Electric railway AT traction network AT section fault location method

A technology for electrified railways and positioning methods, which is applied to fault locations, fault detection by conductor type, etc., to achieve high accuracy and good versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

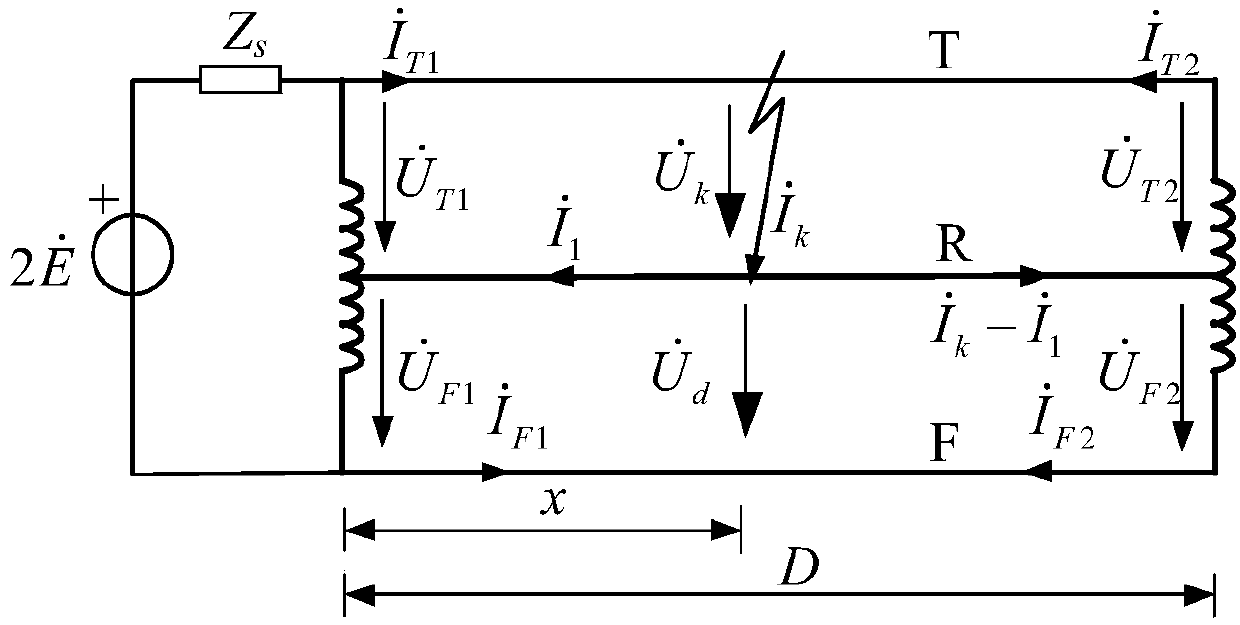

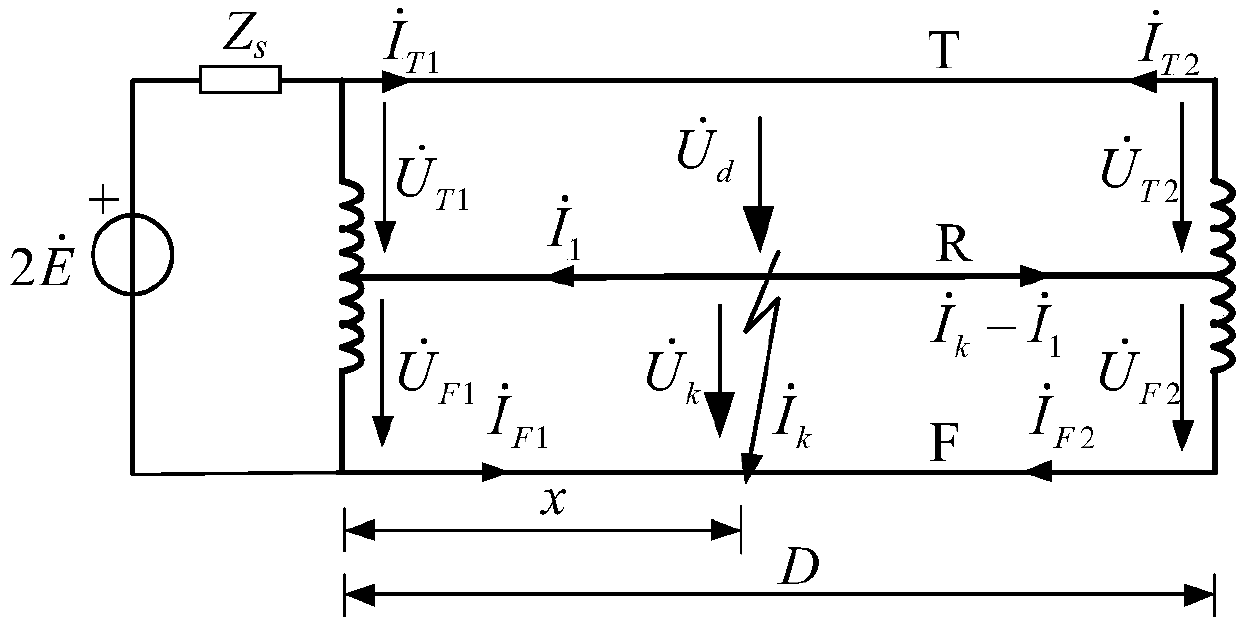

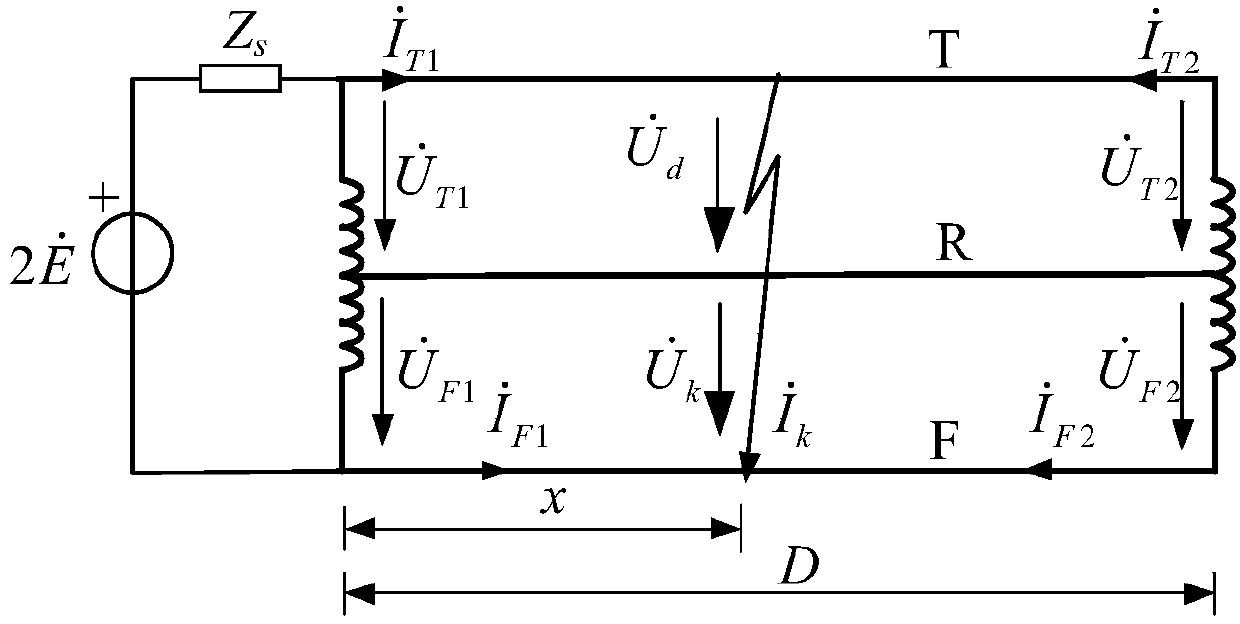

[0024] like figure 1 As shown, let the power supply voltage phasor be The system impedance is Z S , the length of the AT segment of the AT traction network is D, synchronously measure the voltage phasor and current phasor at both ends of the AT segment of the traction network, including the voltage phasor at the head end of the contact line T and the head-end current phasor terminal voltage phasor and terminal current phasors Negative feeder F head-end voltage phasor and the head-end current phasor terminal voltage phasor and terminal current phasors Suppose a TR short circuit occurs at the distance x from the head end of the AT segment (D-x from the short end of the AT) km, write the circuit equation, and solve the fault location:

[0025]

[0026]

[0027] In the formula: the units of length D and x are km, and the units of various impedance Z are Ohm / km; each head-end voltage phasor and terminal voltage phasors The unit is V, each head-end current...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com