain noodle technology, applied to measuring devices, sampling devices, sampling, etc., can solve the problem of low passability and achieve the effect of increasing passability and reducing resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

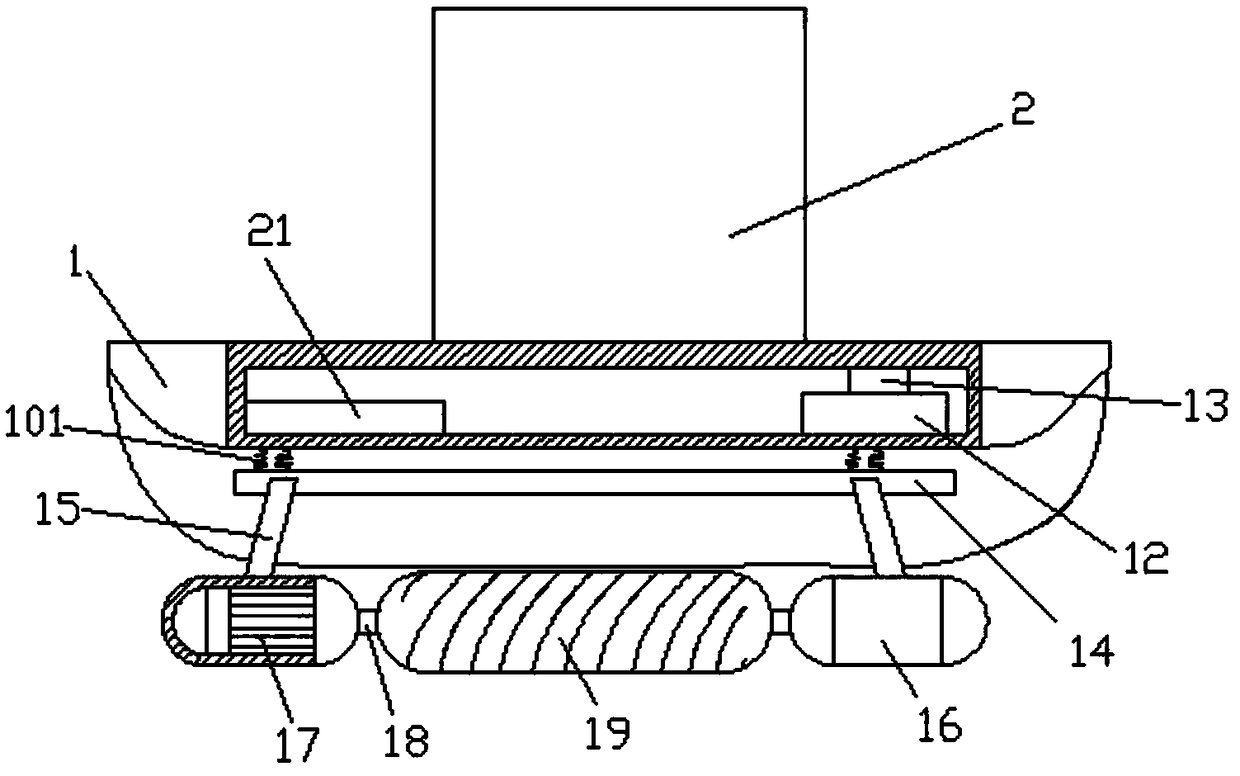

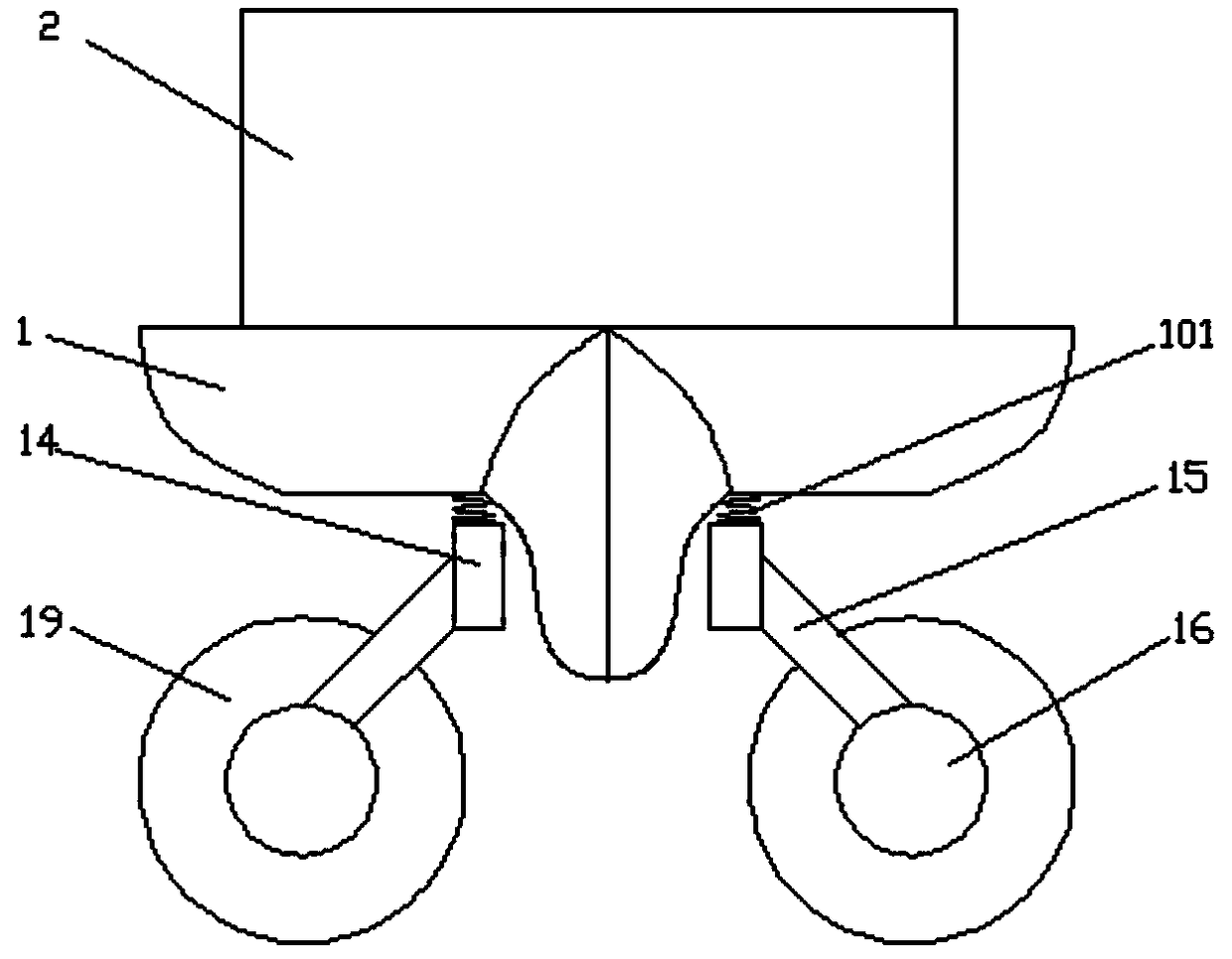

[0025] like figure 1 Shown; A kind of mobile device platform for grain surface of grain depot, comprises base case 1 and the automatic detection system 2 of grain heap installed on the top of base case 1, the controller 12 of automatic detection system 2 of grain heap is installed in base case 1, controls The device 12 is equipped with a wireless module 13, and the bottom surface of the base box 1 is a fish maw-shaped structure, which reduces the resistance between the base box and the grain surface. When the spiral wheel sinks into the grain layer, the fish maw-shaped structure can play a supporting role. To reduce the sinking of the spiral wheel, support frames 14 are installed on both sides of the base box 1, and the front and rear ends on both sides of the support frame 14 are respectively connected to the support rods 15, and the other end of the support rods 15 is connected to the motor box 16, and the support rods prop up the base case. Make the lower bottom surface of ...

Embodiment 2

[0034] like figure 1 Shown; A kind of mobile device platform for grain surface of grain depot, comprises base case 1 and the automatic detection system 2 of grain heap installed on the top of base case 1, the controller 12 of automatic detection system 2 of grain heap is installed in base case 1, controls The device 12 is equipped with a wireless module 13, and the bottom surface of the base box 1 is a fish maw-shaped structure, which reduces the resistance between the base box and the grain surface. When the spiral wheel sinks into the grain layer, the fish maw-shaped structure can play a supporting role. To reduce the sinking of the spiral wheel, support frames 14 are installed on both sides of the base box 1, and the front and rear ends on both sides of the support frame 14 are respectively connected to the support rods 15, and the other end of the support rods 15 is connected to the motor box 16, and the support rods prop up the base case. Make the lower bottom surface of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com