Silk-screen printing mask-making technology

A technology of screen printing and screen, which is applied in the field of screen printing plate making technology, can solve the problems of insufficient smooth and tidy edges of the screen printing plate image, insufficient exposure time, and low resolution of photosensitive adhesive, so as to reduce the amount of coating and exposure time, to ensure uniformity, and to quickly repair the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to make the content of the present invention clearer and easier to understand, the content of the present invention will be further described below. Of course, the present invention is not limited to this specific embodiment, and general replacements known to those skilled in the art also fall within the protection scope of the present invention. The beneficial effects of the present invention will be described in detail in conjunction with the embodiments.

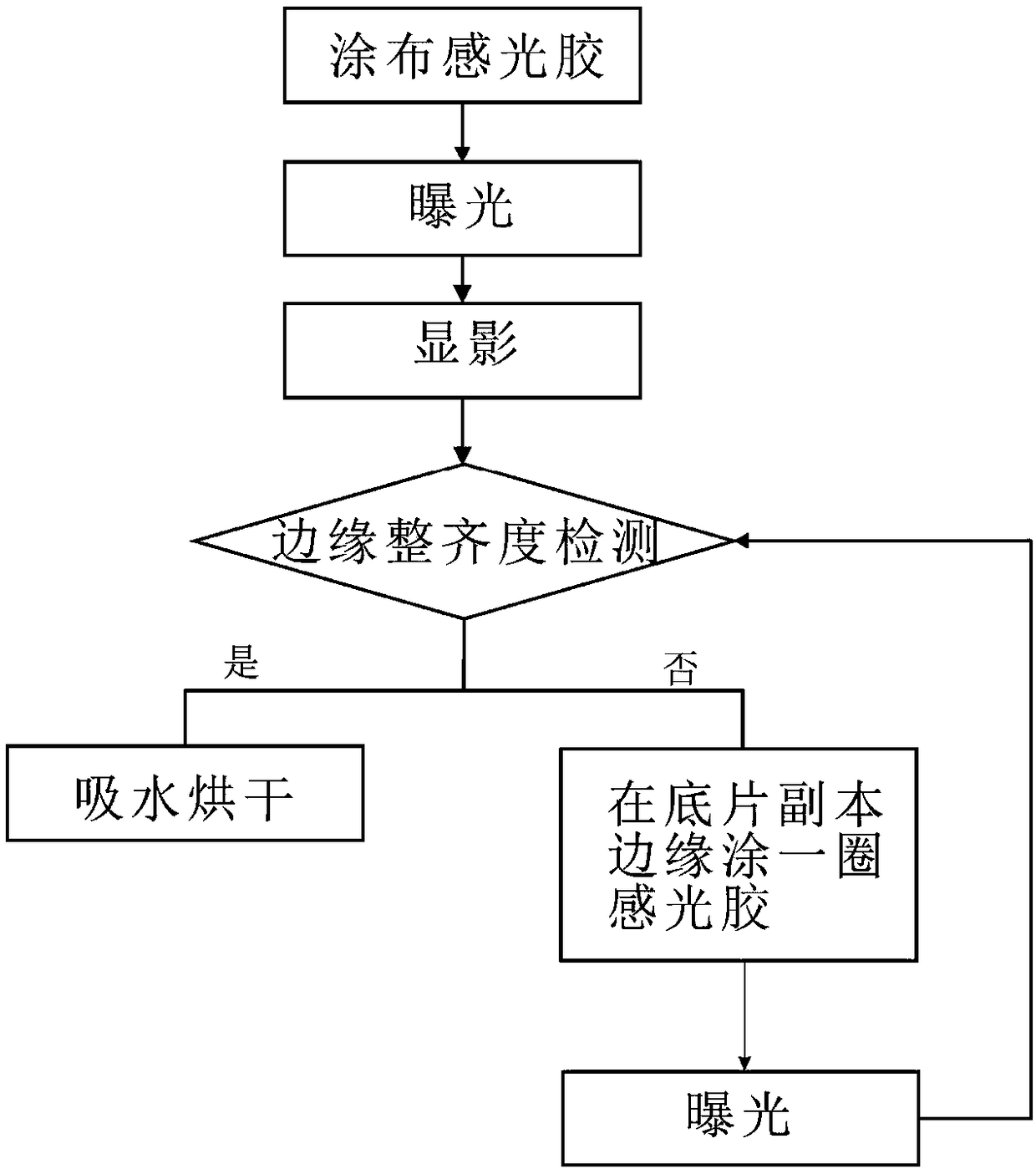

[0019] like figure 1 As shown, the present invention provides a kind of screen printing plate-making process, comprises the following steps:

[0020] S1. Coating photosensitive glue, evenly coating the photosensitive glue on the screen and drying it thoroughly;

[0021] S2, put the negative film on the printing surface of the screen, and then expose it in a vacuum exposure machine;

[0022] S3. Remove the screen from the exposure machine, remove the negative film, first moisten the surface of the screen ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com